Lignocellulose acid/alkali coupling pretreatment method

A lignocellulose and lignin technology, applied in the field of biomass resource conversion and utilization, can solve the problems of high process energy consumption, large equipment investment, insufficient attention to the treatment of hemicellulose and lignin, etc. The effect of saving energy consumption and cheap and easy availability of solvents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

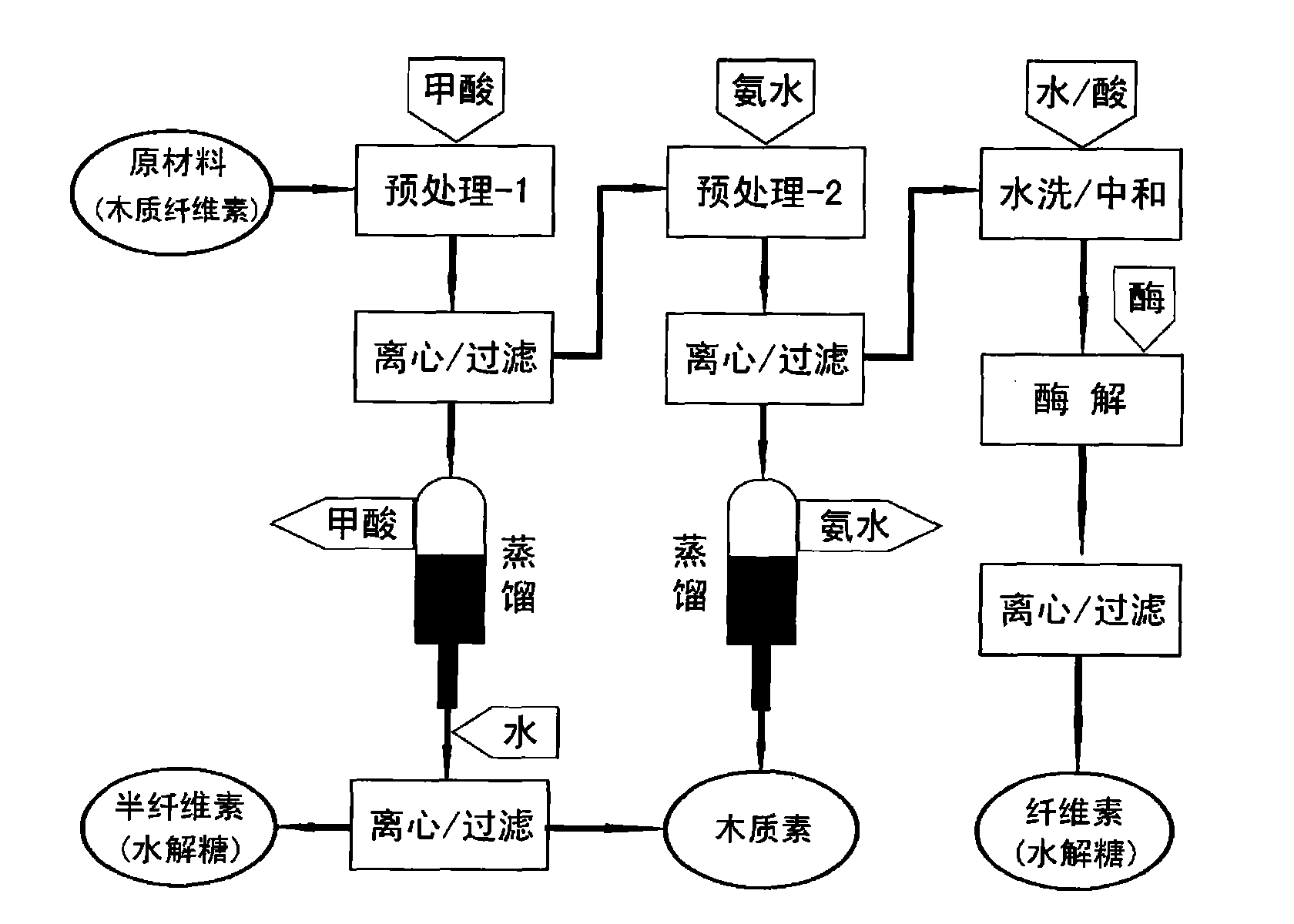

Method used

Image

Examples

Embodiment 1

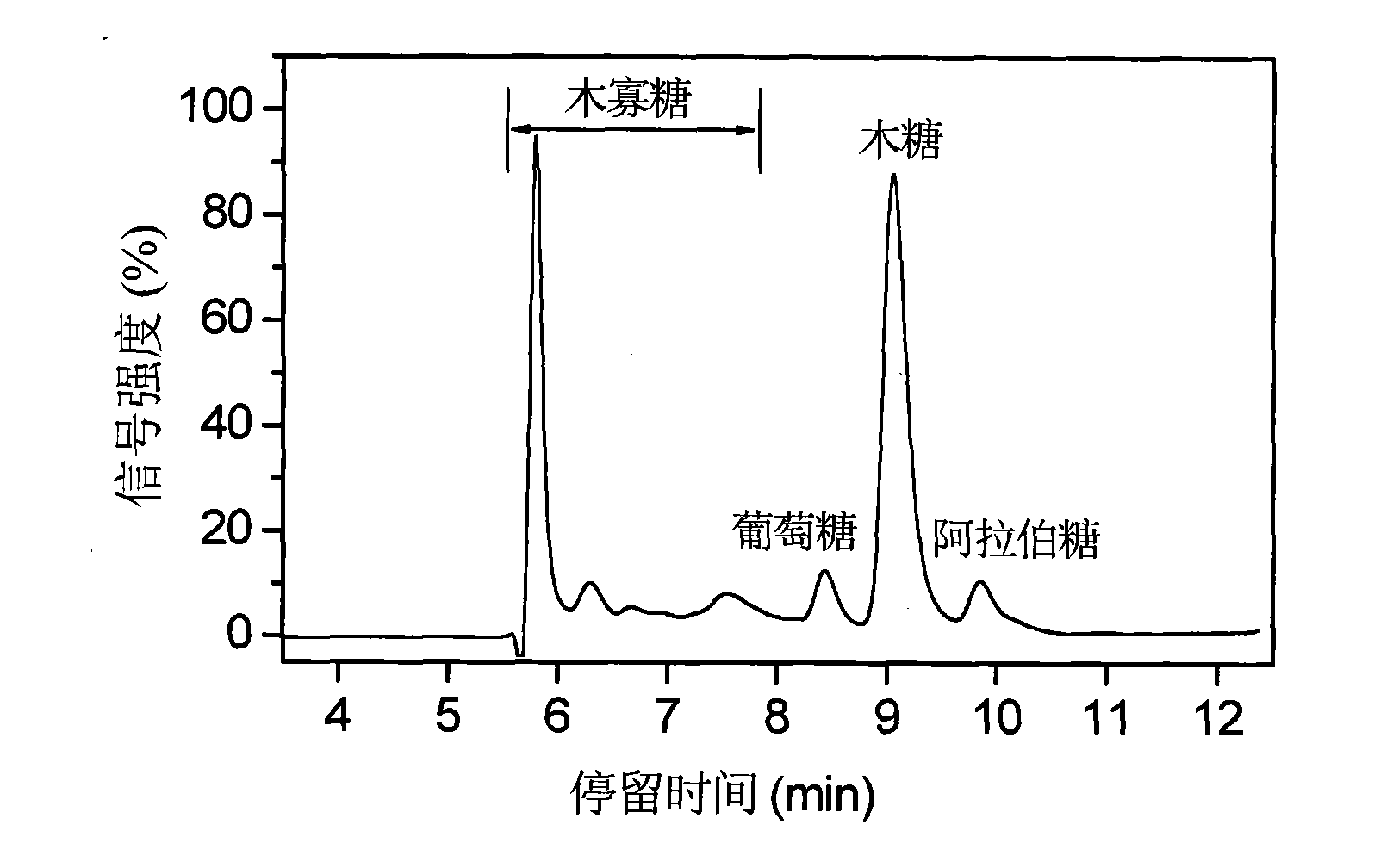

[0034] Weigh 1000 g of corn stalks with a particle size of 20-80 mm, add 15 L of formic acid (88 wt %) and 150 mL of hydrochloric acid (37 wt %), and place them in a treatment tank. After reacting in a constant temperature water bath at 65° C. and 150 rpm for 3 hours, the reaction slurry was separated from solid to liquid. (1) The liquid component reclaims formic acid and hydrochloric acid through vacuum distillation, and the formic acid recovery rate reaches 92%. Add water 500mL to dissolve hemicellulose hydrolysis sugar under normal temperature and pressure, and utilize high-performance liquid chromatography (HPLC) to analyze and detect (the results are as follows: figure 2 shown), the hemicellulose hydrolysis rate reaches 90%; the water-insoluble lignin is recovered by centrifugation or filtration. (2) The solid component is further treated with ammonia water, the treatment conditions are: concentration of ammonia water 15wt%, solid-liquid ratio 1:8, treatment temperature...

Embodiment 2

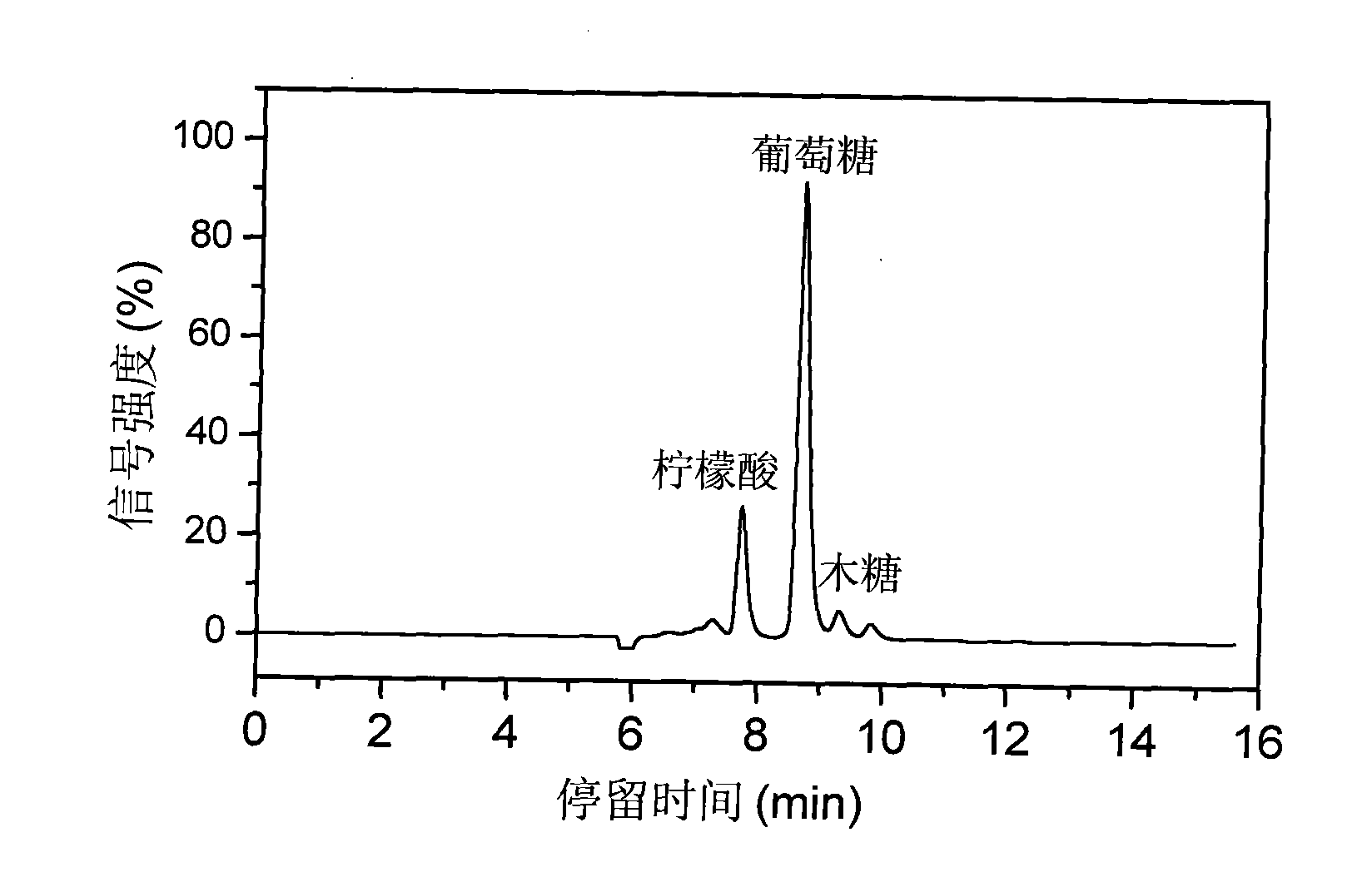

[0037] Weigh 1000g of corn stalks with a particle size of 20-80 mesh and put them into a treatment tank, and add 2wt% dilute sulfuric acid solution at a solid-to-liquid ratio of 1:15. After reacting in a pressure cooker at 120° C. for 45 minutes, the reaction slurry was separated into solid and liquid. The liquid component is used for subsequent neutralization treatment; the solid component is then treated with sodium hydroxide solution, the treatment conditions are: sodium hydroxide concentration 2wt%, solid-liquid ratio 1:10, treatment temperature 80°C and reaction time 8h. After the reaction is finished, the solid-liquid separation of the material is carried out. (1) The liquid component is neutralized with the liquid material treated with dilute sulfuric acid, and the water-insoluble lignin produced is recovered by centrifugation or filtration, and the lignin yield reaches 87%; the liquid component is analyzed and detected by HPLC, and the hemicellulose is hydrolyzed The ...

Embodiment 3

[0040] Weigh 1000 g of corn cobs with a particle size of 20 to 80 meshes, add 10 L of formic acid (88 wt%) and 100 mL of hydrochloric acid (37 wt %) and place them in a treatment tank. After reacting in a constant temperature water bath at 60° C. and 150 rpm for 3 hours, the reaction slurry was separated into solid and liquid. (1) The liquid component reclaims formic acid and hydrochloric acid through vacuum distillation, and the formic acid recovery rate reaches 92%. Water is added to dissolve the hemicellulose hydrolyzed sugar, and the hemicellulose hydrolysis rate reaches 91% through HPLC analysis and detection; the water-insoluble lignin is recovered by centrifugation or filtration. (2) The solid components are further treated with ammonia water, the treatment conditions are: ammonia water concentration 15wt%, solid-liquid ratio 1:6, treatment temperature 60°C and reaction time 12h. After the reaction, the material is separated from the solid and liquid, and the liquid co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com