Method for producing plum juice via plum halogen desalination

A plum juice and extraction technology, which is applied in the field of preparing plum juice by desalting plum brine, and the preparation field of plum juice, can solve the problems of high salt content of plum brine, harm to the ecological environment, waste of resources, etc., and achieves stable and reliable process technology. The effect of strong operability and small investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

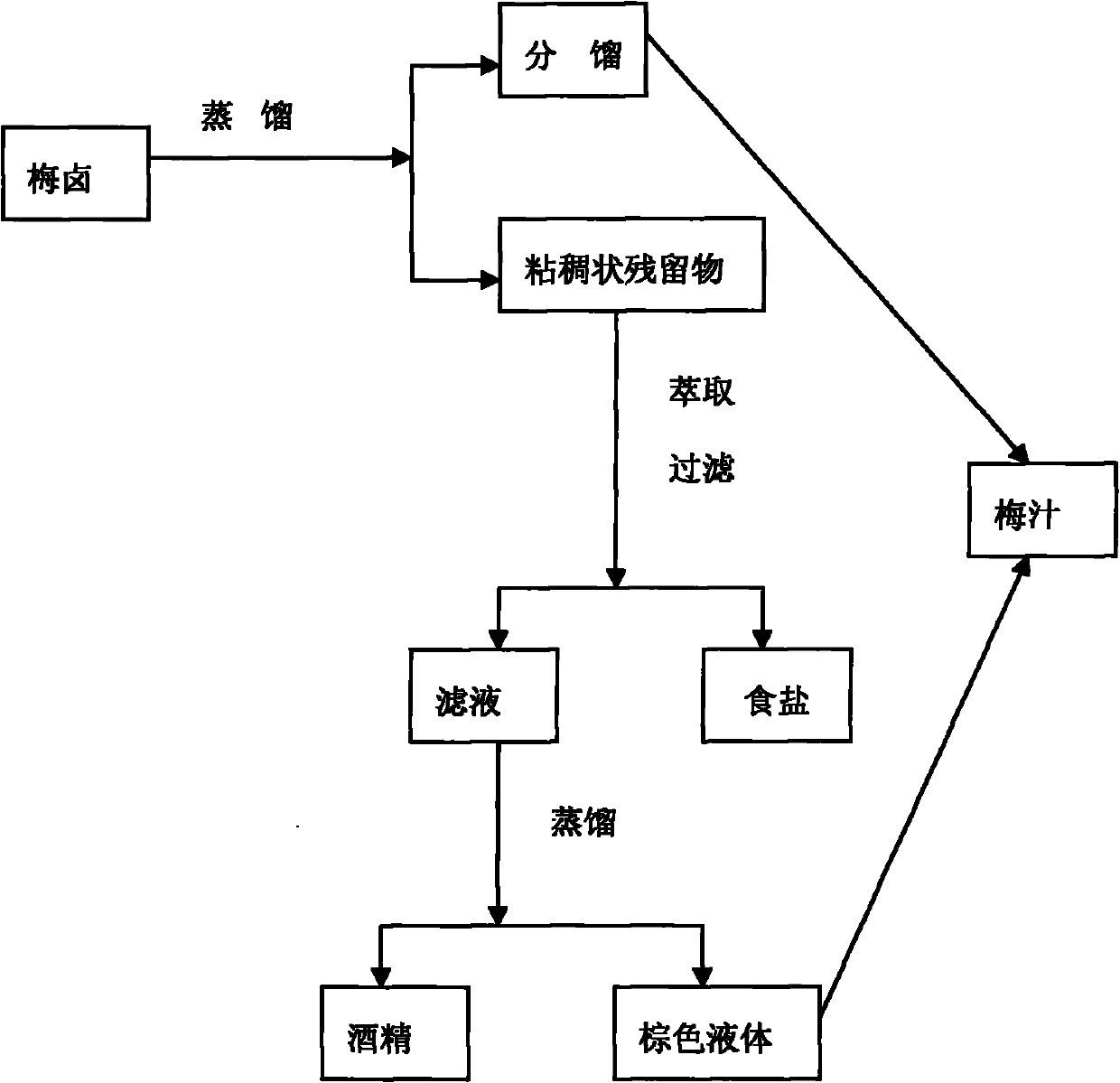

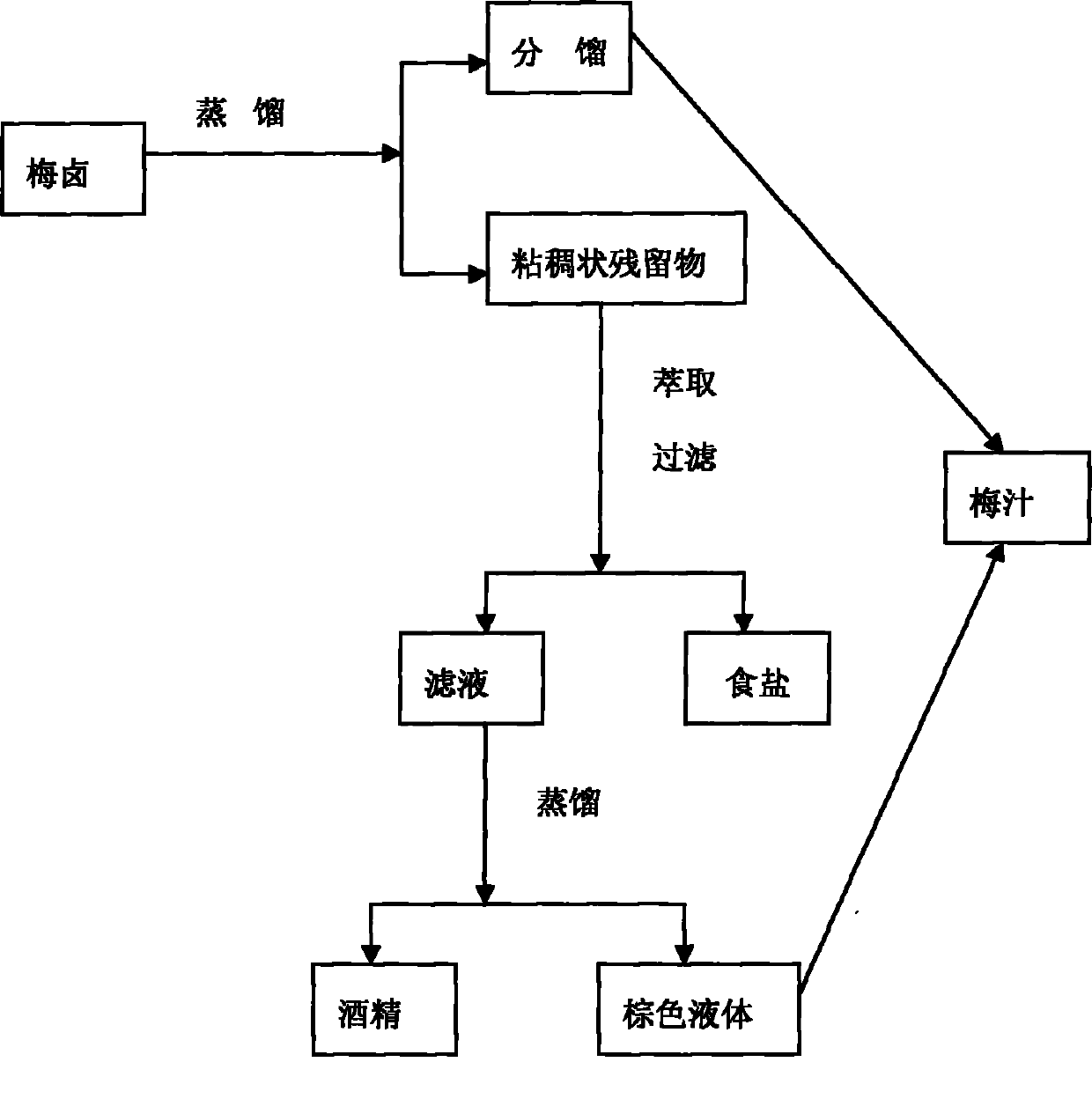

[0016] 1. Distill 100 liters of plum brine to a thick product under normal pressure with a conventional electric distillation device, fractionate 71 liters of distillate, add 25 liters of edible alcohol with a concentration of 95% to the remaining thick residue to obtain a mixture;

[0017] 2. Put the mixture obtained in step 1 into a conventional extractor, heat it to 40°C for 30 minutes, then cool it to 18°C, and filter it with cotton cloth to obtain 51 liters of filtrate and 22 kg of table salt;

[0018] 3. After distilling the filtrate obtained in step 2 with a conventional electric still, distill out 25 liters of alcohol and recover, remove the remaining liquid in the still, and filter to obtain 21 liters of brown liquid;

[0019] 4. Mix 71 liters of fractions obtained in step 1 with 21 liters of brown liquid obtained in step 3 to obtain about 90 liters of plum juice.

Embodiment 2

[0021] 1. Distill 1000 milliliters of plum brine to a thick substance under normal pressure with a conventional distiller, fractionate 730 milliliters, add 300 milliliters of edible alcohol with a concentration of 85% to the remaining thick residue to obtain a mixture;

[0022] 2. Put the mixture obtained in step 1 into a conventional extractor, heat to 50°C for extraction for 20 minutes, then cool to 20°C, and filter with cotton cloth to obtain 540 ml of filtrate and 108 grams of table salt;

[0023] 3. After distilling the filtrate obtained in step 2 with a conventional electric still, distill out 300 ml of alcohol and recover it, remove the remaining liquid in the still, and filter to obtain 210 ml of brown liquid;

[0024] 4. Mix 730 ml of fractions obtained in step 1 with 210 ml of brown liquid obtained in step 3 to obtain 940 ml of plum juice.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com