Sulfur/sulfide/copper ternary composite cathode and preparation and application thereof in magnesium-sulfur battery

A ternary compound, sulfide technology, applied in the direction of positive electrode, battery electrode, secondary battery, etc., can solve the problem of reducing the polarization potential of battery charging, and achieve high rate performance, high Coulomb efficiency, and good capacity retention rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Weigh 1.0 g of tin disulfide with an electronic balance, and then weigh 2.0 g-8.0 g of sublimated sulfur powder and place it in an agate ball mill jar filled with 10 mL of ethanol for ball milling for 8 h (preferably 4.0 g of sublimated sulfur). Volatilize and remove to obtain sulfur / tin disulfide composite material. Place the dried sulfur / tin disulfide in a closed stainless steel-lined reactor at 150-160 °C for 12-36 h (preferably 155 °C, 24 h).

[0028] The sulfur / tin disulfide composite material, super P carbon black, and polyacrylic acid (PAA) were weighed at a mass ratio of 80:10:10 to prepare a uniformly dispersed slurry by grinding, and coated with copper foil and dried to obtain the positive electrode. piece.

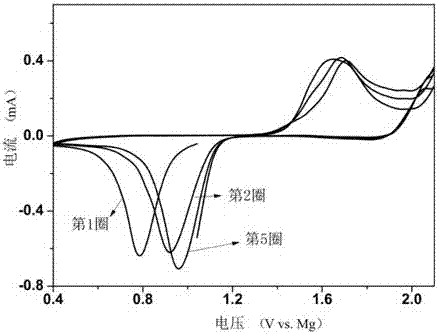

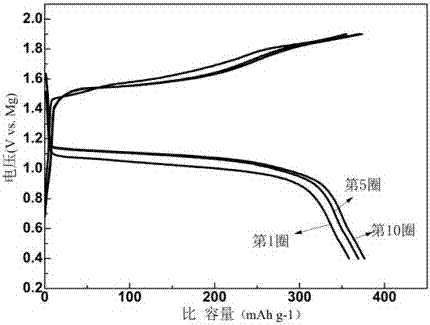

[0029] In a glove box filled with argon gas, the pole piece was used as the positive pole piece of the assembled battery, the magnesium piece was used as the negative pole piece, 0.05mol / L magnesium fluoride and 0.2 mol / L tris(hexafluoroisopropyl) borate...

Embodiment 2

[0031]Weigh 1.0 g of tin disulfide by electronic balance and place it in a beaker filled with 50 mL of deionized water and 10 mL of ethanol to obtain A by ultrasonication. Weigh 2.0g-8.0g of sublimated sulfur powder and place it in a beaker filled with 50mL of ethylenediamine to obtain B by ultrasonication. Slowly add A to B and add acid to adjust the pH to neutral or slightly acidic. Filter and dry to obtain sulfur / tin disulfide composite material. Preferably the sublimed sulfur is 4.0 g.

[0032] The sulfur / tin disulfide composite material, super P carbon black, and polyacrylic acid (PAA) were weighed at a mass ratio of 80:10:10 to prepare a uniformly dispersed slurry by grinding, and coated with copper foil and dried to obtain the positive electrode. piece.

[0033] In a glove box filled with argon gas, the pole piece was used as the positive pole piece of the assembled battery, the magnesium piece was used as the negative pole piece, 0.05mol / L magnesium fluoride and 0.2...

Embodiment 3

[0039] Weigh 1.0 g of iron disulfide with an electronic balance, and then weigh 2.0 g-8.0 g of sublimed sulfur powder and place it in an agate ball mill jar filled with 10 mL of ethanol for ball milling for 8 h (preferably 4.0 g of sublimed sulfur). Volatilize and remove to obtain sulfur / iron disulfide composite material. Place the dried sulfur / iron disulfide in a closed stainless steel-lined reactor at 150-160 °C for 12-36 h (preferably 155 °C, 24 h).

[0040] The sulfur / iron disulfide composite material, Super P carbon black, and polyacrylic acid (PAA) were weighed at a mass ratio of 80:10:10 to prepare a uniformly dispersed slurry by grinding, and coated with copper foil and dried to obtain the positive electrode. piece.

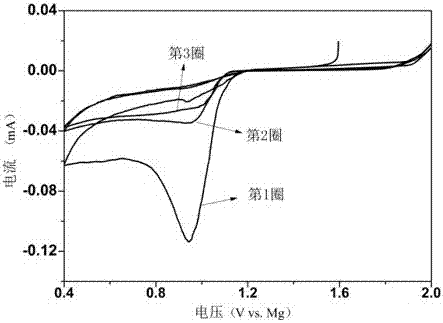

[0041] In a glove box filled with argon gas, the pole piece was used as the positive pole piece of the assembled battery, the magnesium piece was used as the negative pole piece, 0.05mol / L magnesium fluoride and 0.2 mol / L tris(hexafluoroisopropyl) borate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com