Method for joint production of natural gas and liquid ammonia by using coke oven gas and blast-furnace gas

A technology for coke oven gas and blast furnace gas, which is applied in the field of comprehensive utilization of gas in iron and steel enterprises, can solve problems such as low calorific value, and achieve the effects of solving the problem of utilization, good economic and social benefits, and high economic added value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

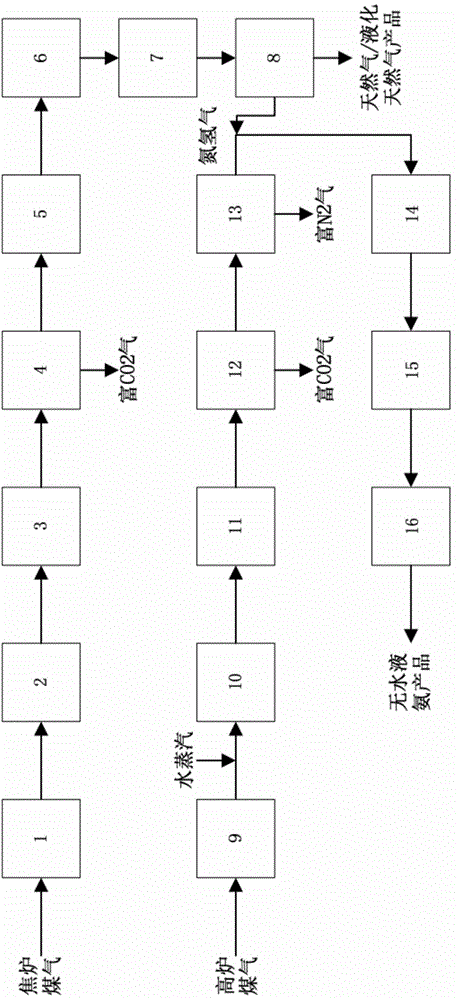

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments, but the methods provided are only examples and should not be construed as limiting the scope of the present invention.

[0030] Such as figure 1 As shown, the present invention utilizes coke oven gas and blast furnace gas to jointly produce the processing method of natural gas and liquefied ammonia, and concrete processing steps are as follows:

[0031] First, the purified coke oven gas in the coking plant is compressed and pressurized by Roots blower or screw compressor 1, then compressed to 0.1-1MPa by screw compressor, or compressed to 0.01-0.1MPa by Roots blower, and enters temperature swing adsorption device 2 , most of the sulfur, tar, benzene, naphthalene and other impurities in the coke oven gas are adsorbed on the adsorbent in the adsorption tower to remove them, and then pass through the first and second sections 3 of the 1# c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com