Amphoteric polyether-ether-ketone organic matter and preparation method thereof, amphoteric polyether-ether-ketone ion exchange membrane and iron-chromium redox flow battery

A technology of ion-exchange membrane and polyetheretherketone, which is applied in the field of iron-chromium redox flow battery, can solve the problems of area specific resistance, ion-exchange membrane cannot have chemical stability, etc., and achieve good performance of blocking iron and chromium ions , Improve the proton transmission ability, reduce the effect of resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

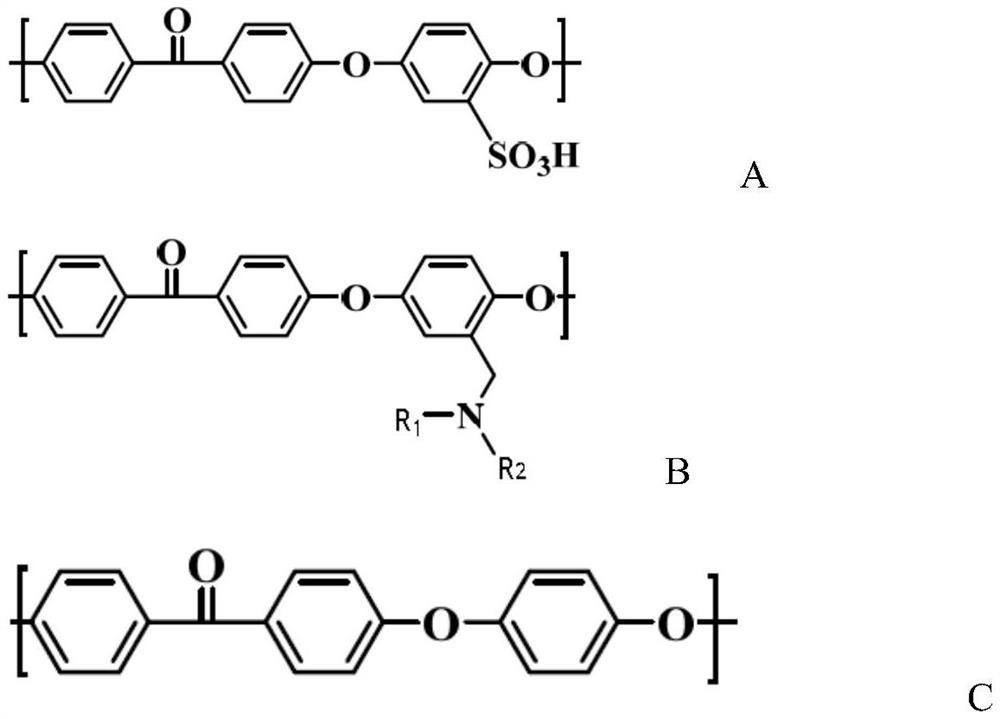

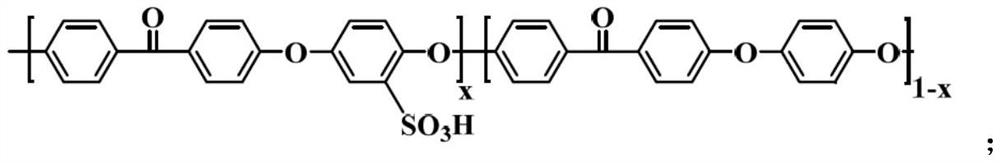

[0030] The second aspect of the present application also provides a method for preparing the above-mentioned amphoteric polyether ether ketone organic compound. The preparation method of the amphoteric polyether ether ketone organic compound comprises: in the presence of water and an alcohol solvent, sulfonated polyether ether ketone Amination reaction with organic amine and formaldehyde to obtain amphoteric polyetheretherketone organic compound containing both sulfonic acid groups and amino groups, wherein the sulfonated polyether ether ketone has the following structure:

[0031]

[0032] Organic amines have the structure R 1 R 2 NH, where R 1 and R 2 and x have the same definition as above, and the degree of polymerization of the sulfonated polyether ether ketone and the amphoteric polyether ether ketone organic compound to be prepared should correspond.

[0033] Compared with the existing synthesis route of amphoteric polyetheretherketone, the preparation method prov...

Embodiment 1

[0053] In this example, the preparation method of the amphoteric polyether ether ketone ion exchange membrane for the iron-chromium redox flow battery is as follows:

[0054] (1) Sulfonation reaction:

[0055] Dissolve 10 g of polyetheretherketone (molecular weight: 20,000 to 30,000) in 100 mL of concentrated sulfuric acid, and raise the temperature to 60° C. for sulfonation for 1.5 h. After the reaction was completed, the temperature of the reaction solution was lowered to 0° C., and then slowly poured into deiced water to precipitate precipitates, which were collected by filtration and washed with ice water for several times. After suction filtration, it was dried in a vacuum oven at 60° C. for 24 hours to obtain sulfonated polyetheretherketone with a sulfonation degree of 68%, with a yield of 90-95%.

[0056] (2) Amination reaction:

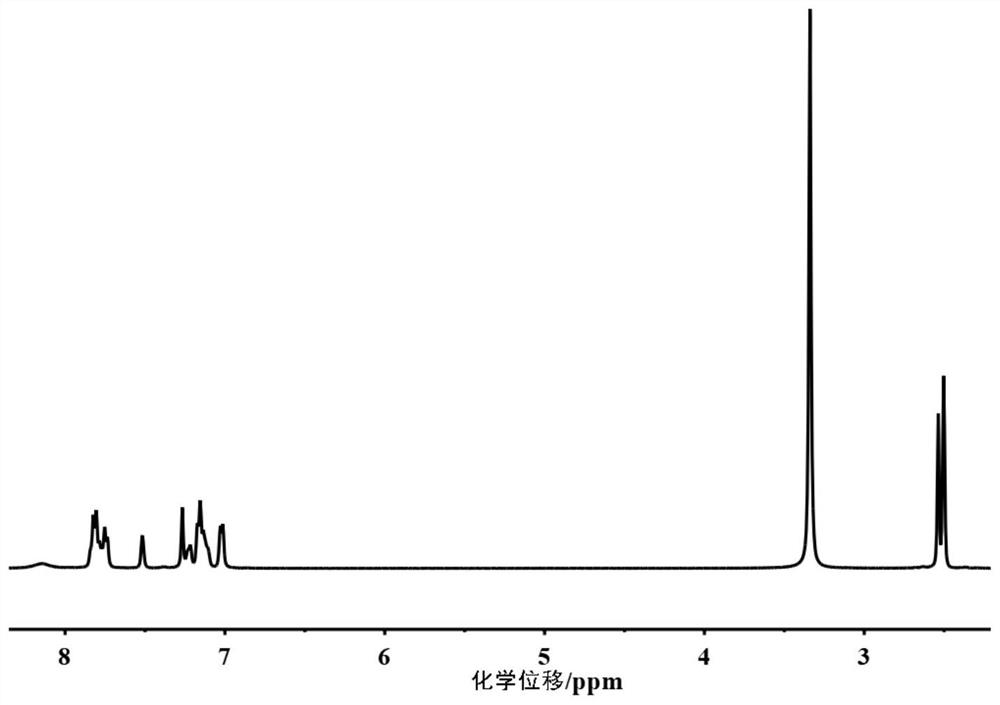

[0057] At room temperature, mix 10 g of the above sulfonated polyetheretherketone with 140 ml of water and 60 ml of ethanol, then add 10 ti...

Embodiment 2

[0066] In this example, the preparation method of the amphoteric polyether ether ketone ion exchange membrane for the iron-chromium redox flow battery is as follows:

[0067] (1) Sulfonation reaction:

[0068]Dissolve 10 g of polyether ether ketone in 100 ml of concentrated sulfuric acid, and raise the temperature to 60° C. for sulfonation reaction for 2 hours. After the reaction was completed, the temperature of the reaction solution was lowered to 0° C., and then slowly poured into deiced water to precipitate precipitates, which were collected by filtration and washed with ice water for several times. After suction filtration, it was dried in a vacuum oven at 60° C. for 24 hours to obtain sulfonated polyetheretherketone with a sulfonation degree of 72%, with a yield of 90-95%.

[0069] (2) Amination reaction:

[0070] The specific steps are the same as in Example 1. Amphoteric polyetheretherketone with a sulfonation degree of 72% and an amination degree of 5% is obtained t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com