Method for producing L-arabinose and D-xylose

A technology of arabinose and production method, applied in the field of fermentation products, can solve the problems of arabinose fermentation loss, fermentation, consumption of arabinose, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

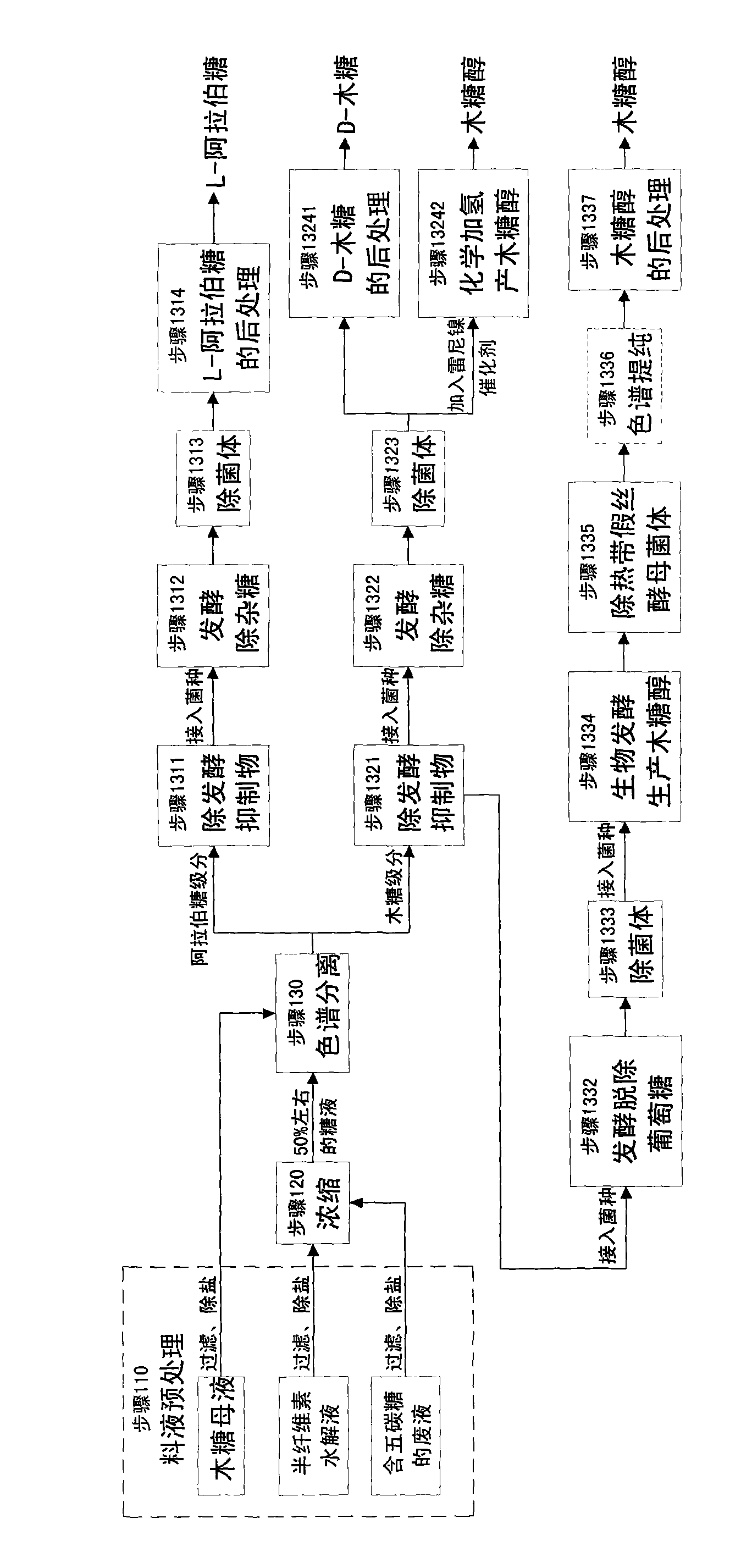

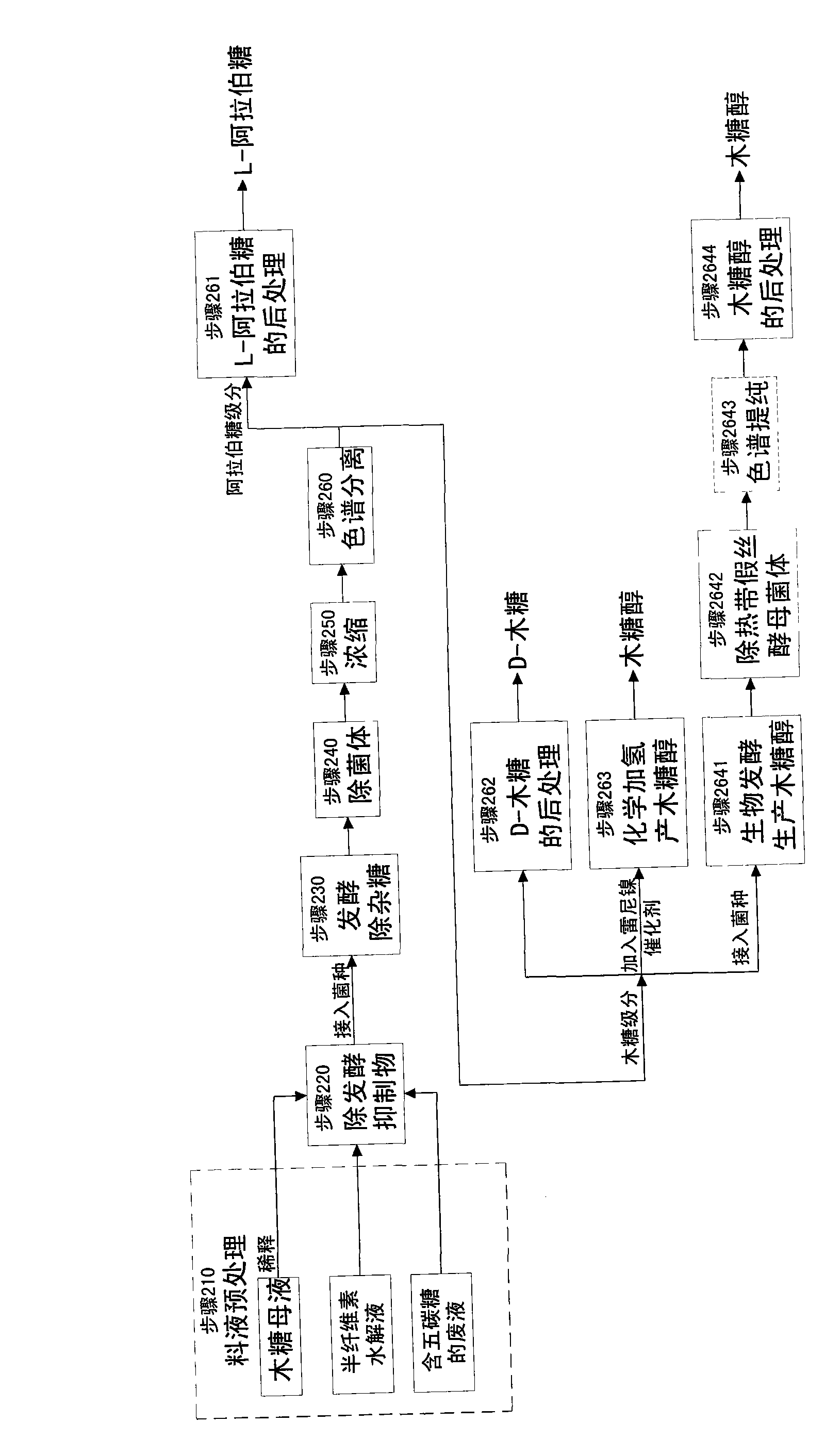

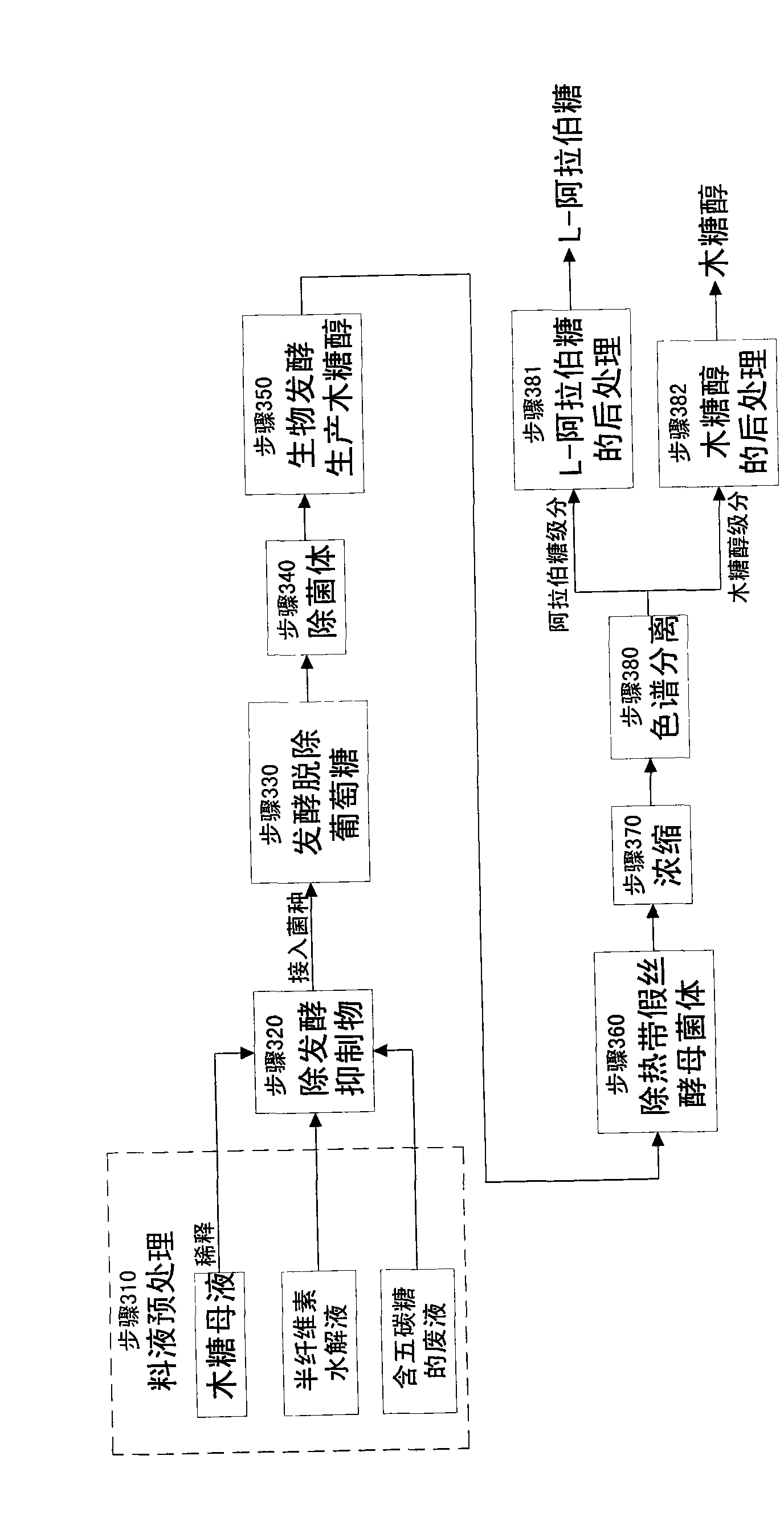

Method used

Image

Examples

example 1

[0226] Example 1 The specific process parameters for the arabinose fraction to use Saccharomyces cerevisiae to ferment glucose and galactose to produce ethanol under anaerobic conditions are as follows: the percentages are mass percentages.

[0227] (1) first adjust the sugar concentration of the arabinose solution to 10-40%, preferably 20-35%;

[0228] (2) The composition of the culture medium nutrient salt is: urea or ammonium sulfate: 0.01~0.5%, preferably 0.05~0.2%; Potassium dihydrogen phosphate: 0.01~0.5%, preferably 0.01~0.2%; Magnesium sulfate: 0.01~0.2% 0.4%, preferably 0.01-0.2%;

[0229] (3) Process parameters: pH: 2.5~5, temperature 33~45°C, no air or a small amount of air (0.1~0.3vvm) at the beginning of fermentation, when the cell concentration reaches 10 8 per ml, stop the ventilation and carry out anaerobic fermentation, and the fermentation time is 8-22 hours;

[0230] (4) Conversion results: the removal rate of glucose is 97.15-98.5%, the removal rate of ...

example 2

[0231] Example 2 The arabinose fraction uses Saccharomyces cerevisiae to ferment under aerobic conditions to remove glucose and galactose to generate ethanol, carbon dioxide and water. The specific process parameters are as follows: the percentages are mass percentages.

[0232] (1) first adjust the sugar concentration of the arabinose solution to 8-30%, preferably 10-25%;

[0233] (2) The composition of the culture medium nutrient salt is: ammonium sulfate: 0.1~3.5%, preferably 0.5~2.5%; potassium dihydrogen phosphate: 0.1~5%, preferably 0.5~3%; magnesium sulfate: 0.05~4% , preferably 0.2 to 2%; corn steep liquor (on a dry basis): 0.5 to 20%, preferably 1 to 10%;

[0234] (3) Process parameters: pH: 3.5-5.5, temperature 25-45°C, preferably 30-40°C; air volume 0.2-0.5vvm, fermentation time 8-22h;

[0235] (4) Transformation results: the removal rate of glucose is 95%-98%, the removal rate of galactose is 50%-70%, the yield of ethanol is 90-95%, and the yield of arabinose is...

example 3

[0236] Example 3 The arabinose fraction uses shikimic acid-deficient Bacillus subtilis to ferment under aerobic conditions to remove glucose and galactose to generate D-ribose. The specific process parameters are as follows: the percentages are mass percentages.

[0237] (1) Medium and culture conditions:

[0238] a. Incline medium: glucose 0.5-2%, preferably 0.8-1.6%; peptone 0.4-2%, preferably 0.8-1.5%; yeast extract 0.1-1%, preferably 0.2-0.6%; sodium chloride 0.1-1.2% , preferably 0.2-0.8%; agar 0.8-3%, preferably 1.5-2.5%; pH 6.0-8.0, preferably 6.8-7.5; culture temperature 30-40°C, preferably 32-38°C; culture time 12-36h, preferably 18~24h.

[0239] B, seed culture medium: glucose 1~3%, preferably 1.5~2.2%; Corn steep liquor (in dry matter) 1~3.5%, preferably 1.5~2.5%; Yeast extract 0.1~1%, preferably 0.2~0.6%; Dipotassium hydrogen phosphate 0.1-1%, preferably 0.2-0.7%; potassium dihydrogen phosphate 0.1-0.8%, preferably 0.1-0.5%; pH 6.0-8.0, preferably 6.8-7.5; cult...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com