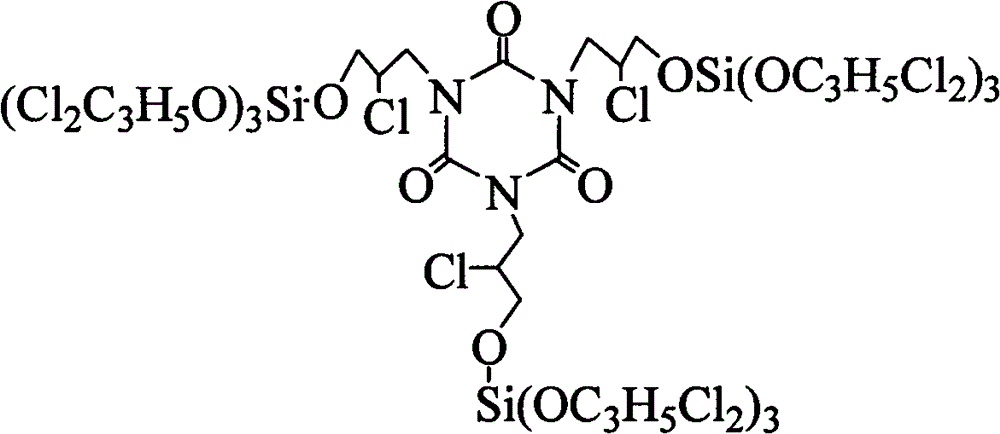

Triazine chlorotrisilicate compound and preparation method thereof

A technology of trisilicate and triazine chloride, applied in the direction of silicon organic compounds, etc., can solve the problems of high price, narrow scope of use, restrictions, etc., and achieve the effects of low cost, good environmental benefits, and good symmetry characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

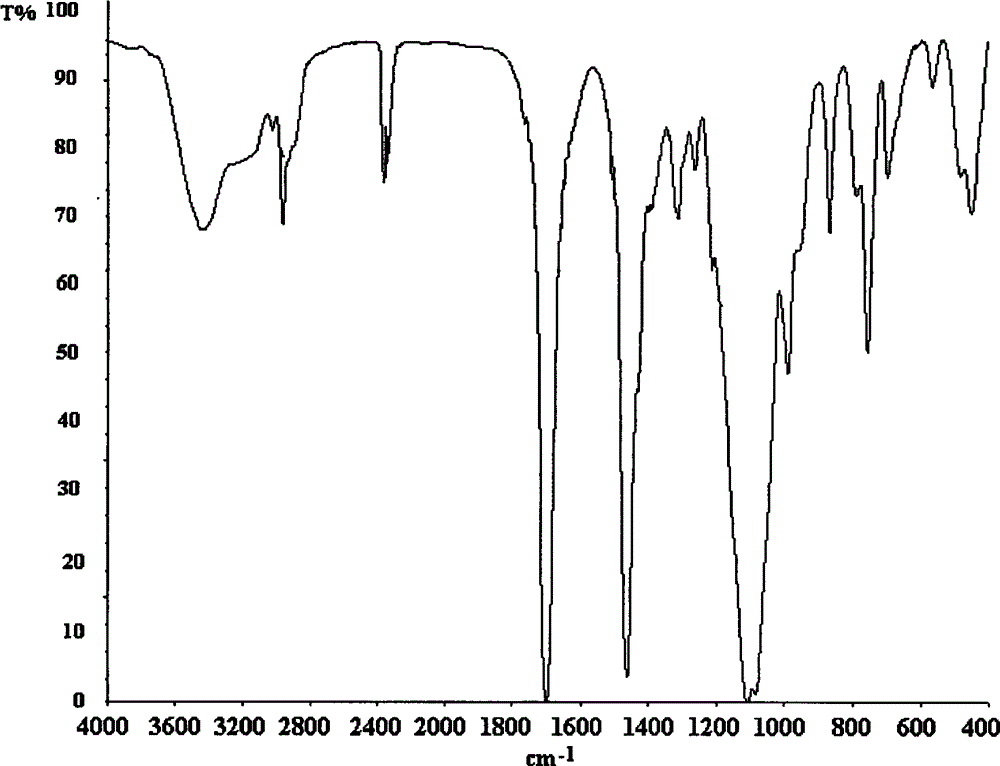

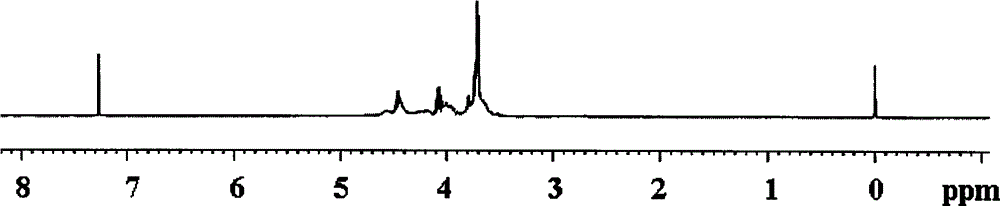

Image

Examples

Embodiment 1

[0028] Example 1 Add 10ml of acetonitrile and 3.40ml (0.03mol) of silicon tetrachloride to a 100ml four-necked reaction flask equipped with a stirrer, a thermometer, and a high-efficiency reflux condenser, and add 3.00g (0.01mol) of isochloride dropwise at 25°C. 50ml of acetonitrile solution of triglycidyl cyanurate, the temperature of the system should not exceed 30°C at the rate of addition, after the drop, the temperature will rise to 60°C within 1 hour, keep the temperature for 4 hours, then lower the temperature of the system to 40°C, add 8.33g dropwise (0.09mol) 2,3-dichloropropanol, after dripping, heat up to 50°C, keep warm for 6 hours, add about 0.5g triethanolamine dropwise, adjust to PH=5-6, stir for 1 hour, filter, and distill out the filtrate Organic solvent (recycling), then distill off excess 2,3-dichloropropanol (recycling) and a small amount of low boiling point under reduced pressure to obtain a colorless or light yellow liquid tri{2-chloro-3-[three ( 2,3-Dic...

Embodiment 2

[0029]Example 2 Add 10ml of dichloroethane, 3.40ml (0.03mol) of silicon tetrachloride in a 100ml four-necked reaction flask equipped with a stirrer, a thermometer, and a high-efficiency reflux condenser, and add 3.00g (0.01mol) of silicon tetrachloride dropwise at 25°C. mol) dichloroethane solution of triglycidyl isocyanurate 50ml, control the temperature of the system to not exceed 30°C at the rate of addition, after the drop is completed, heat up to 60°C within 1 hour, keep the temperature for 5 hours, and then lower the temperature of the system to 40°C ℃, add 9.25 (0.10mol) 2,3-dichloropropanol dropwise, after dropping, raise the temperature to 60°C, keep warm for 6 hours, add about 0.5g N,N-dimethylaniline dropwise, adjust to PH=5 -6, stirred for 1h, filtered, the filtrate was distilled to remove the organic solvent (for recycling), and then distilled off excess 2,3-dichloropropanol (for recycling) and a small amount of low boiling point matter under reduced pressure to ob...

Embodiment 3

[0030] Example 3 Add 10ml of tetrachloroethane, 3.40ml (0.03mol) of silicon tetrachloride in a 100ml four-necked reaction flask equipped with a stirrer, a thermometer, and a high-efficiency reflux condenser, and add 3.00g (0.01mol) of silicon tetrachloride dropwise at 25°C. mol) 50ml of tetrachloroethane solution of triglycidyl isocyanurate, control the system temperature not to exceed 30°C at the rate of addition, after the drop is completed, heat up to 60°C within 1 hour, keep the temperature for 5 hours, and then lower the system temperature to 40°C ℃, add 10.18g (0.11mol) dichloropropanol dropwise, after dropping, raise the temperature to 70°C, keep warm for 5h, add about 0.5g pyridine dropwise, adjust to PH=5-6, stir for 1h, filter, and distill the filtrate Remove the organic solvent (for recycling), then distill off excess 2,3-dichloropropanol (for recycling) and a small amount of low boiling point substances under reduced pressure to obtain a colorless or pale yellow liq...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

| decomposition temperature | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com