High-nickel ternary lithium-ion positive electrode material and preparation method thereof

A cathode material and lithium-ion technology, applied in the field of high-nickel ternary lithium-ion cathode materials and their preparation, can solve the problems of poor high-rate performance and poor cycle stability, and achieve excellent electrochemical performance, improved capacity, and cycle performance and the effect of rate performance optimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

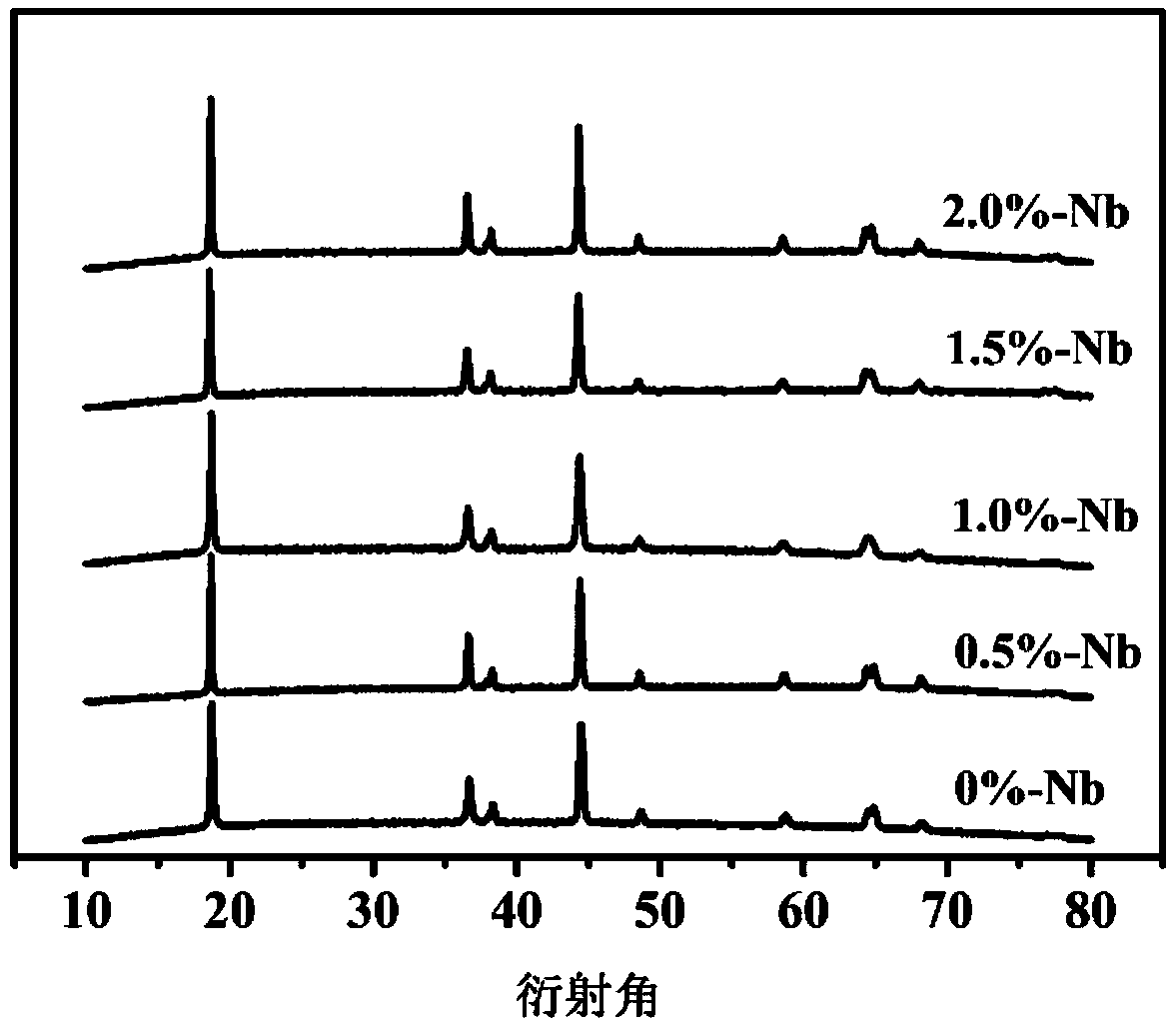

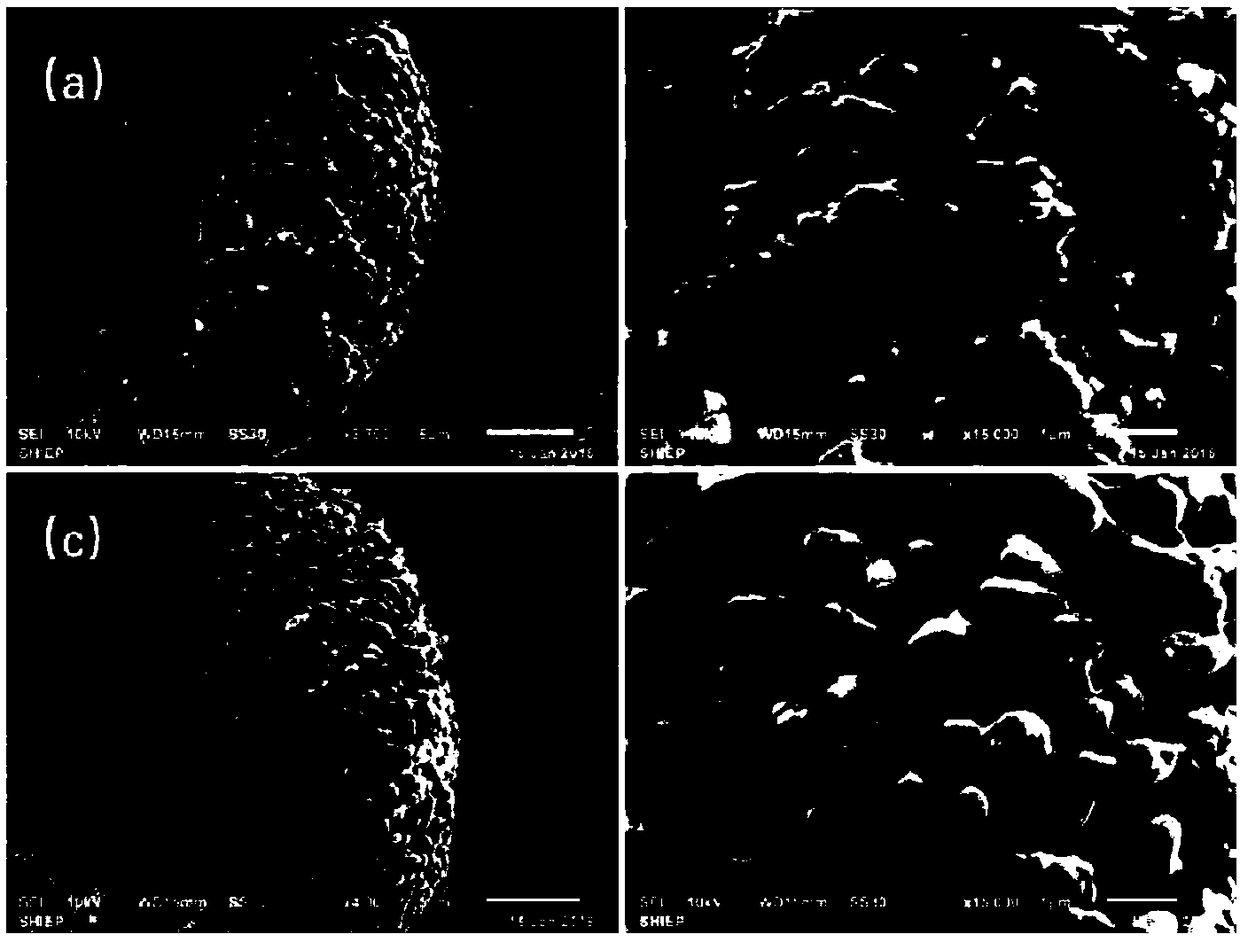

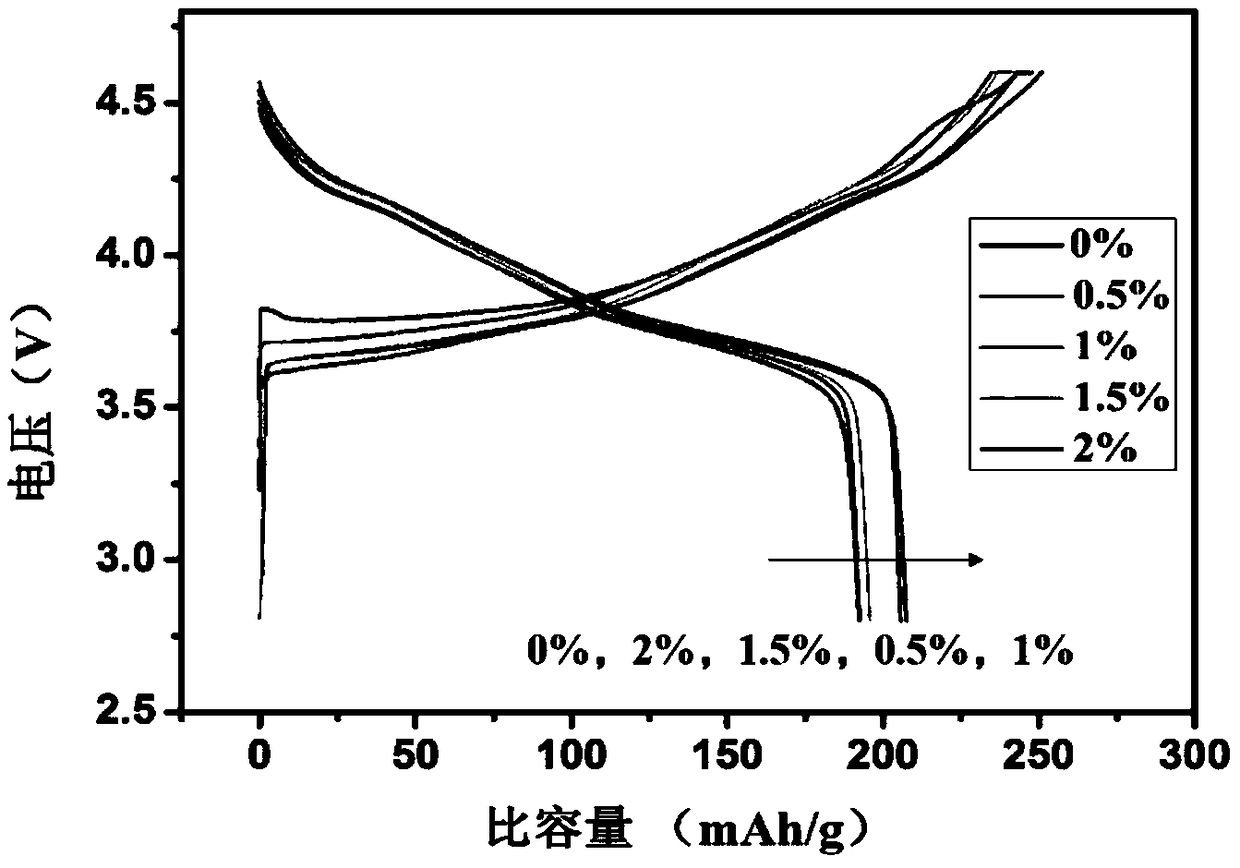

[0035] A pure-phase lithium-ion battery ternary cathode material whose chemical formula is LiNi 0.8 co 0.1 mn 0.1 o 2 , the specific steps of the preparation process are as follows:

[0036] 1) Precursor (chemical formula Ni 0.8 co 0.1 mn 0.1 CO 3 )A step of:

[0037] Weigh 2.32914g nickel acetate tetrahydrate, 0.29142g cobalt acetate tetrahydrate, 0.28676g manganese acetate tetrahydrate and 2.45946g urea and mix them in a beaker, add 40ml deionized water and stir until completely dissolved, then transfer to a 100ml polytetrafluoroethylene reactor place in a blast drying oven at 200°C for 10 hours, after the heat preservation is over, let it cool down to room temperature naturally, filter and wash the solution and precipitate in the reaction kettle until the pH of the filtrate is less than 7.5, and the color of the filtrate changes from blue to no color, a light green precipitate was obtained.

[0038] 2) Preparation of LiNi by high temperature solid phase method 0.8...

Embodiment 2

[0041] A kind of lithium ion battery ternary cathode material, its chemical formula is Li(Ni 0.8 co 0.1 mn 0.1 ) 0.99 Nb 0.01 o 2 , the specific steps of its preparation process are as follows:

[0042] 1) Precursor prepared by hydrothermal method (chemical formula (Ni 0.8 co 0.1 mn 0.1 ) 0.99 Nb 0.01 CO 3 )A step of:

[0043] Weigh 2.30585g nickel acetate tetrahydrate, 0.28851g cobalt acetate tetrahydrate, 0.2839g manganese acetate tetrahydrate, 0.06295g niobium oxalate hydrate and 2.45946g urea in a beaker, add 40ml deionized water and stir until completely dissolved, transfer to 100ml Put it in a polytetrafluoroethylene reaction kettle, and place it in a blast drying oven at 200°C for 10 hours. After the heat preservation is over, let it cool down to room temperature naturally. Filter and wash the solution and precipitate in the reaction kettle until the pH of the filtrate is less than 7.5, and the color of the filtrate is From blue to colorless, a light green p...

Embodiment 3

[0047] A kind of lithium ion battery ternary cathode material, its chemical formula is Li(Ni 0.8 co 0.1 mn 0.1 ) 0.995 Nb 0.005 o 2 , the specific steps of its preparation process are as follows:

[0048] 1) Precursor prepared by hydrothermal method (chemical formula (Ni 0.8 co 0.1 mn 0.1 ) 0.995 Nb 0.005 CO 3 )A step of:

[0049] Weigh 2.31749g nickel acetate tetrahydrate, 0.28996g cobalt acetate tetrahydrate, 0.28533g manganese acetate tetrahydrate, 0.03148g niobium oxalate hydrate and 2.45946g urea in a beaker, add 40ml deionized water and stir until completely dissolved, transfer to 100ml Put it in a polytetrafluoroethylene reaction kettle, and place it in a blast drying oven at 200°C for 10 hours. After the heat preservation is over, let it cool down to room temperature naturally. Filter and wash the solution and precipitate in the reaction kettle until the pH of the filtrate is less than 7.5, and the color of the filtrate is From blue to colorless, a light gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com