Solvent for separating biomass, and application thereof in selective separation of biomass

A biomass and solvent technology, used in applications, pulping with organic solvents, food science, etc., to achieve the effects of reducing pollution, easy modification, reducing dehydration process and energy consumption requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

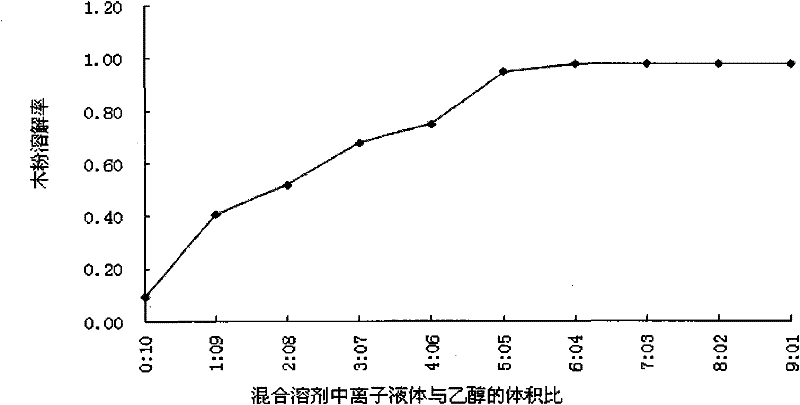

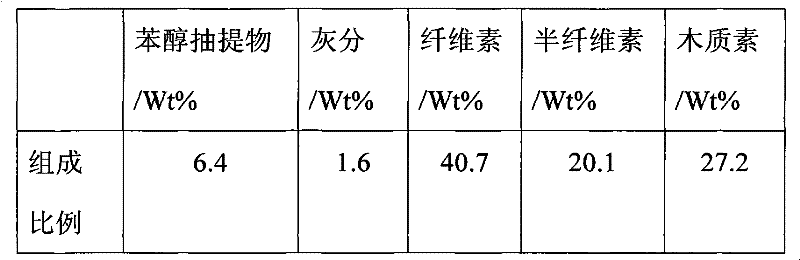

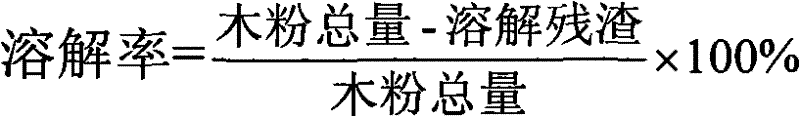

[0037] The ionic liquid used in this embodiment is [Bmin]Br (1-butyl-3-methylimidazolium bromide), the organic solvent is ethanol, and deionized water that has been distilled once. Mix the ionic liquid and ethanol according to different ratios (0:1, 1:9, 2:8, 3:7, 4:6), add water with 30% of the volume of the ionic liquid, mix it with the 40-mesh powder of masson pine and add it to the sealed In the container, the reaction container was heated, kept warm after reaching the reaction temperature of 150° C., stirred for 2 hours, taken out, and naturally cooled to room temperature. Filtration and separation, drying the filter residue at 105°C for 24 hours to obtain cellulose, adding deionized water equivalent to 10 times the volume of the filtrate to the separated filtrate, and secondary filtration and separation; the separated filter residue is lignin, collected and dried for later use; The secondary separation filtrate includes ionic liquids and hemicellulose degradation product...

Embodiment 2

[0044]The ionic liquid used in this embodiment is [Bmin]Br (1-butyl-3-methylimidazolium bromide), the organic solvent is ethanol, and deionized water that has been distilled once. Mix the ionic liquid and ethanol according to different ratios (5:5, 6:4, 7:3, 8:2, 9:1), add water with 20% of the volume of the ionic liquid, mix it with the 60-mesh powder of masson pine and add it to the sealant In the container, the reaction container was heated, kept warm after reaching the reaction temperature of 190° C., stirred for 2 hours, taken out, and naturally cooled to room temperature. Filtration and separation, when almost no filter residue is obtained, add deionized water equivalent to 10 times the volume of the filtrate to the separated filtrate, and perform secondary filtration and separation; the separated filter residue is lignin, which is collected and dried for later use; the secondary separation filtrate includes ionic liquid As well as cellulose and hemicellulose degradation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com