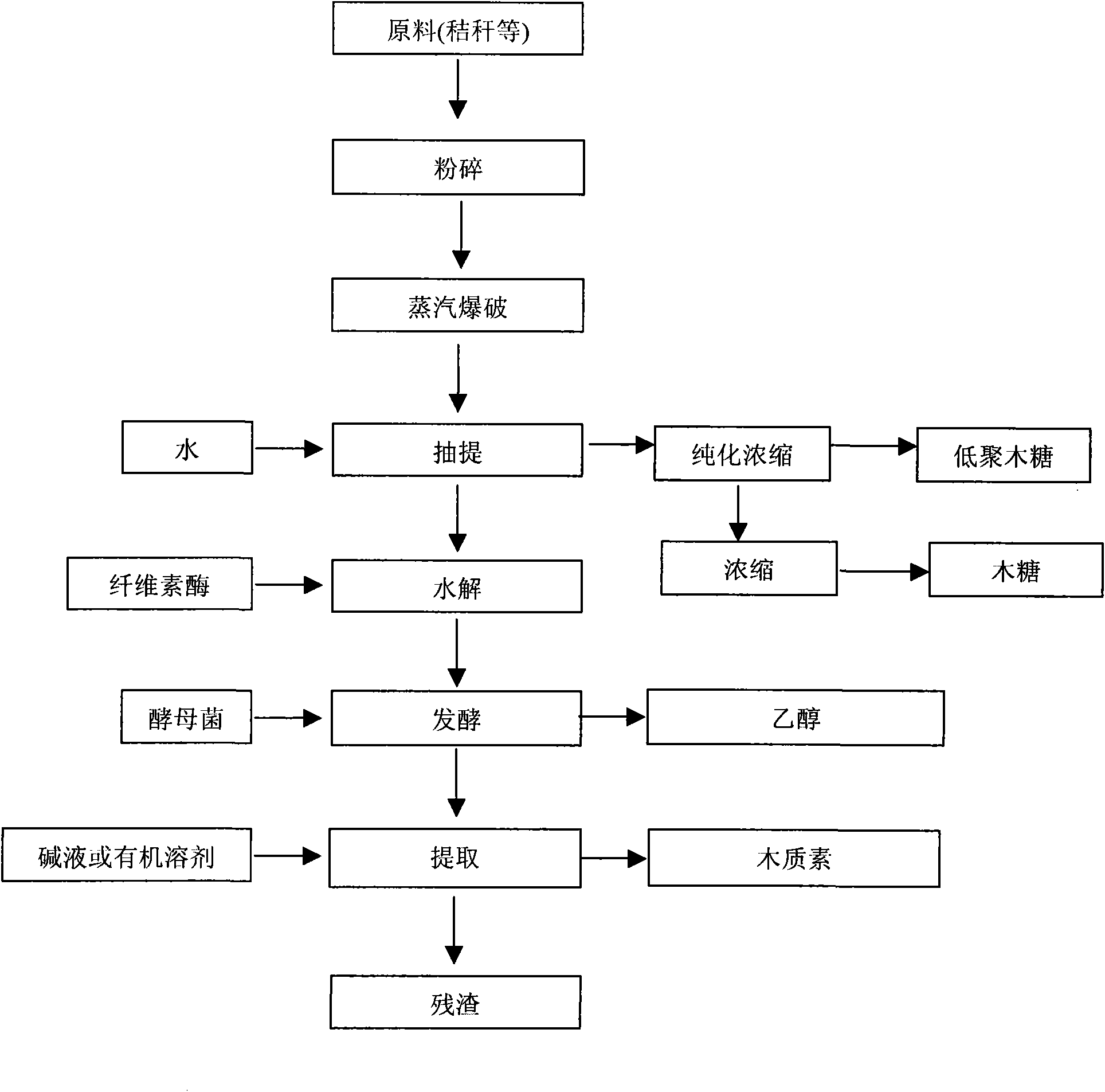

Method for utilizing straw biomass by grades

A biomass and straw technology, applied in sugar production, biofuels, lignin derivatives, etc., can solve the problems of the application effect of lignin derivatives, poor performance, and difficulty in preparing high value-added products, etc. Biomass utilization, overcoming feedback inhibition, overcoming the effect of high production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

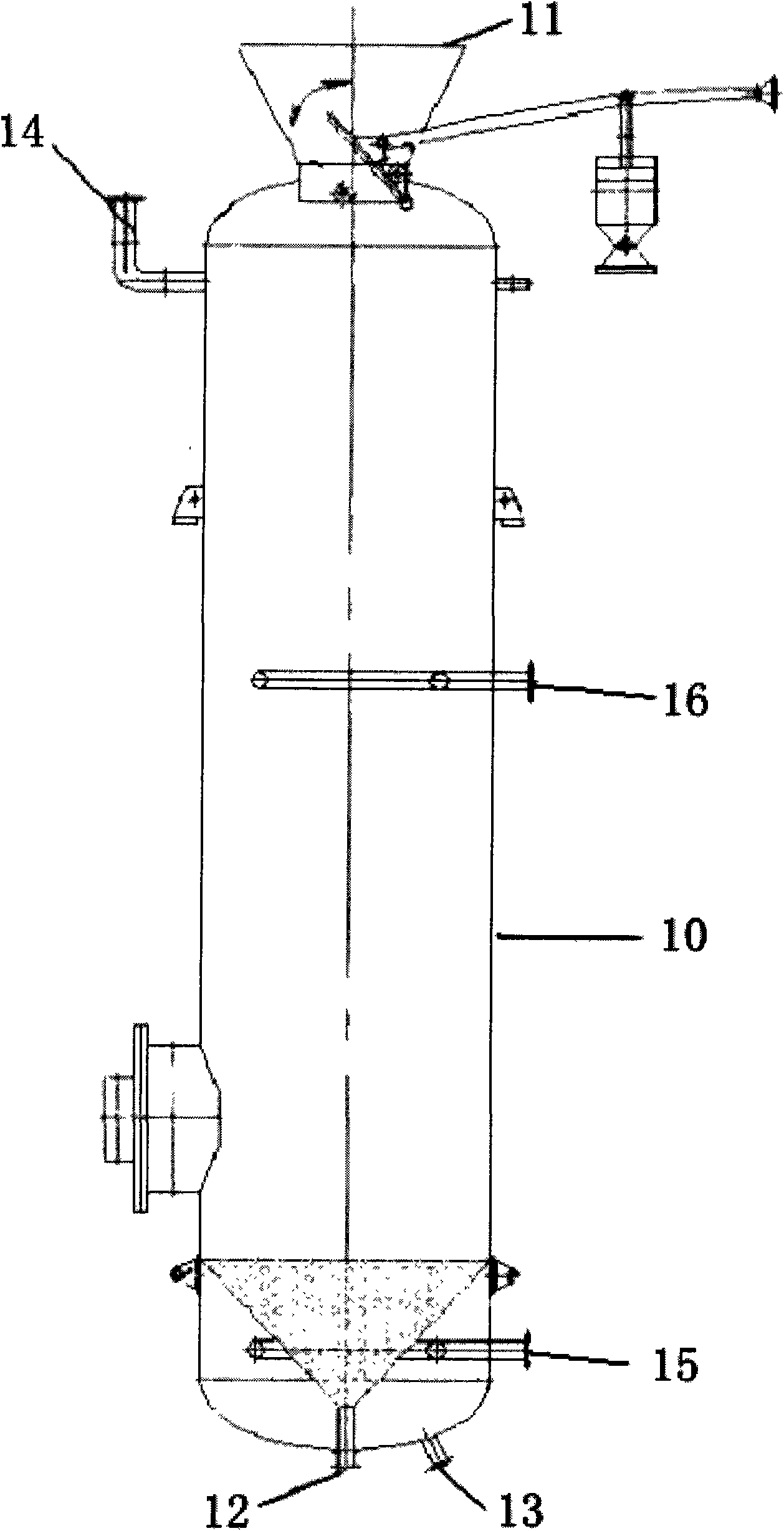

[0033] Example 1 , steam explosion (steam explosion)

[0034] In this embodiment, a steam explosion reaction tank is used to steam-explode straw materials. The steam explosion reaction tank can be, for example, the steam explosion tank disclosed in the Chinese Utility Model Patent No. 01218677.6. The specific structure is as follows figure 2 As shown, the tank body 10 is included, the top of the tank body 10 is provided with a feed port 11, and the bottom is provided with a discharge port 12 and a slag discharge port 13. In addition, the upper part of the tank body 10 is provided with a saturated steam flower tube 14, and the lower part is provided with a saturated steam flower tube 14. A saturated steam nozzle 15 is arranged, and a compressed gas mixture (air and saturated steam) nozzle 16 is provided in the middle.

[0035] As shown in Table 1, using straws such as bean stalks and corncobs as raw materials, steam explosion reaction tanks were used for steam explosion, and...

Embodiment 2

[0040] Example 2 , Separation of hemicellulose, cellulose and lignin from steam-exploded straw

[0041]The steam-exploded stalk (hemicellulose, cellulose and lignin) that embodiment 1 obtains is soaked in the hot water of 75 ℃ with the concentration of 15wt%, carries out extraction after 4 hours, to isolate water-soluble hemicellulose ( Xylose and xylooligosaccharides), water-insoluble cellulose and lignin are still retained in the straw, the specific extraction method is as follows:

[0042] a) Repeated extraction (sample 1~3)

[0043] Four times of repeated extractions were used, and the filtrate obtained from each extraction was used to extract new steam-exploded straw. The sugar concentrations of hemicellulose in the obtained extracts were 92.6g / l, 85.3g / l and 83.9g / l (corresponding to samples 1~3);

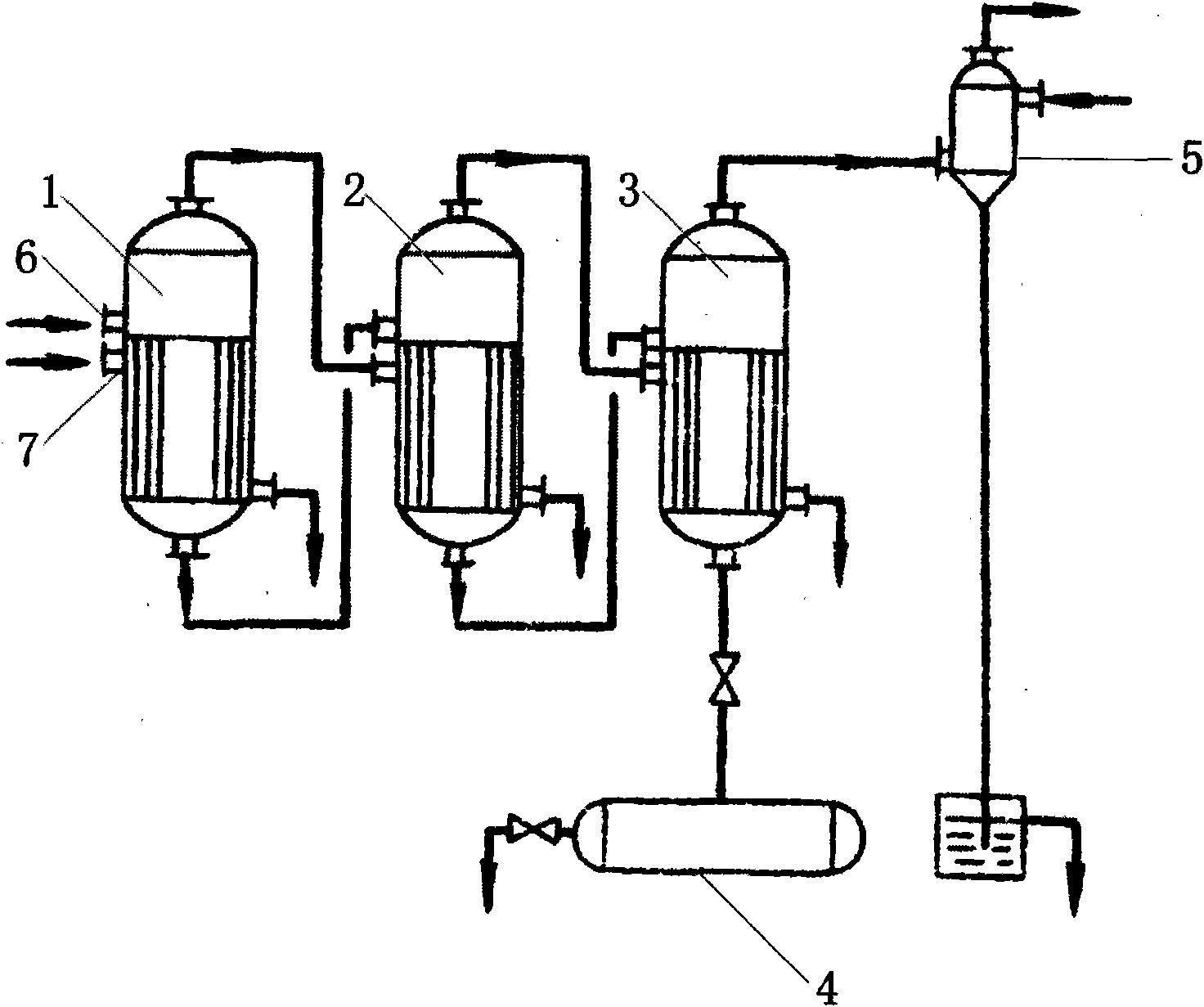

[0044] b) Continuous extraction (samples 4-6)

[0045] Adopt 4 times of continuous extraction, in the course of operation, materials and water are continuously reversely...

Embodiment 3

[0046] Example 3 , Purification and concentration of xylooligosaccharides

[0047] Get the extract obtained in Example 2, heat and concentrate to 1 / 4 of its volume, put the concentrated solution on an activated carbon chromatography column (height-to-diameter ratio is 5-10), then elute with 60% ethanol, collect the eluted Liquid was tested with 3,5-dinitrosalicylic acid method, and the collection was stopped until it no longer contained reducing sugars, and the eluents collected were combined and analyzed by HPLC. The analysis results showed that the obtained reducing sugars were active xylooligosaccharides .

[0048] Under the temperature condition of 40°C, the collected active xylooligosaccharides were evaporated under reduced pressure to remove the ethanol contained therein (which can be recycled and reused), and then the active xylooligosaccharides were obtained by nanofiltration with a content of about 50%. % syrup. The syrup is a colorless and transparent viscous slu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com