Method for producing L-arabinose

A kind of technology of arabinose and production method, which is applied in the production field of L-arabinose, can solve the problems of high efficiency, inability to directly produce xylose, inability to purify, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

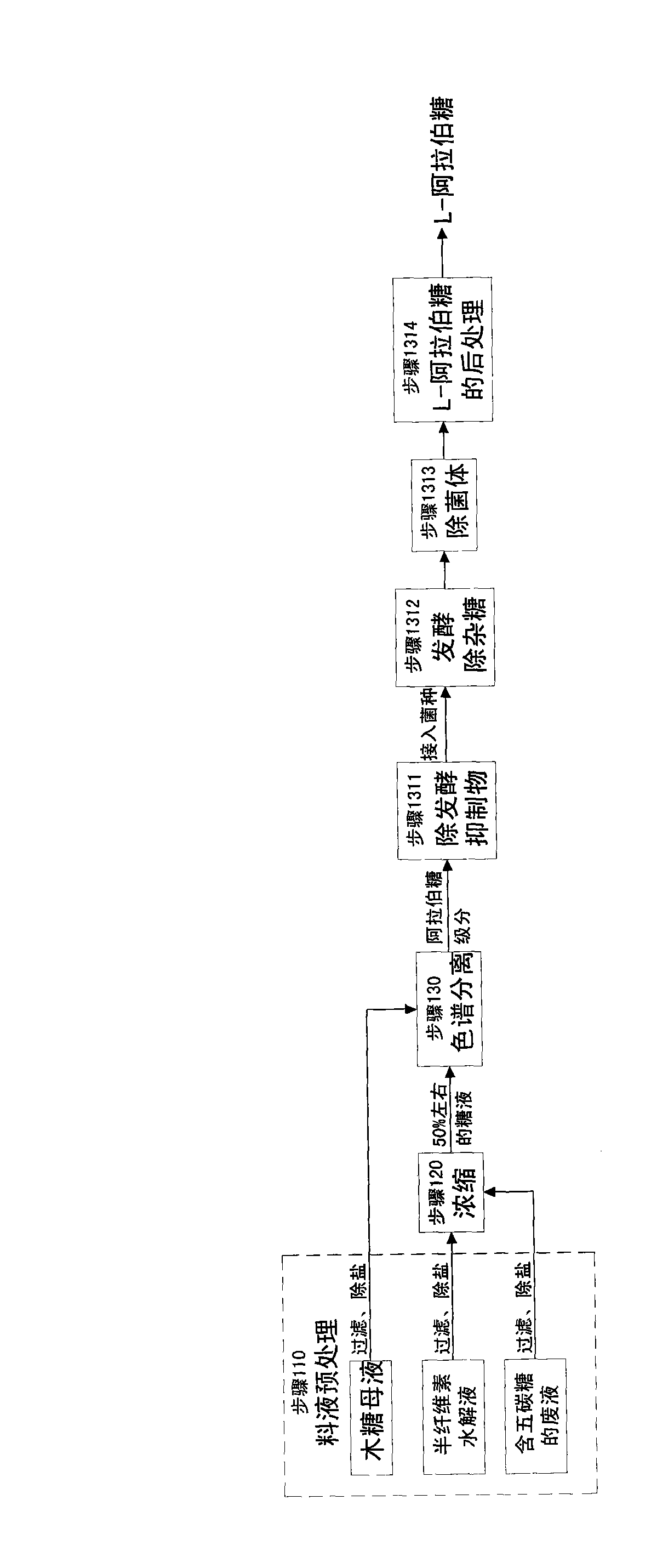

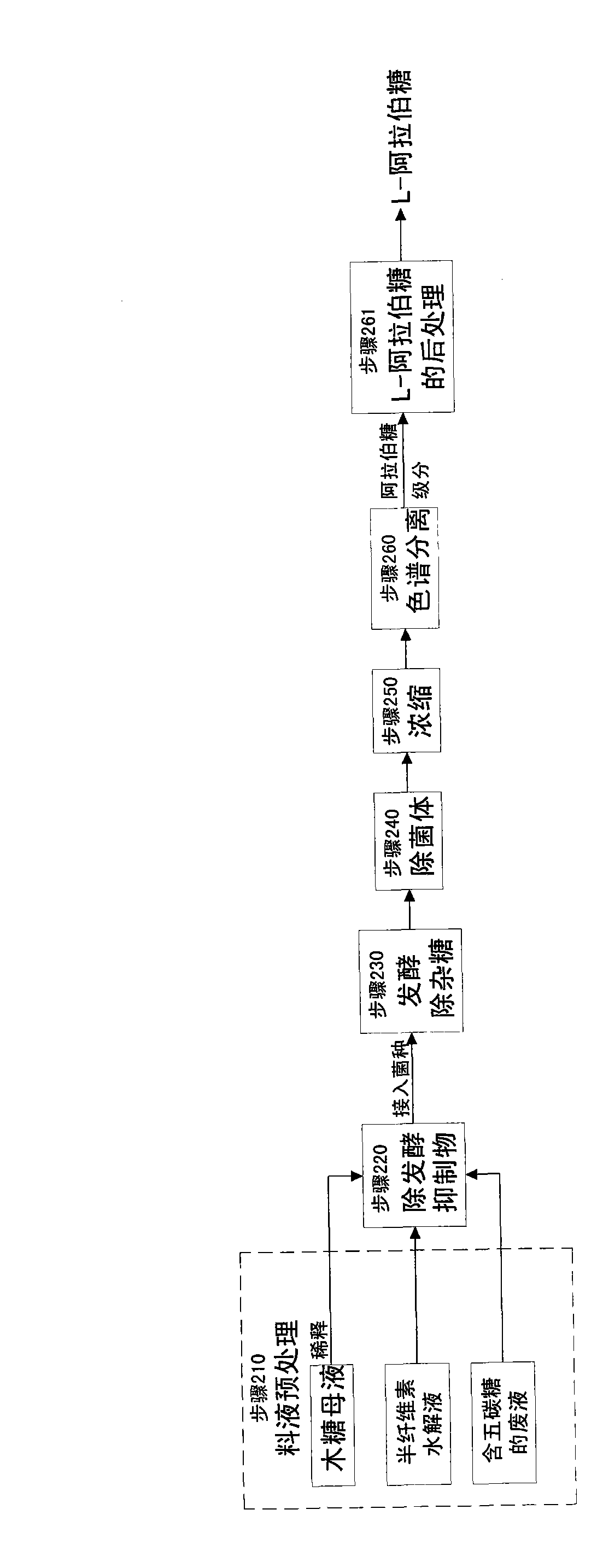

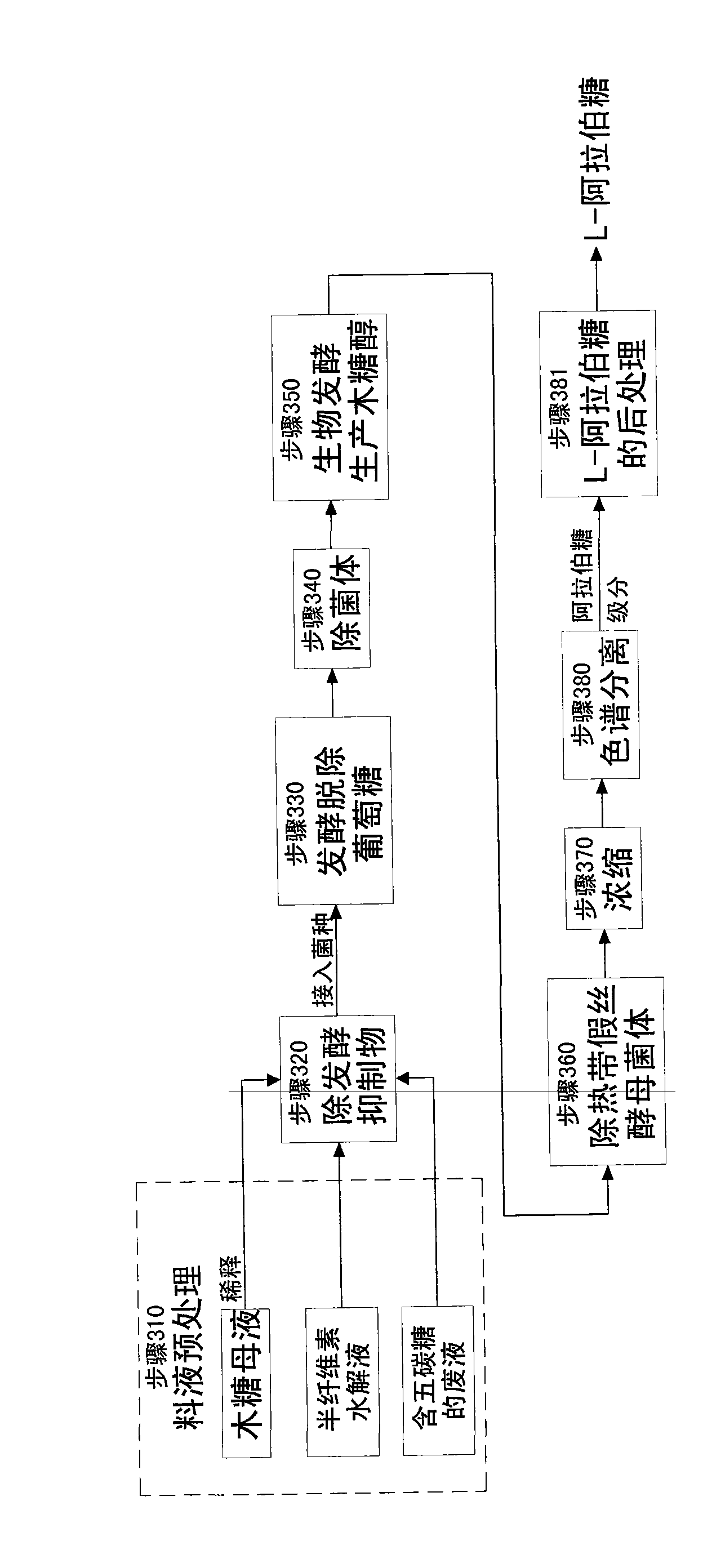

Method used

Image

Examples

example 1

[0188] Example 1 The specific process parameters for the arabinose fraction to use Saccharomyces cerevisiae to ferment glucose and galactose to produce ethanol under anaerobic conditions are as follows: the percentages are mass percentages.

[0189] (1) first adjust the sugar concentration of the arabinose solution to 10-40%, preferably 20-35%;

[0190] (2) The composition of the culture medium nutrient salt is: urea or ammonium sulfate: 0.01~0.5%, preferably 0.05~0.2%; Potassium dihydrogen phosphate: 0.01~0.5%, preferably 0.01~0.2%; Magnesium sulfate: 0.01~0.2% 0.4%, preferably 0.01-0.2%;

[0191] (3) The parameters of the fermentation process are: pH: 2.5~5, temperature 33~45°C, no air or a small amount of air (0.1~0.3vvm) at the beginning of fermentation, when the cell concentration reaches 10 8 / ml, the air was stopped and anaerobic fermentation was carried out.

[0192] (4) Technical indicators: glucose removal rate 97.15-98.5%, ethanol yield 98-99%, arabinose yield 9...

example 2

[0193] Example 2, The specific process parameters of the arabinose fraction using Saccharomyces cerevisiae to ferment under aerobic conditions to remove glucose and galactose to generate ethanol, carbon dioxide and water are as follows: the percentages are mass percentages.

[0194] (1) first adjust the sugar concentration of the arabinose solution to 8-30%, preferably 10-25%;

[0195] (2) The composition of the culture medium nutrient salt is: ammonium sulfate: 0.1~3.5%, preferably 0.5~2.5%; potassium dihydrogen phosphate: 0.1~5%, preferably 0.5-3%; magnesium sulfate: 0.05~4% , preferably 0.2-2%; corn steep liquor (on dry matter basis): 0.5-20%, preferably 1-10%.

[0196] (3) The parameters of the fermentation process are: temperature 25-45° C., preferably 30-40; pH: 3.5-5.5, air volume 0.2-0.5 vvm.

[0197] After 10-28 hours of fermentation, the removal rate of glucose is 95%-98%, the removal rate of galactose is 50%-70%, the yield of ethanol is 90-95%, and the yield of a...

example 3

[0198] Example 3, The arabinose fraction uses shikimic acid-deficient Bacillus subtilis to ferment under aerobic conditions to remove glucose and galactose to generate D-ribose. The specific process parameters are as follows: the percentages are mass percentages.

[0199] (1) Medium and culture conditions:

[0200] a. Incline medium: glucose 0.5-2%, preferably 0.8-1.6%; peptone 0.4-2%, preferably 0.8-1.5%; yeast extract 0.1-1%, preferably 0.2-0.6%; sodium chloride 0.1-1.2% , preferably 0.2-0.8%; agar 0.8-3%, preferably 1.5-2.5%; pH 6.0-8.0, preferably 6.8-7.5; culture temperature 30-40°C, preferably 32-38°C; culture time 12-36 hours, Preferably 18-24h.

[0201] B, seed culture medium: glucose 1~3%, preferably 1.5~2.2%; Corn steep liquor (in dry matter) 1~3.5%, preferably 1.5~2.5%; Yeast extract 0.1~1%, preferably 0.2~0.6%; Dipotassium hydrogen phosphate 0.1-1%, preferably 0.2-0.7%; potassium dihydrogen phosphate 0.1-0.8%, preferably 0.1-0.5%; pH 6.0-8.0, preferably 6.8-7.5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com