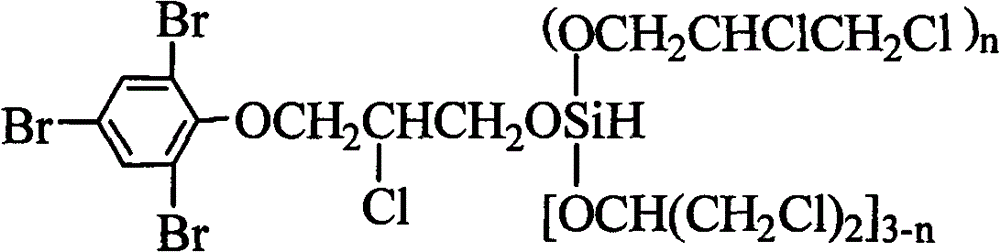

Tribromophenoxychloropropoxytri(dichloropropyl)silicate compound and preparation method thereof

A technology of tribromophenoxychloropropoxysilicate tris and bromophenoxychloropropoxysilicate tris, which is applied in the field of tribromophenoxychloropropoxysilicate triester compounds and their preparation, It can solve the problems of narrow application range and high price, and achieve the effect of low cost, cheap raw materials and stable physical and chemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

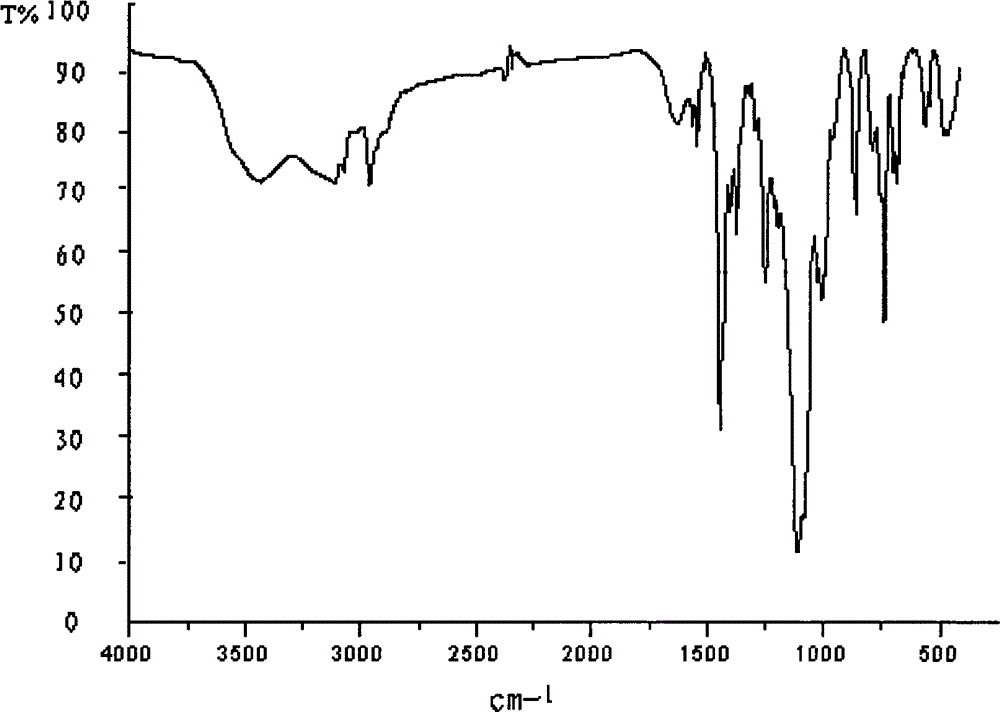

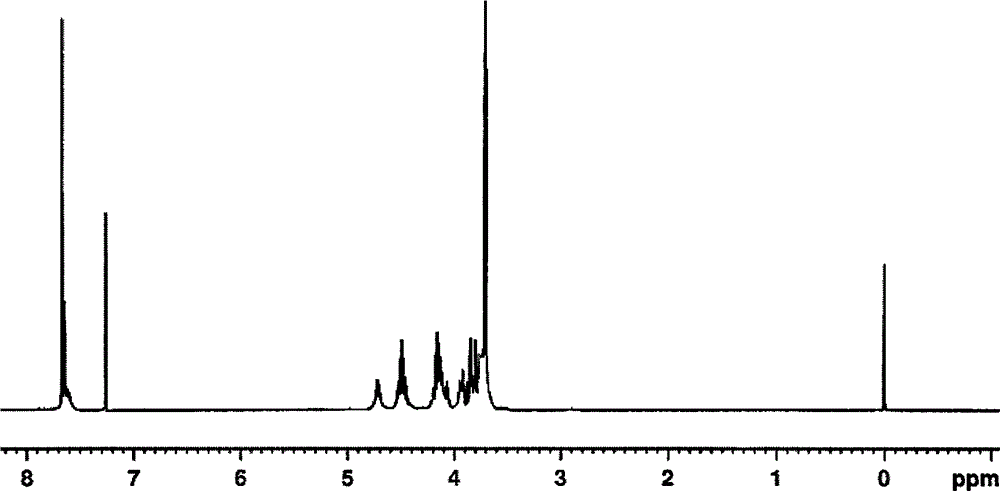

[0027] Example 1 In a 100ml four-neck flask equipped with a stirrer, a thermometer, and a high-efficiency reflux condenser, add 10ml of acetonitrile, 5.1g (0.03mol, 3.4ml) of silicon tetrachloride, and drop 50ml of it within 60min at 20°C. A solution of 11.6g (0.03mol) tribromophenylglycidyl ether dissolved in acetonitrile, the dropwise addition process controls the temperature not to exceed 35°C, after the dropwise addition, the temperature is raised to 60°C within 1h, kept for 6h, and then added dropwise within 1h Epichlorohydrin 8.4g (0.09mol), after dripping, keep warm at 70°C for 10h, the pH value of the reaction system reaches 5-6, after the reaction is completed, acetonitrile is removed by distillation under reduced pressure (recycled), and bromophenoxy is obtained as a light yellow liquid Chloropropoxy tris(dichloropropyl)silicate, product yield 94.7%. Its flash point (open cup): 228±5°C, decomposition temperature: 302±5°C, density (25°C): 1.857g / cm 3 , Refractive ind...

Embodiment 2

[0028] Example 2 In a 100ml four-neck flask equipped with a stirrer, a thermometer, and a high-efficiency reflux condenser, add 10ml of dichloroethane, 5.1g (0.03mol, 3.4ml) of silicon tetrachloride, and drop it in 60min at 20°C Add a solution of 11.6g (0.03mol) tribromophenylglycidyl ether dissolved in 50ml dichloroethane, and control the temperature during the dropwise addition to not exceed 35°C. After the dropwise addition, raise the temperature to 60°C within 1h and keep it warm for 5h , then 9.16g (0.099mol) of epichlorohydrin was added dropwise within 1 hour, and after the drop was completed, the temperature was kept at 80°C for 9 hours, and the pH value of the reaction system reached 5-6. Epichlorohydrin (recycled for use) and a small amount of low-boilers were used to obtain tris(dichloropropyl)bromophenoxychloropropoxysilicate as a pale yellow liquid, and the product yield was 95.8%. Its flash point (open cup): 228±5°C, decomposition temperature: 302±5°C, density (25...

Embodiment 3

[0029] Example 3 In a 100ml four-necked flask equipped with a stirrer, a thermometer, and a high-efficiency reflux condenser, add 10ml of dichloroethane, 5.1g (0.03mol, 3.4ml) of silicon tetrachloride, and drop it in 60min at 20°C Add a solution of 11.6g (0.03mol) tribromophenylglycidyl ether dissolved in 50ml of dichloroethane, and control the temperature during the dropwise addition to not exceed 35°C. After the dropwise addition, the temperature will be raised to 70°C within 1h and kept for 4h , then 9.99 g (0.108 mol) of epichlorohydrin was added dropwise within 1 h, and after the drop was completed, 80 ° C was incubated for 8 h, and the pH value of the reaction system reached 5-6. After the reaction was completed, dichloroethane and excess Epichlorohydrin (recycled for use) and a small amount of low-boilers were used to obtain tris(dichloropropyl)bromophenoxychloropropoxysilicate, a light yellow liquid, with a yield of 97.6%. Its flash point (open cup): 228±5°C, decomposi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition temperature | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com