Treating method for high magnesium laterite nickel mine

A lateritic nickel ore and treatment method technology, applied in the field of metallurgy, can solve the problems of low leaching rate of nickel and cobalt metals, less demand for final product application, equipment corrosion, etc., achieve high-efficiency extraction, easy liquid-solid separation, and low production cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

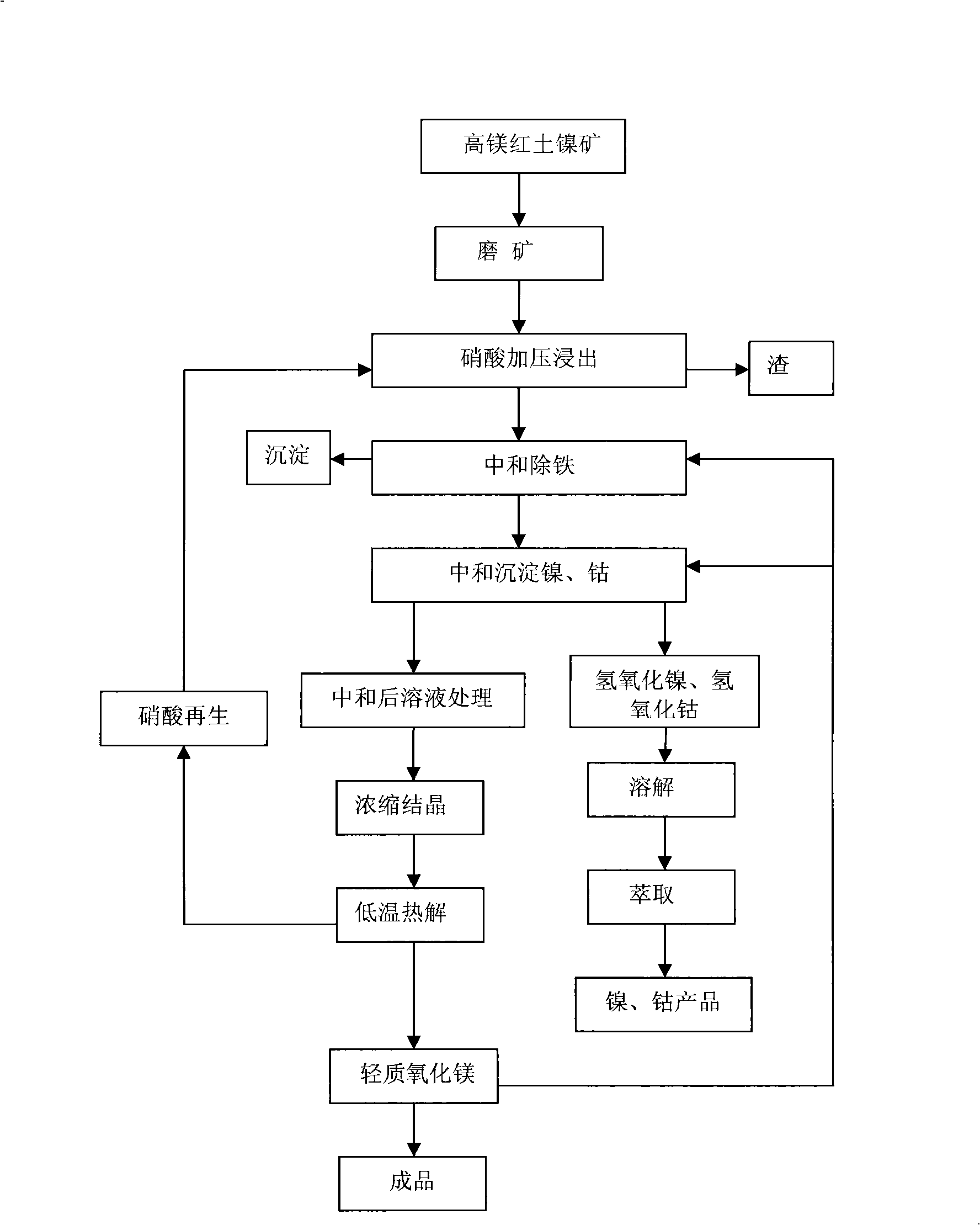

[0031] This embodiment provides a method for processing high-magnesium laterite nickel ore, mainly using nitric acid as the leaching medium, and leaching the high-magnesium laterite nickel ore in the nitric acid medium by a pressure acid leaching method. The processing flow of the method is as follows figure 1 As shown, it specifically includes the following steps:

[0032] (1) Pretreatment: crush and grind the high-magnesium laterite nickel ore. After treatment, the proportion of mineral particles with a particle size of less than 75μm in the total mineral material is not less than 80%, and generally accounts for 85% to 98%. Can

[0033](2) Pressure leaching: Using nitric acid as the leaching medium, the pretreated mineral material is mixed with the corresponding concentration of nitric acid solution according to a certain liquid-solid ratio, and then heated, stirred, and pressure leached in the autoclave after mixing. When the set temperature is reached, oxygen is introduced; th...

Embodiment 2

[0039] This embodiment provides a method for processing high-magnesium laterite nickel ore, which specifically includes: the composition of the high-magnesium laterite nickel ore used is: nickel Ni 1.10%, cobalt Co 0.021%, iron Fe 9.94%, magnesium Mg 17.67%, and dioxide Silicon SiO 2 38.60%, aluminum Al 1.37%. The pressure leaching conditions are: crush and ball mill the mineral material of the high-magnesia laterite nickel ore. After treatment, the mineral material particles with a particle size of 75μm account for 90% of the total mineral material. Take 50 grams of the mineral material in a 2L autoclave Leaching, the amount of nitric acid is 1.20gHNO 3 / g ore, used in nitric acid solution, leaching temperature is 150℃, leaching time: 60min, ratio of nitric acid solution volume to mineral material mass is 8:1, oxygen partial pressure is 0.10MPa, stirring speed is 300rpm. Crystal thermal decomposition process conditions: decomposition temperature 500℃, decomposition time 60min. Le...

Embodiment 3

[0041] This embodiment provides a method for processing high-magnesium laterite nickel ore, which specifically includes: the used high-magnesium laterite nickel ore composition: nickel Ni 0.95%, cobalt Co 0.019%, iron Fe 10.00%, magnesium Mg 17.58%, silicon dioxide SiO 2 38.10%, aluminum Al 1.40%. Pressure leaching conditions: high-magnesia laterite nickel ore with a particle size of 75μm accounted for 93% of the total amount of minerals, 50g of the mineral sample was leached in a 2L autoclave, and the amount of nitric acid was 1.25gHNO 3 / g ore, leaching temperature 150℃, leaching time: 60min, liquid-solid ratio 5:1, oxygen partial pressure 0.10MPa, stirring speed 500rpm. Crystal thermal decomposition process conditions: decomposition temperature 500℃, decomposition time 30min. Leaching rate: nickel Ni 95.74%, cobalt Co 94.50%, magnesium Mg 98.96%, aluminum Al 90.72%, Fe 0.76g / L in the leaching solution. The solution after iron removal contains 0.029g / L of iron, and the solution ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com