A method for separating highly active lignin from agricultural and forestry biomass

A biomass and high activity technology, applied in the field of biomass refining and resource utilization, can solve the problems of less than 20% effective utilization rate and reducing the potential for high-value separation of lignin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

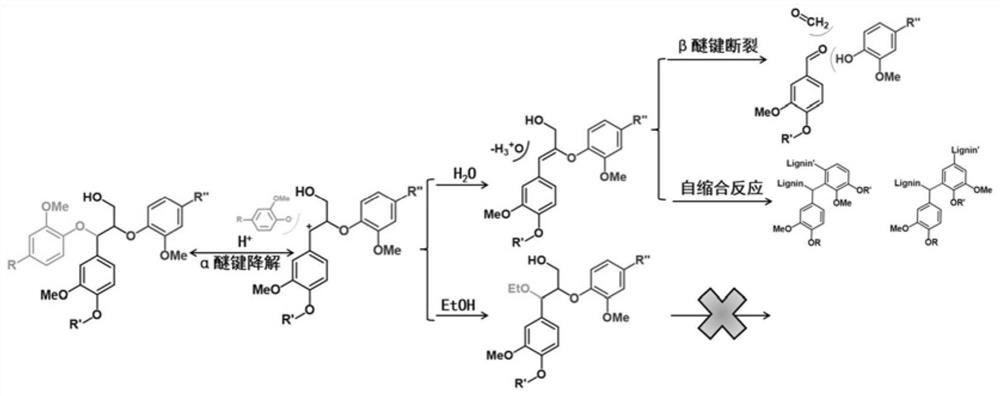

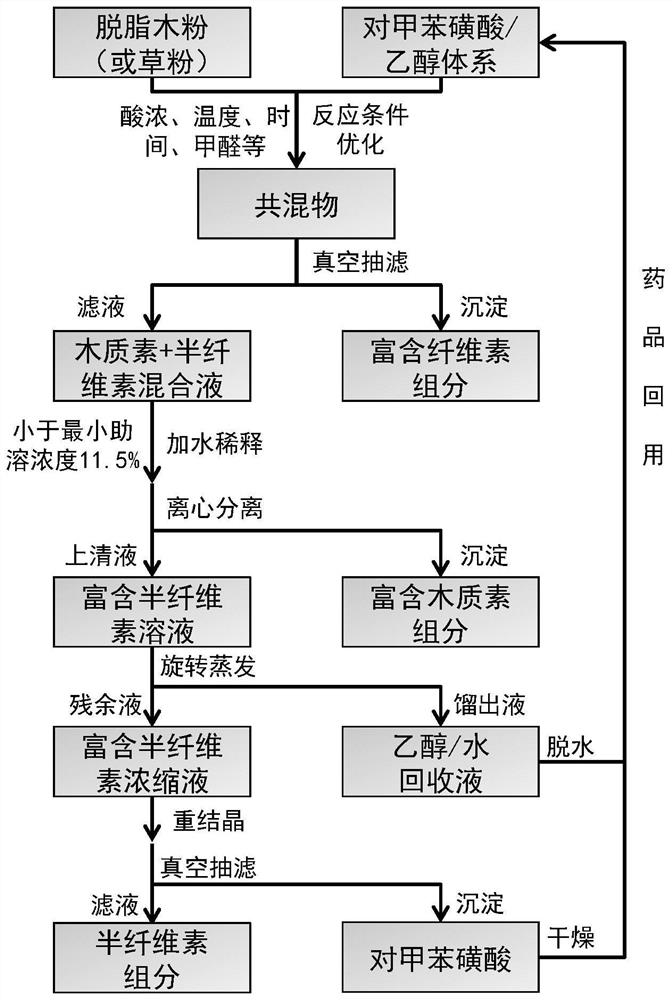

Method used

Image

Examples

Embodiment 1

[0037] The wheat straw used in the experiment was produced in Shuyang, Jiangsu. Cut the raw material to about 3 cm in length, then crush the wheat straw stalks with a plant grinder and sieve, take 20-80 mesh (accounting for 80% of the raw material) wheat straw powder, air-dry and set aside.

[0038] (1) Extract 20-80 mesh wheat grass powder with benzene alcohol (2:1, v / v) in a Soxhlet extractor at 85°C for 8 hours to remove lipids and Waxy, after extraction, the raw material is air-dried for later use.

[0039] (2) Both p-toluenesulfonic acid and ethanol are purchased from Aladdin reagents. Before preparing p-toluenesulfonic acid / ethanol solvent, p-toluenesulfonic acid must be dissolved in absolute ethanol, and the rotary evaporator should be used to remove them as much as possible. After crystallization water, compound with absolute ethanol to form the target solvent. Before and after the solution is prepared, the change of moisture is measured by a Karl Fischer moisture an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| separation | aaaaa | aaaaa |

| separation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com