Anion exchange membrane with high anion permeability and high ion selectivity, preparation method and application thereof

An anion-exchange membrane and ion-selective technology, which is applied in the field of electrodialysis process, can solve the problems of pouring film formation and anion-exchange membrane difficulty, and achieve high anion permeability, good mechanical properties and performance stability, and good performance stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] (1) Preparation of BPPO with DBM of 0.1

[0035] Dissolve PPO (12.00g, methyl mole number 200mmol) in 100ml of chlorobenzene, add N-bromosuccinimide NBS (3.56g, 20mmol) and azoisobutyronitrile AIBN (0.22g, 1.33mmol) , react at 135°C for 2.5h, use 500 ml of methanol as the reaction solution to obtain a light yellow solid, filter and wash three times with methanol, dry in the air at 60°C and vacuum-dry to obtain brominated poly-2,6-dimethylphenyl ether with a DBM of 0.1 ( BPPO).

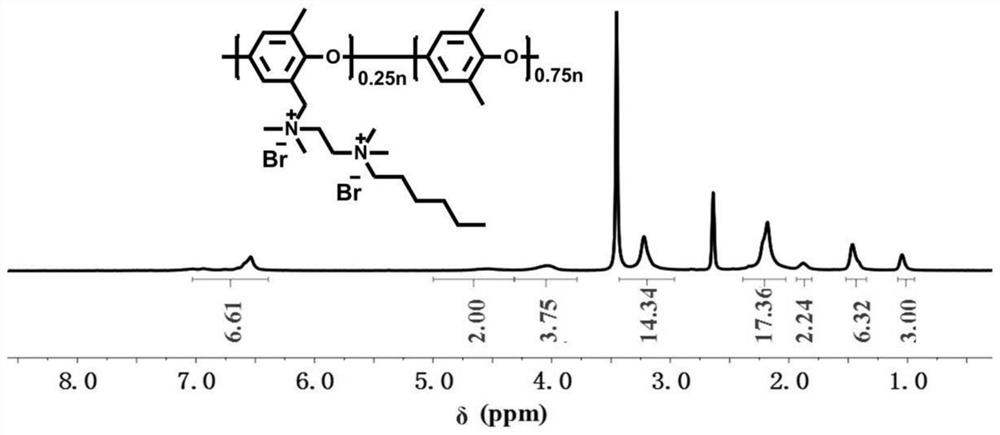

[0036] (2) single ion quaternization reagent a) preparation

[0037]Dissolve 1-bromohexane (10mmol, 1.65g) in 30mL ethyl acetate, add N,N,N',N'-tetramethylethylenediamine (11mmol, 1.28g), and stir the reaction at 30°C for 48h After filtration, a light yellow solid was obtained, and the light yellow solid was washed with 50 mL of ethyl acetate and then dried to obtain quaternization reagent a): N-(2-(dimethylaminoethyl)-N,N-dimethylhexyl- 1-ammonium bromide, the structural formula is as follow...

Embodiment 2

[0044] (1) Preparation of BPPO with DBM of 0.15

[0045] Dissolve PPO (12.00g, methyl mole number 200mmol) in 100ml of chlorobenzene, add N-bromosuccinimide NBS (5.34g, 30mmol) and azoisobutyronitrile AIBN (0.32g, 2.00mmol) , react at 135°C for 2.5h, use 500 ml of methanol as the reaction solution to obtain a light yellow solid, filter and wash three times with methanol, dry in the air at 60°C and vacuum-dry to obtain brominated poly-2,6-dimethylphenyl ether with a DBM of 0.15 ( BPPO).

[0046] (2) single ion quaternization reagent) a preparation

[0047] Single ion quaternization reagent a) is prepared with the same example 1 (2).

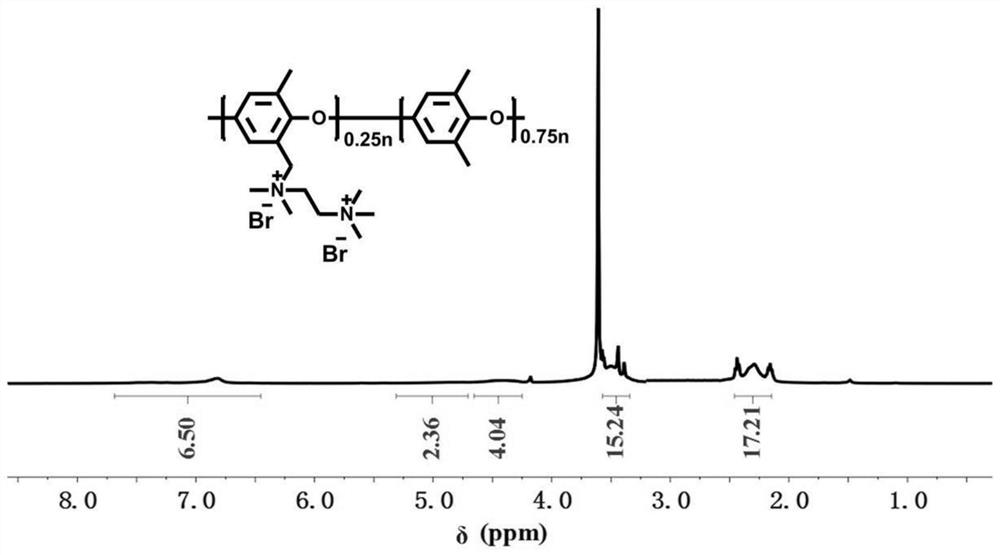

[0048] (3) Preparation of tandem dication side chain type polyphenylene ether anion exchange membrane QPTa-2 linked by hydrophobic alkyl groups:

[0049] Dissolve the quaternization reagent a) (1.5mmol, 0.42g) in (23mL) N-methylpyrrolidone, add BPPO (1.32g, bromomethyl mole number 1.5mmol) with a DBM of 0.15, and then stir the reaction at 30°C ...

Embodiment 3

[0053] (1) Preparation of BPPO with DBM of 0.2

[0054] Dissolve PPO (12.00g, methyl mole number 200mmol) in 100ml of chlorobenzene, add N-bromosuccinimide NBS (7.12g, 40mmol) and azoisobutyronitrile AIBN (0.434g, 2.67mmol) , react at 130°C for 3h, use 500ml of methanol for the reaction solution to obtain a light yellow solid, filter and wash three times with methanol, dry in the air at 60°C and vacuum-dry to obtain brominated poly-2,6-dimethylphenylene ether (BPPO) with a DBM of 0.2 ).

[0055] (2) single ion quaternization reagent a) preparation

[0056] Single ion quaternization reagent a) is prepared with the same example 1 (2).

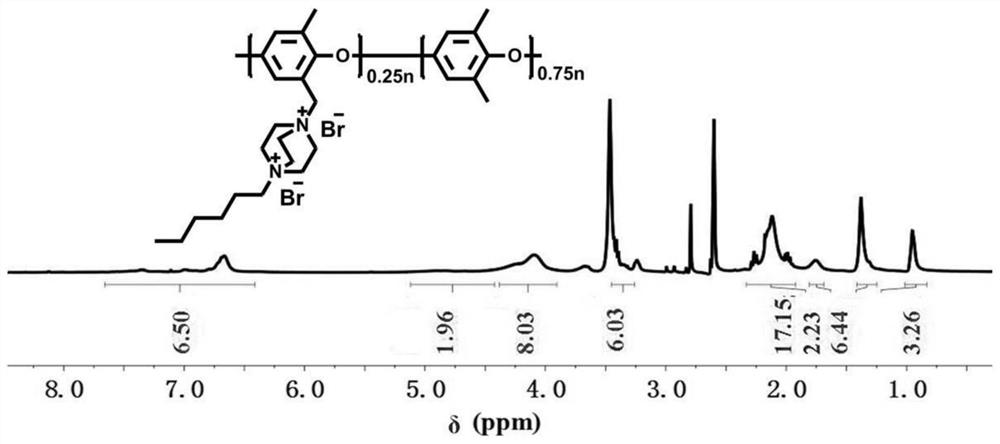

[0057] (3) Preparation of tandem dication side chain type polyphenylene ether anion exchange membrane QPTa-3 linked by hydrophobic alkyl groups:

[0058] Dissolve the quaternization reagent a) (2.0mmol, 0.56g) in (25mL) N-methylpyrrolidone, add BPPO (1.36g, bromomethyl mole number 2.0mmol) with a DBM of 0.2, and then stir the reaction at 40°C ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface resistance | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com