Method for extracting biomass lignin by utilizing quaternary ammonium base

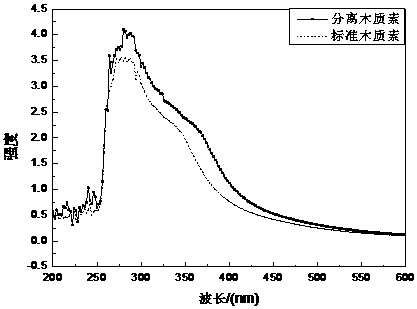

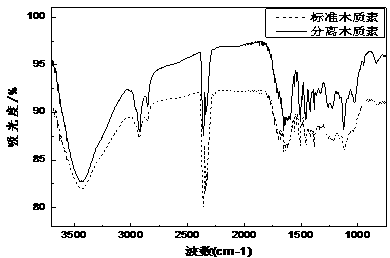

A technology of quaternary ammonium base and lignin, which is applied in the direction of lignin derivatives, chemical instruments and methods, organic chemistry, etc., can solve the problems that the extraction rate is only about 10%, the structure undergoes chemical changes, and the purity of lignin is not high. Achieve the effect of low cost, mild extraction conditions and short cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A method utilizing tetramethylammonium hydroxide to extract wheat lignin:

[0036] The dried wheat straw was extracted in a Soxhlet extractor with a benzene:ethanol solution with a volume ratio of 2:1 for 6 hours, and the residue was dried to obtain the degreased sample used in this experiment. Take 1.000g of defatted and dewaxed straw, use the Klason method to measure the lignin content in wheat straw, measure three times in parallel, and take the average value.

[0037] Accurately weigh 10g of dried wheat straw, add 200ml of tetramethylammonium hydroxide with a mass concentration of 24%, treat it in a constant temperature water bath at a temperature of 50°C for 14h, filter it with gauze while it is hot, adjust the pH of the filtrate to 5.5 with acetic acid, and depressurize Concentrate, treat with three volumes of 95% ethanol and vacuum filter. The filtrate was distilled off under reduced pressure to remove ethanol, then the pH was adjusted to 2.0 with 6 mol / L HC...

Embodiment 2

[0040] A method utilizing tetraethylammonium hydroxide to extract corn stalk lignin:

[0041] Wash and dry the corn stalks, and pulverize them with a pulverizer for later use. Take 1.000g of defatted and dewaxed straw, and use the Klason method to determine the lignin content in wheat straw. The content of lignin in wheat straw was measured three times in parallel, and the average value was 12.78%.

[0042]Accurately weigh 10g of dried corn stalks, add 200ml of 20% tetraethylammonium hydroxide, treat in a constant temperature water bath at a temperature of 50°C for 10h, filter with gauze while it is hot, adjust the pH of the filtrate to 5.5 with acetic acid, and concentrate under reduced pressure , treated with three volumes of 95% ethanol and vacuum filtered. The filtrate was distilled under reduced pressure to remove ethanol, and then adjusted to pH 2.0 with 6 mol / L HCl solution, centrifuged, and freeze-dried. The obtained product was corn straw lignin, and the calculated l...

Embodiment 3

[0045] A method of extracting wheat lignin with tetrabutyl ammonium hydroxide:

[0046] Wash and dry the wheat stalks, and pulverize them with a pulverizer for later use. Take 1.000g of defatted and dewaxed straw, and use the Klason method to determine the lignin content in wheat straw. The content of lignin in wheat straw is measured three times in parallel, and the average value is 18.75%.

[0047] Accurately weigh 10g of dried wheat straw, add an appropriate amount of tetraethylammonium hydroxide with a concentration of 20%, treat it in a constant temperature water bath at a temperature of 50°C for 15 hours, filter it with gauze while it is hot, adjust the pH of the filtrate to 5.5 with acetic acid, and reduce pressure Concentrate, treat with three volumes of 95% ethanol and vacuum filter. The filtrate was distilled under reduced pressure to remove ethanol, then adjusted to pH 2.0 with 6 mol / L HCl solution, centrifuged, and freeze-dried. The product obtained was wheat lign...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com