Composite membrane, preparation method of composite membrane, and lithium-ion battery

A technology of composite diaphragm and mixture, which is applied in the direction of composite electrolyte, secondary battery, battery pack components, etc., can solve the problems that it is difficult to improve the charge-discharge cycle performance of lithium-ion batteries with gel polymer electrolyte membranes, and achieve good electrochemical performance. Effects of cycle performance and capacity retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0016] The embodiment of the present invention provides a preparation method of a composite diaphragm, which comprises the following steps:

[0017] S1, preparing a solution with a nano-sol, the nano-sol is selected from at least one of titanium sol, aluminum sol, silica sol and zirconium sol, the nano-sol contains a MOH group, and M in the MOH group is titanium, aluminum, silicon or zirconium;

[0018] S2, adding a silane coupling agent containing a C=C group and methyl methacrylate (MMA) to the solution, and uniformly mixing to form a first mixture;

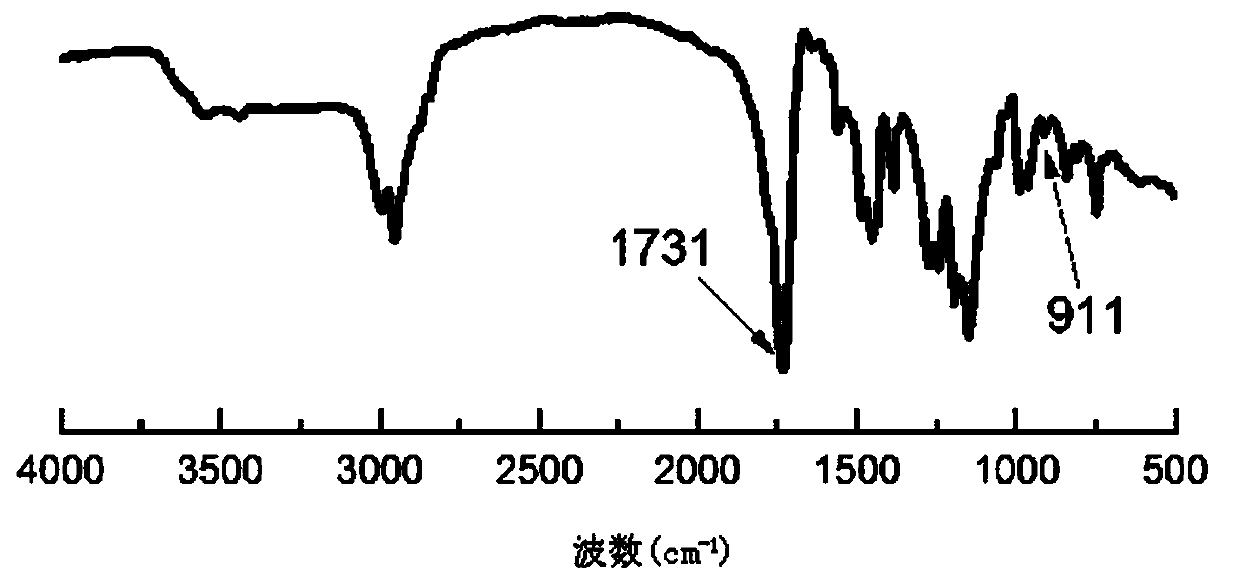

[0019] S3, add initiator in this mixture and make MMA and this silane coupling agent polymerize, form polymer, and make this silane coupling agent and this nano-sol take place condensation reaction while polymerizing, thereby this nano-sol is connected on PMMA On the substrate, an inorganic-organic graft hybrid polymer is formed;

[0020] S4, mixing the inorganic-organic graft hybrid polymer with PVDF-HFP in an organic solven...

Embodiment 1

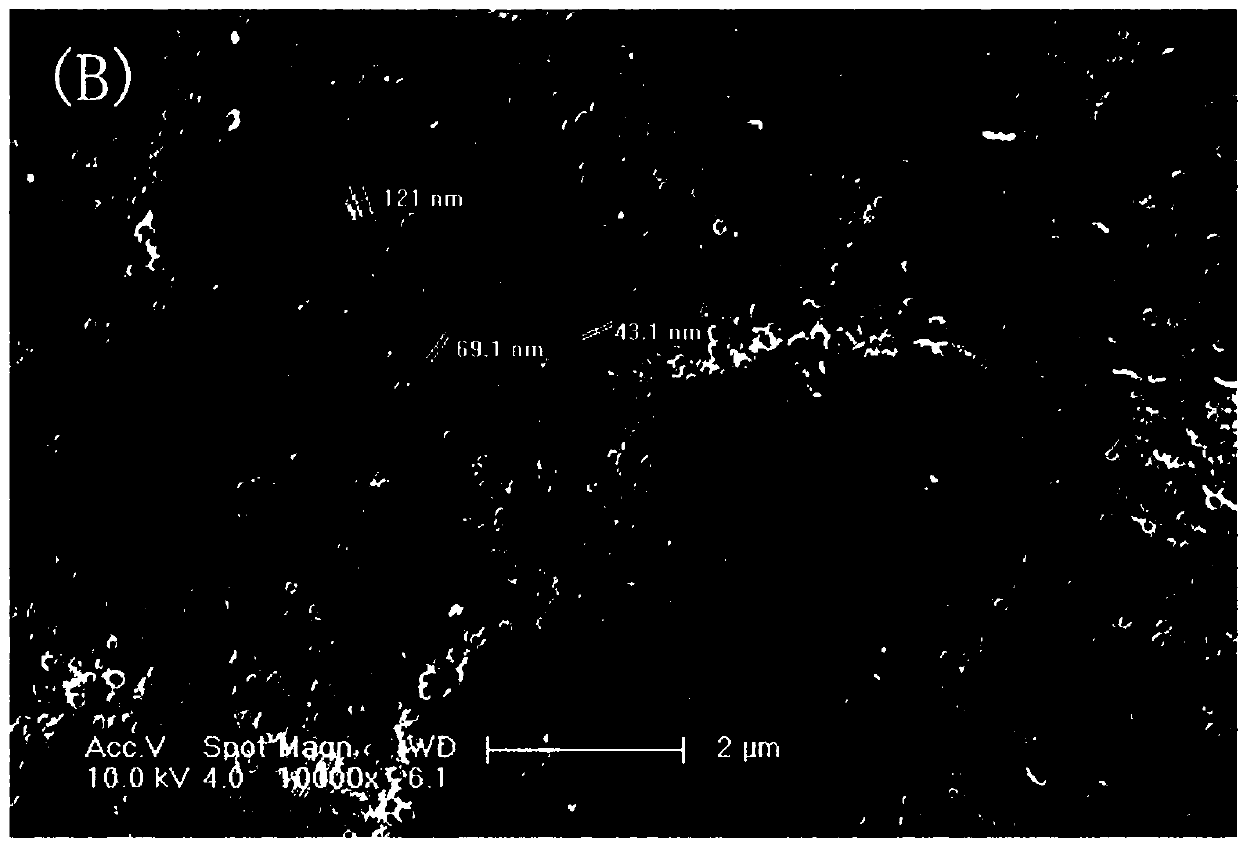

[0051] Mix 10 mL of tetrabutyl titanate with 50 mL of ethanol to form a first solution. Mix deionized water and 50 mL ethanol to form a second solution, and add nitric acid to the second solution to make the pH value 3-4. The molar ratio of deionized water to tetrabutyl titanate is 4:1. The first solution was mixed with the second solution and heated at 65° C. to form a titanium sol solution. The titanium sol solution was heated to 80° C., vinyltrimethoxysilane and MMA monomer were added to the titanium sol solution, and uniformly mixed by stirring to form a first mixture. An initiator, benzoyl peroxide, is added to the first mixture to polymerize MMA and vinyltrimethoxysilane to form the inorganic-organic graft hybrid polymer.

[0052] PVDF-HFP containing 10% inorganic-organic grafted hybrid polymer was dissolved in DMF to form a clear solution with a concentration of 15%. Then the solution was coated on both surfaces of the PE diaphragm, and then the coated diaphragm was ...

Embodiment 2

[0056] The difference from Example 1 is only that tetrabutyl titanate is replaced by aluminum isopropoxide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com