Patents

Literature

42results about How to "Reduce complicated steps" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method of preparing modified imvite for polymer/inorganic nano composite material

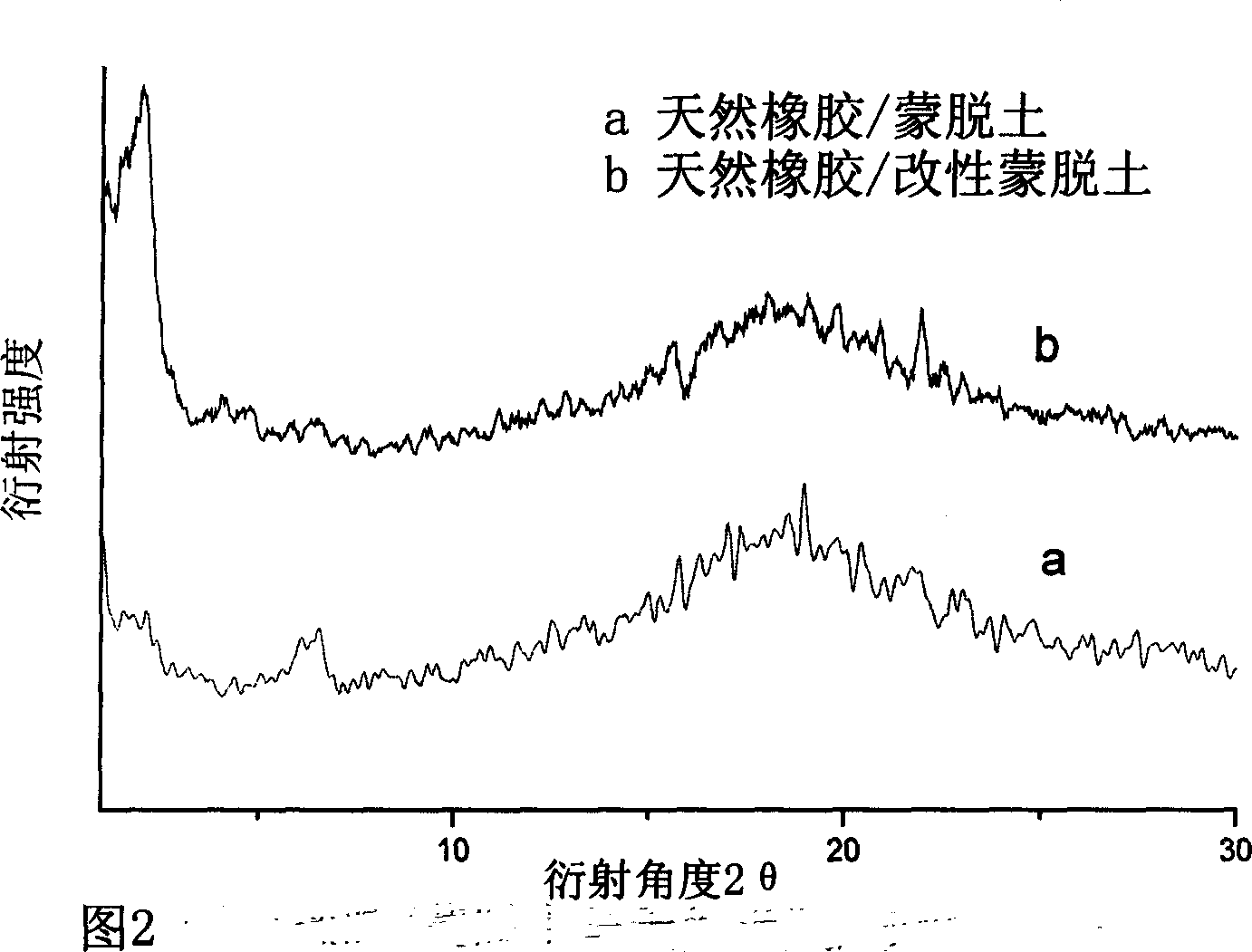

A process for preparing the modified montmorillonite used to prepare composite polymer / montmorillonite nano-material with excellent properties features the direct reaction between powdered montmorillonite and organic modifier. Its advantages are no need of water and solvent, and no environmental pollution.

Owner:SOUTH CHINA UNIV OF TECH

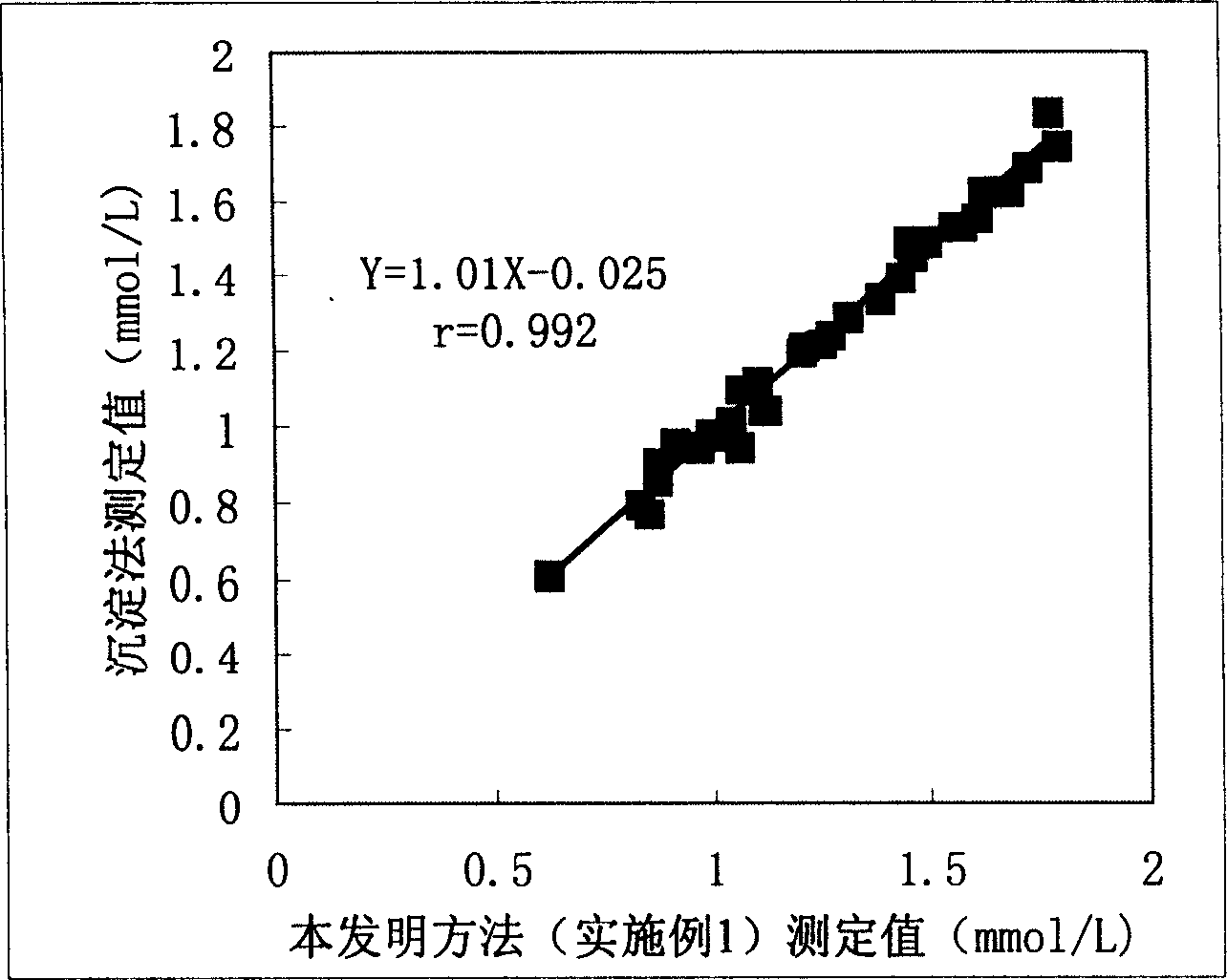

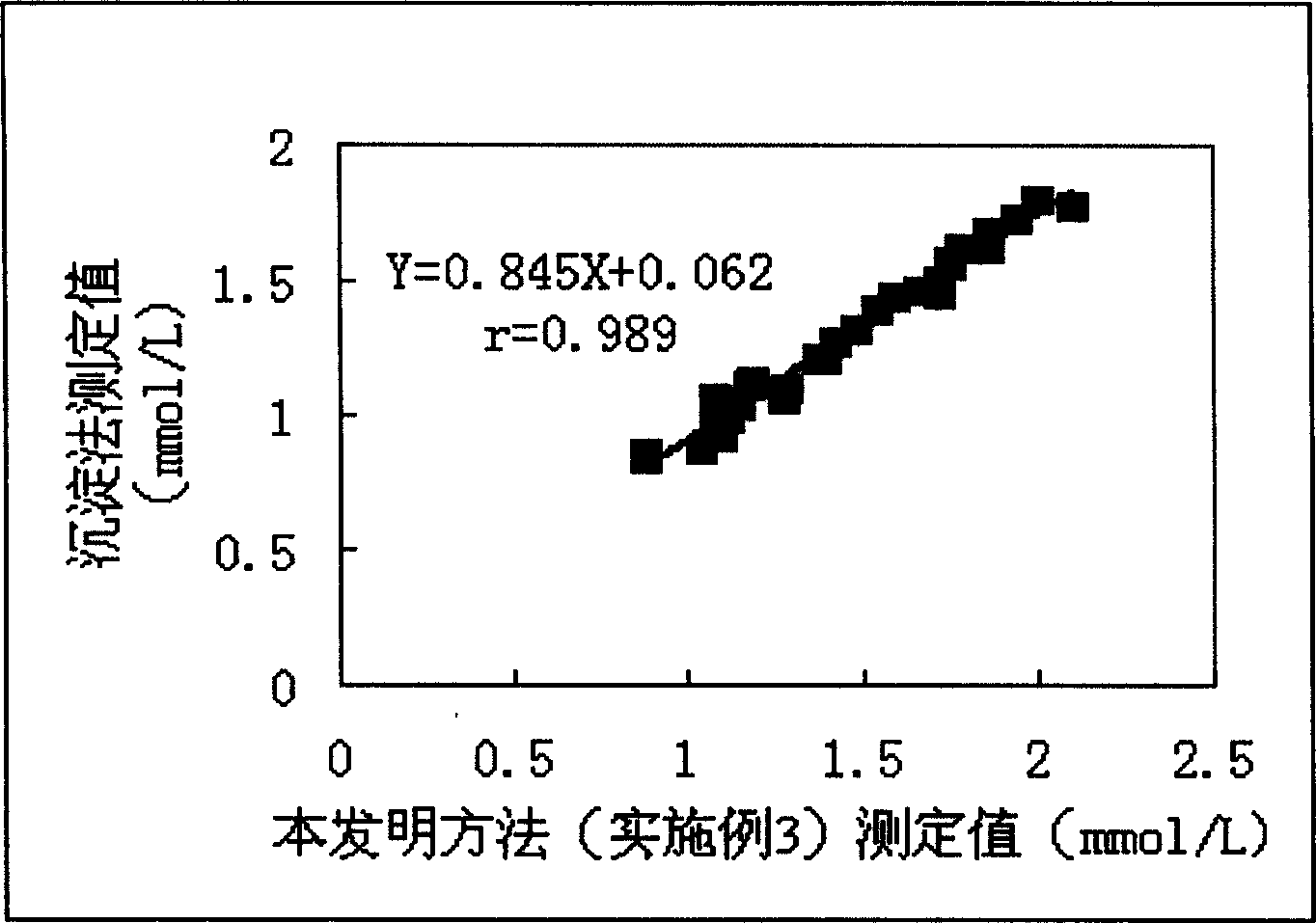

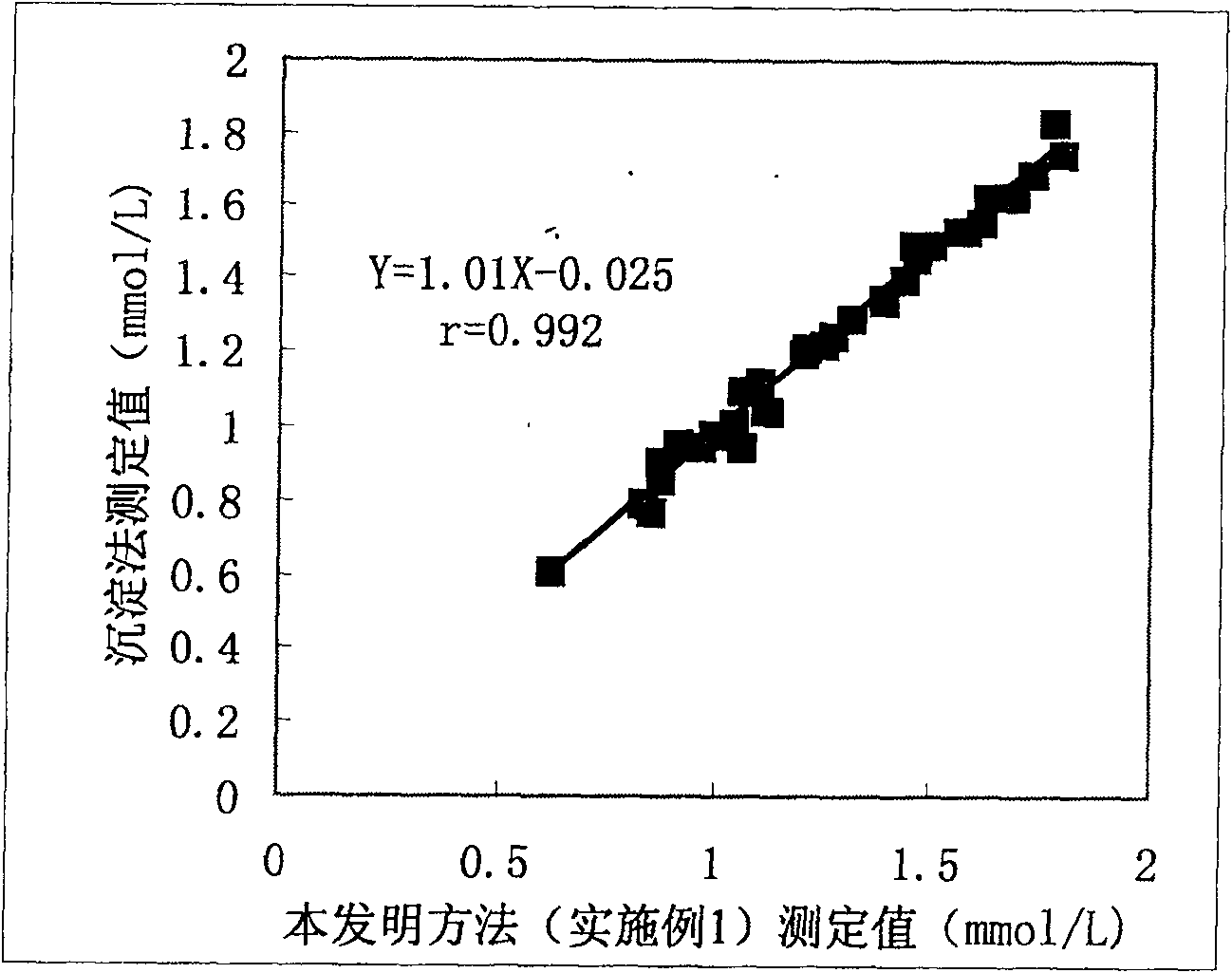

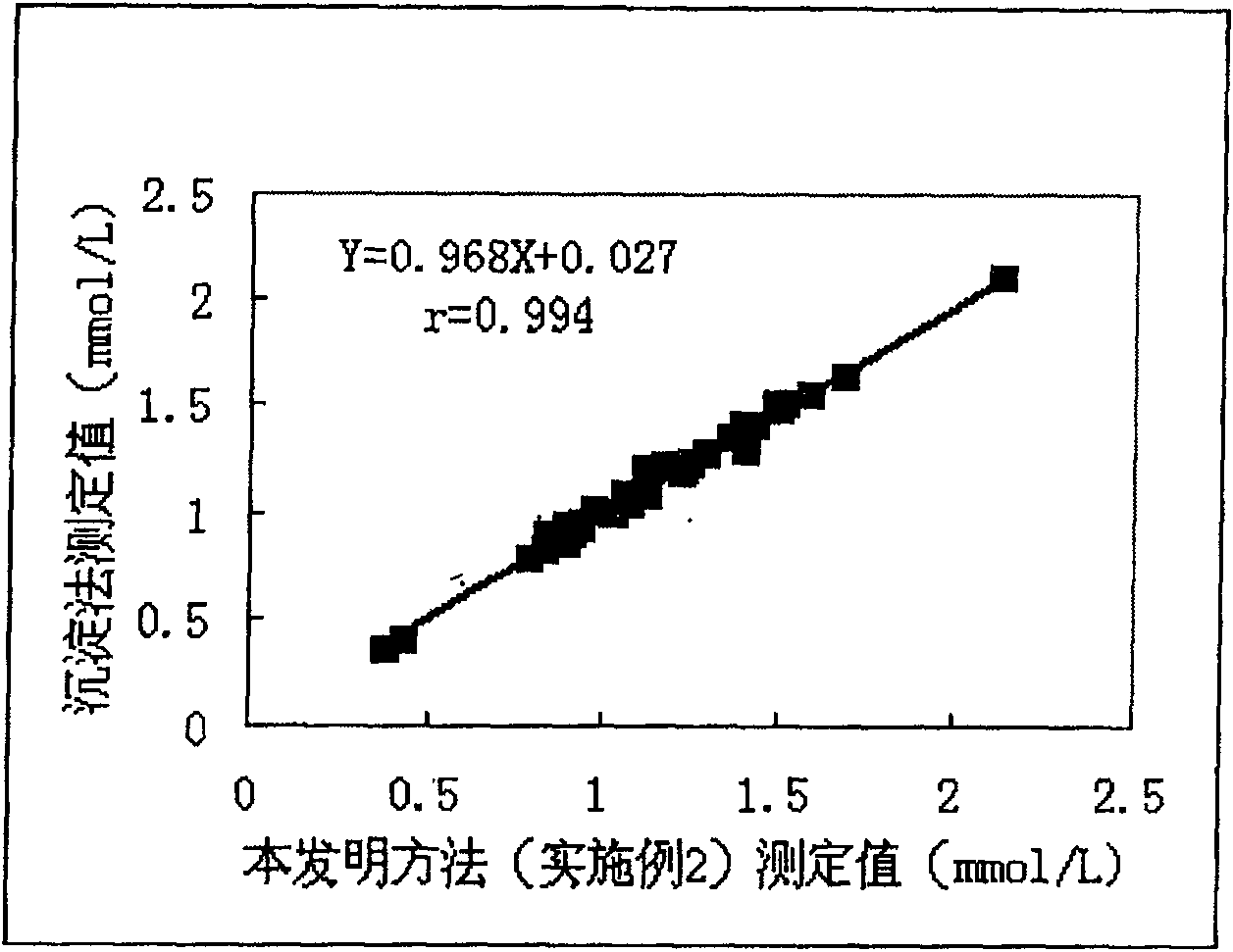

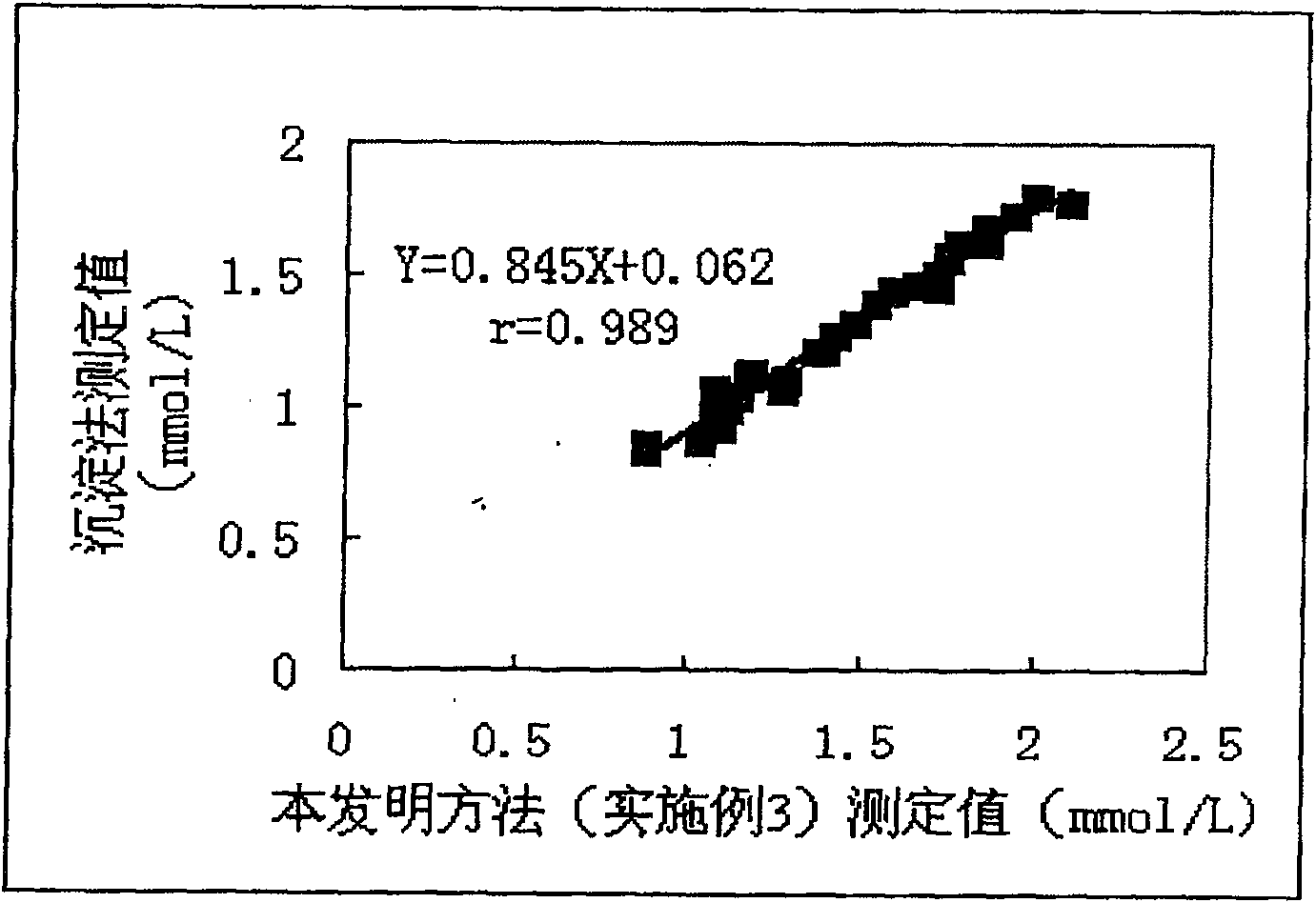

Determination reagent for cholesterol in high density lipoprotein and preparing method thereof

ActiveCN1632541AImprove accuracyStrong specificityMaterial analysis by observing effect on chemical indicatorMicrobiological testing/measurementTest agentHigh intensity

This invention relates to a test agent and its process method to test the cholesterin in the lipoprotein with high intensity in blood serum. This invention aims to provide an improvement of the agent and its process method by which we can get the agent able to automatic biochemical analysis device in each type. The technique project and the contents are the flowing: a, high combining enzyme compound; b, surface activity agent; c, some antiseptic agent, stabilization agent and color source.

Owner:浙江伊利康生物技术有限公司

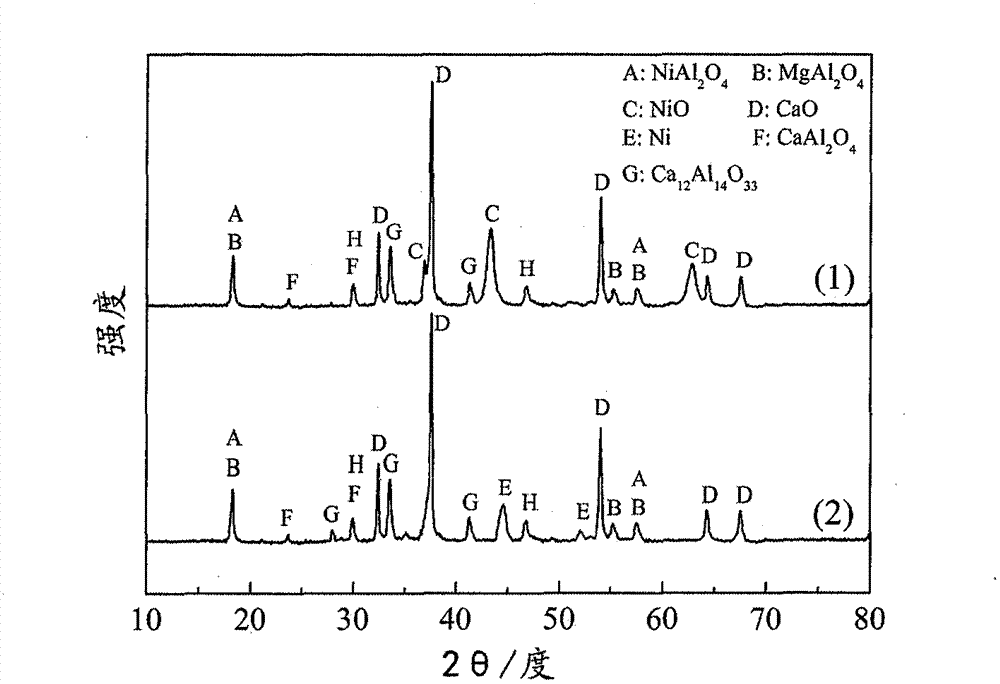

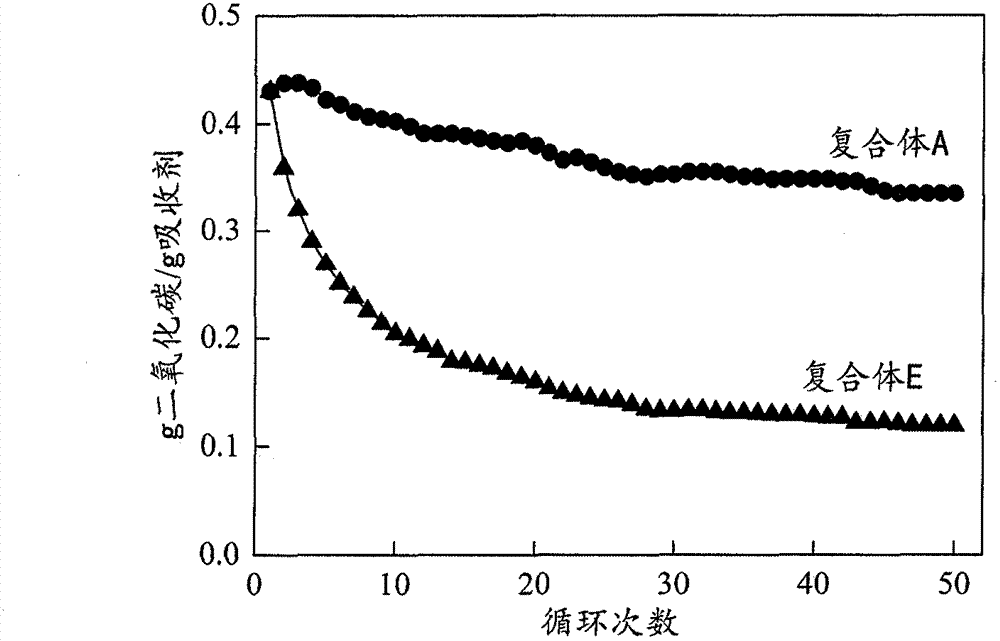

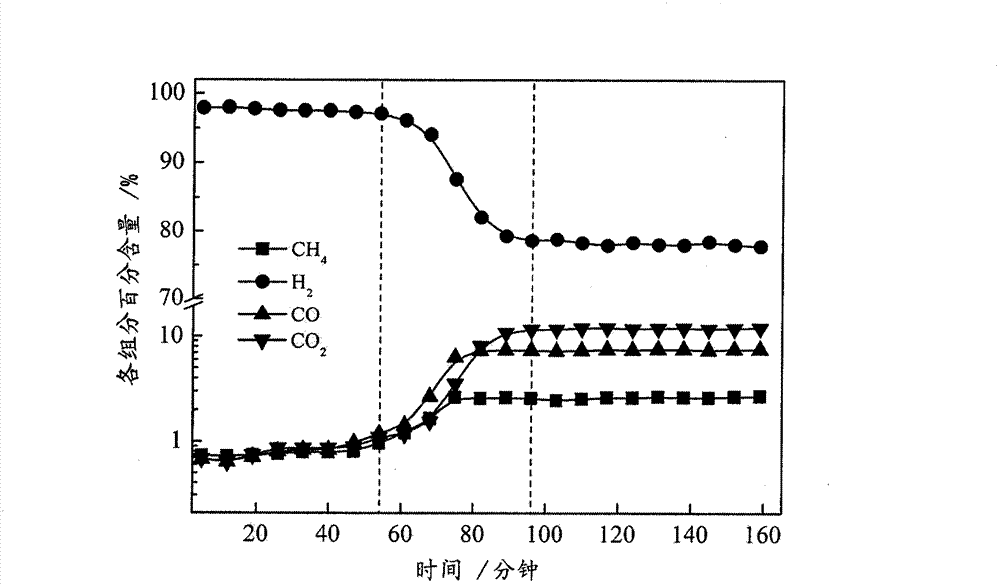

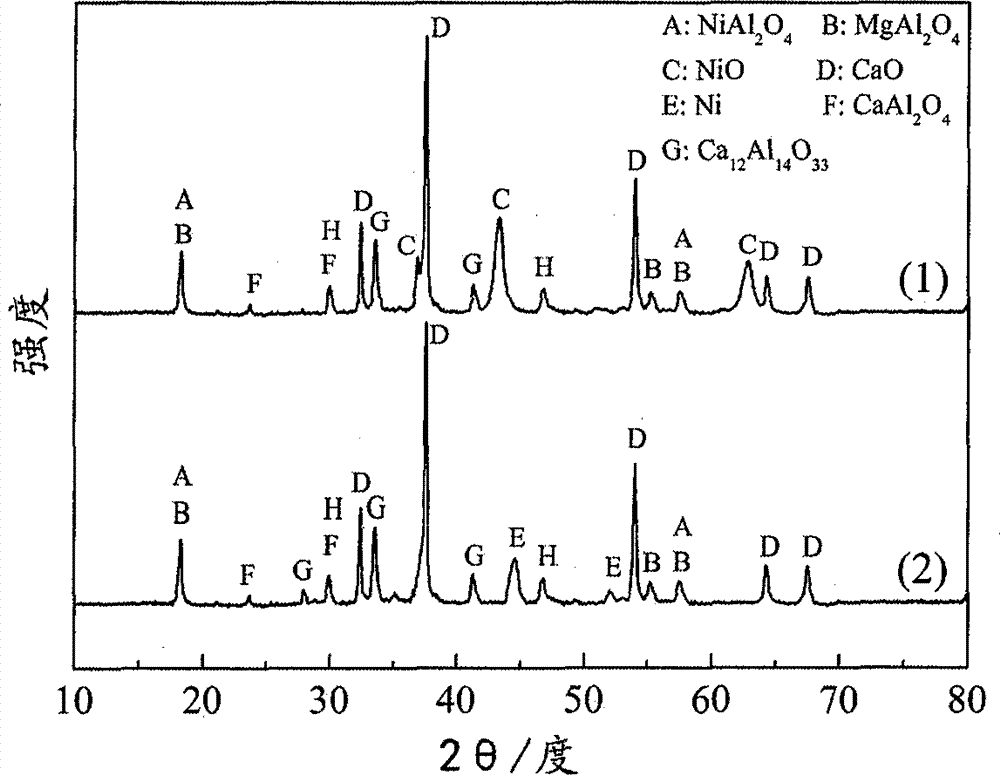

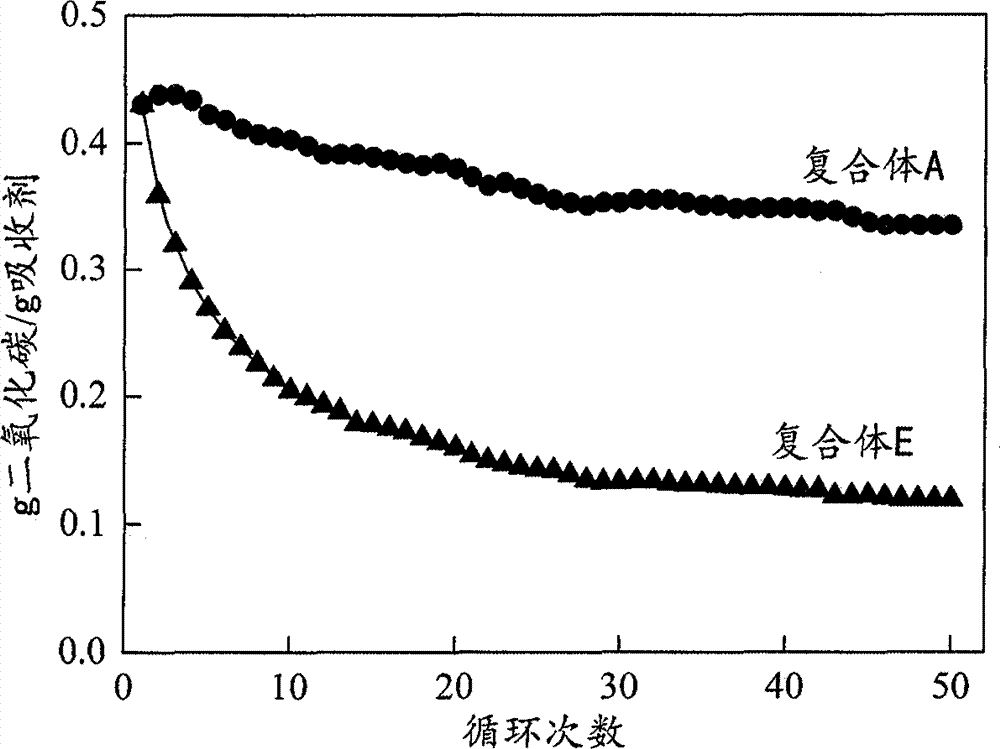

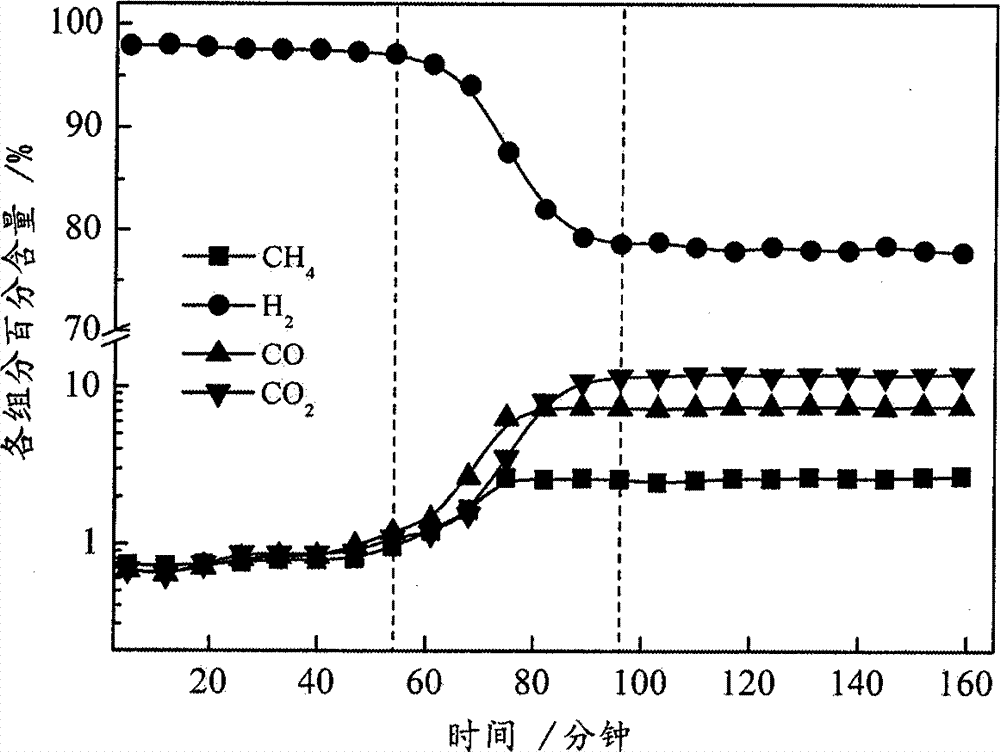

Catalyst-absorbent complex for absorbing and strengthening low-carbon hydrocarbon steam reforming hydrogen and preparing method of complex

InactiveCN102949997AImprove catalytic performancePromote absorptionProductsHydrogenSteam reformingPtru catalyst

The invention discloses a catalyst-absorbent complex for absorbing and strengthening low-carbon hydrocarbon steam reforming hydrogen and a preparing method of the complex, which are mainly used for the steam reforming hydrogen production through low-carbon hydrocarbons of C1-C4 and the like. The method is characterized in that a coprecipitation method is adopted to organically combine a catalyst for hydrocarbon steam reforming reaction and an absorbent for CO2 carboxylation reaction to form a whole body, so that micro-scale uniform distribution is realized, thus a precursor with a hydrotalcite structure is formed, and the catalyst-absorbent complex is prepared through high temperature sintering. The complex can effectively stimulate CO2 situ absorption, and excellent catalyzing and absorbing activities and stability of the complex are maintained through the hydrotalcite structure of the precursor. The chemical formula of the complex is Nix-Mgy-Caz-Al-O.

Owner:EAST CHINA UNIV OF SCI & TECH

Method for simultaneously measuring Cr, Ni and Ti in stainless steel 1Cr18Ni9Ti

InactiveCN103645189AFew stepsSave time and costMaterial analysis by observing effect on chemical indicatorColor/spectral properties measurementsChromiumTitanium

The invention belongs to the technical field of aeronautical materials, and particularly relates to a method for simultaneously measuring Cr, Ni and Ti in stainless steel 1Cr18Ni9Ti. The method comprises the steps of measuring the Cr by a hydrochloric acid method, measuring Ni by a high-Cr steel Ni reagent colorimetric method, and measuring Ti by an antipyrine methane colorimetric method. According to the method, the measurement of the Cr, the Ni and the Ti in the stainless steel can be integrated, the samples are weighed and dissolved in a unified way, and then the samples are respectively tested after being separated, so that the original complicated steps are reduced, the time and the cost are saved, and the testing efficiency is greatly increased.

Owner:SHAANXI AIRCRAFT CORPORATION

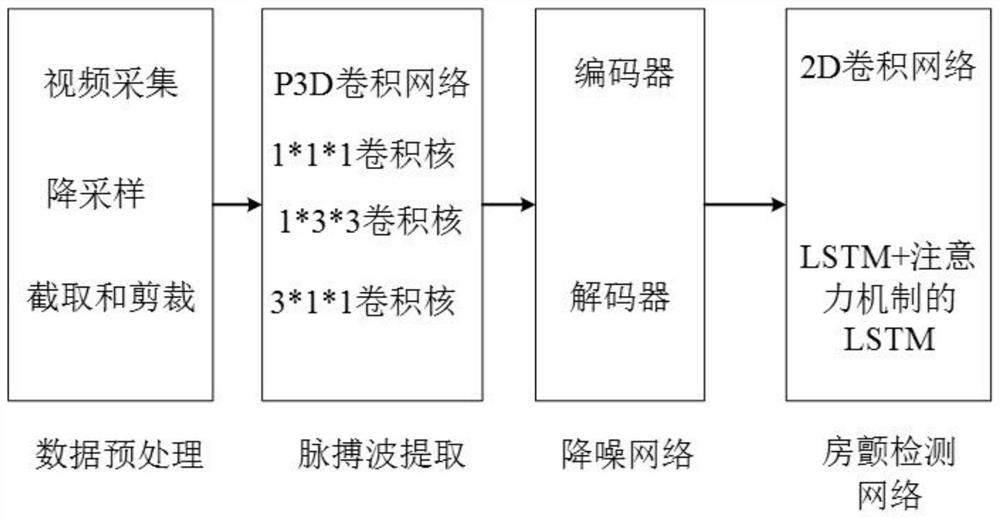

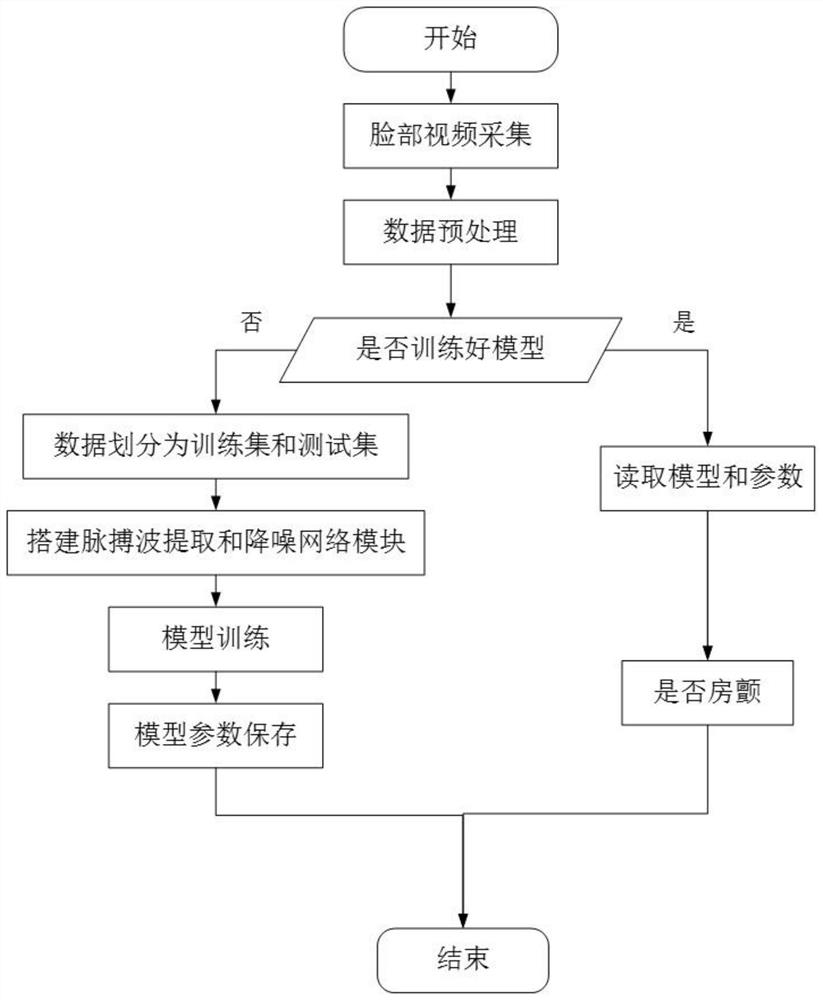

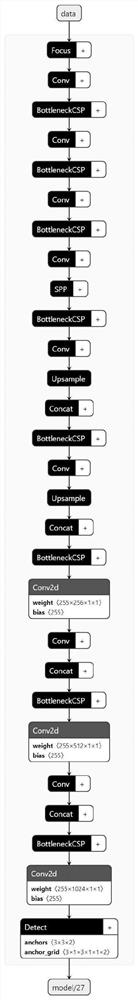

End-to-end non-contact atrial fibrillation automatic detection system and method based on vPPG signal

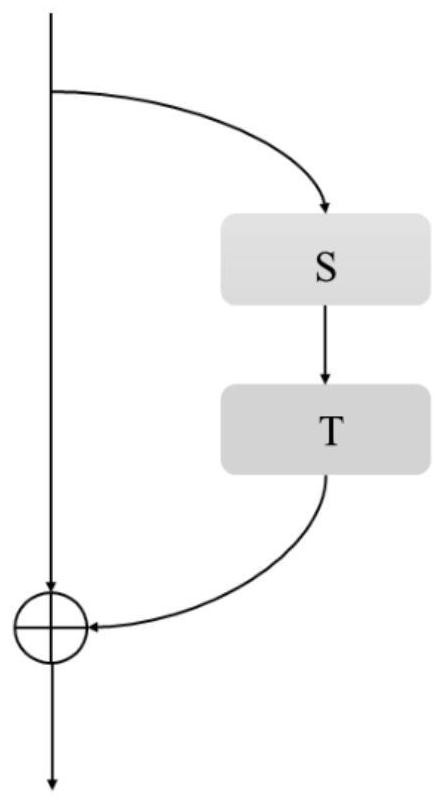

ActiveCN112587153AAccurate identificationReduce complicated stepsCatheterSensorsTerm memoryComputer science

The invention discloses an end-to-end non-contact atrial fibrillation automatic detection system based on a vPPG signal. The system comprises a data preprocessing module which is used for recording aface video of a to-be-detected user, removing the positions, with large beginning and ending noise interference, of the recorded video, carrying out downsampling, and cutting the video to be with theunified length and size; a pulse wave extraction module which is used for extracting the vPPG signal of the face video through a P3D convolutional neural network; a data denoising module which is usedfor denoising vPPG data based on a neural network of FCN-DN; and an atrial fibrillation detection module which is firstly used for training a model to enable the model to learn to divide an atrial fibrillation segment and a non-atrial fibrillation segment, and then inputting a vPPG signal segment to be detected into the trained atrial fibrillation detection model so as to judge whether the vPPG signal to be detected contains the atrial fibrillation segment or not. A parallel network combining a long-term and short-term memory network containing an attention mechanism and a convolutional network provided by the invention enables the detection of the model to be comprehensive, high in precision and good in effect.

Owner:HEFEI UNIV OF TECH

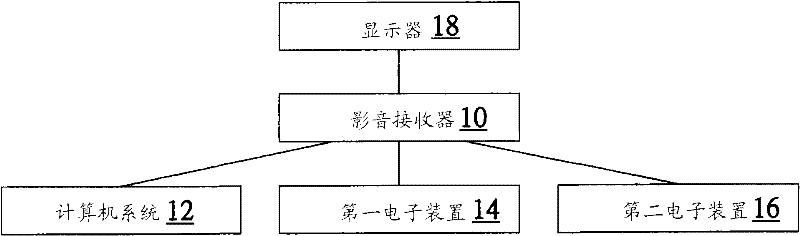

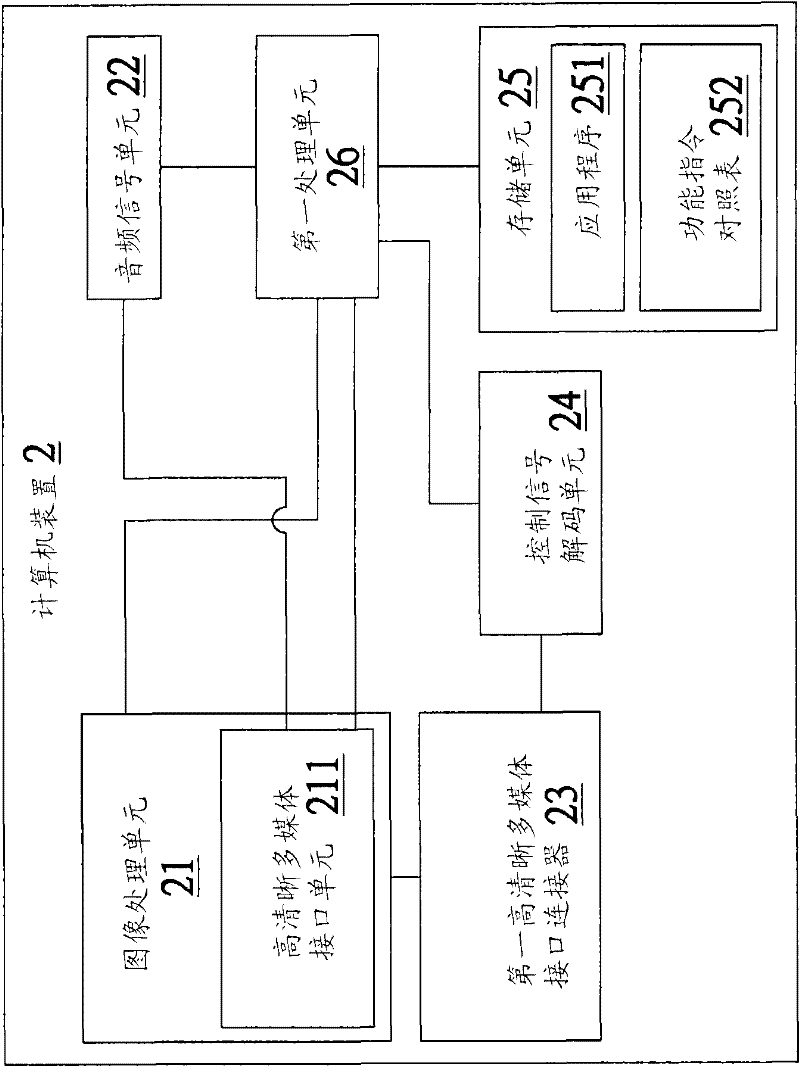

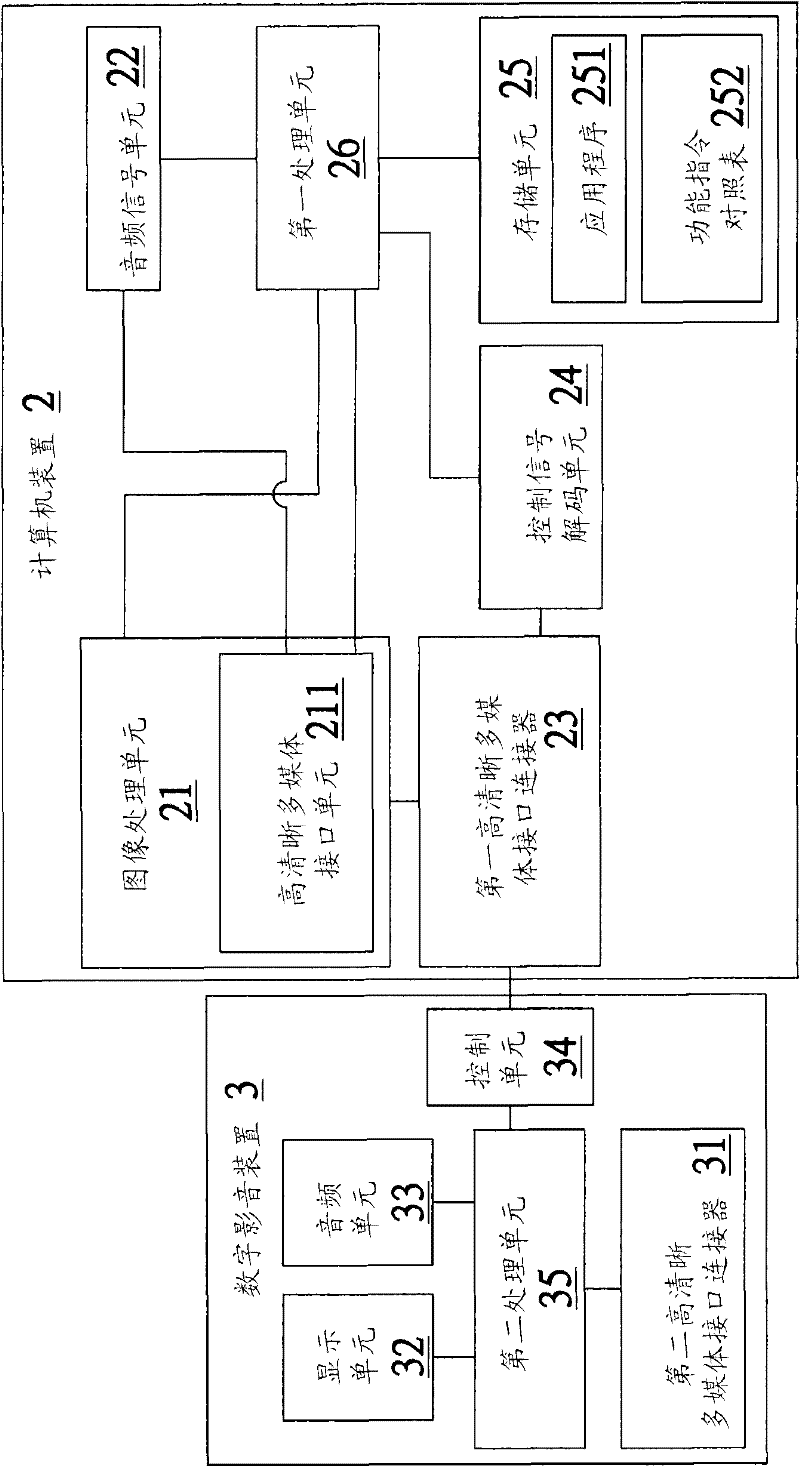

Computer device, digital electronic system and control method thereof

InactiveCN102238359AReduce complicated stepsTelevision system detailsVolume/mass flow measurementElectronic systemsControl signal

The invention discloses a computer device, a digital electronic system and a control method thereof. The control method for the digital electronic system comprises the following steps of: connecting the computer device to a digital audio and video device; executing an application program of the computer device, and transmitting a control signal to the digital audio and video device after audio and video contents are selected; when the digital audio and video device is in a standby state, starting the digital audio and video device, and performing switching to a computer device channel; and playing the audio and video contents of the computer device in the digital audio and video device. Therefore, the inconvenience of film watching realized by utilizing a high-definition multimedia interface is reduced.

Owner:ACER INC

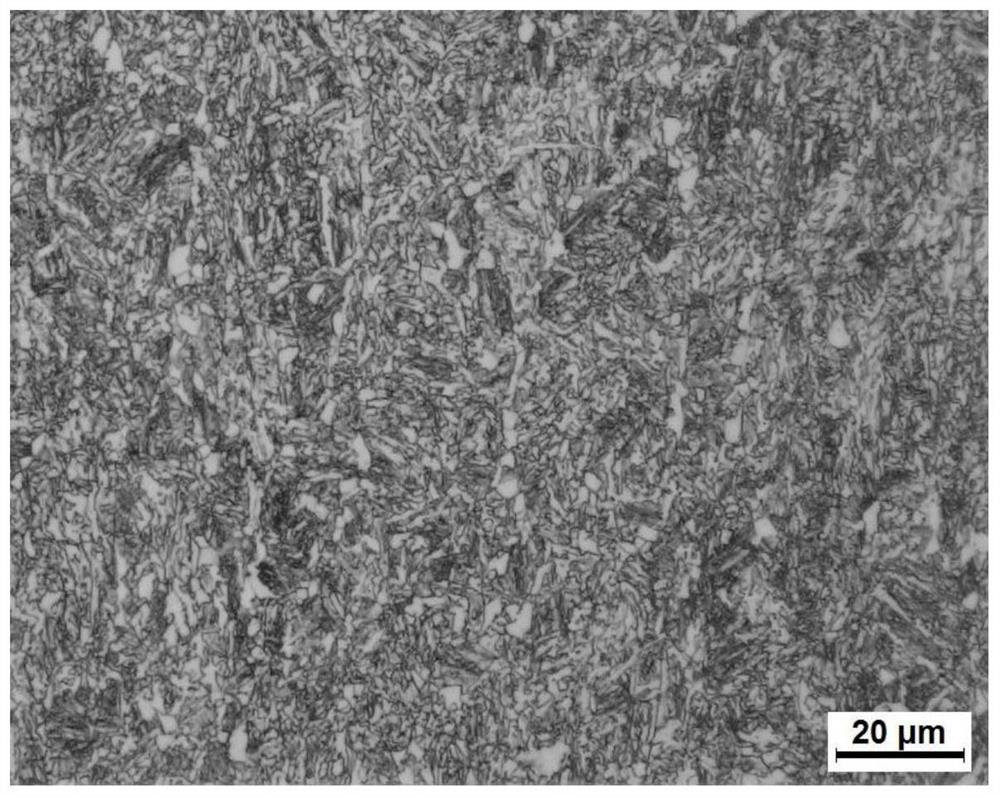

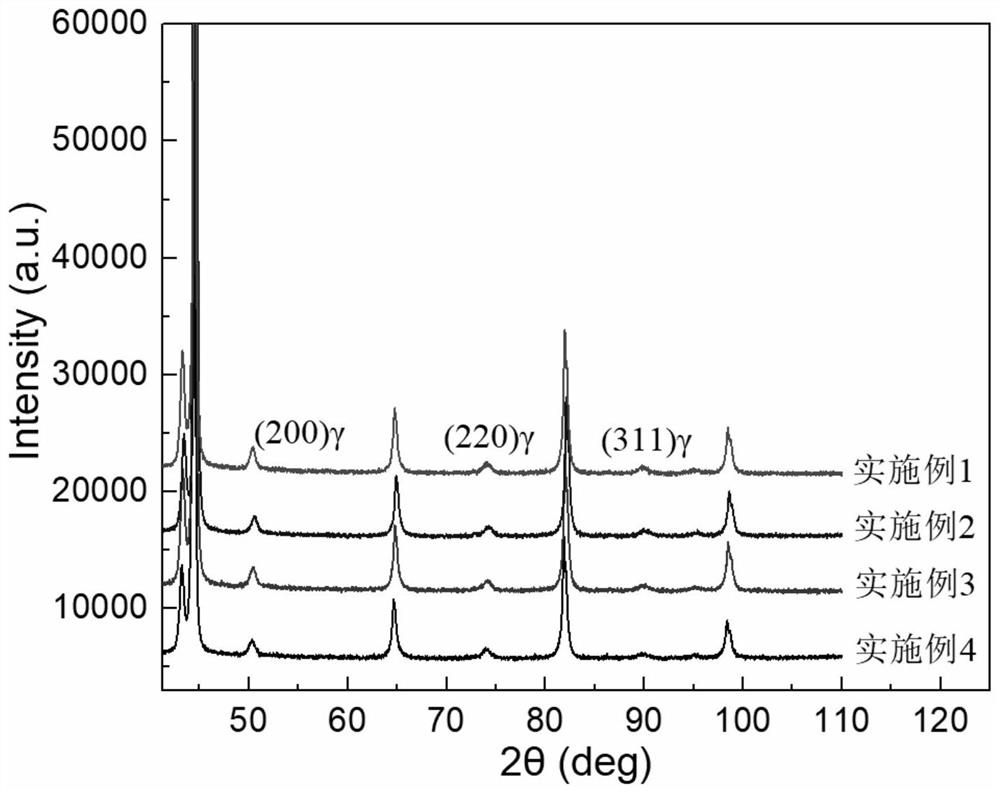

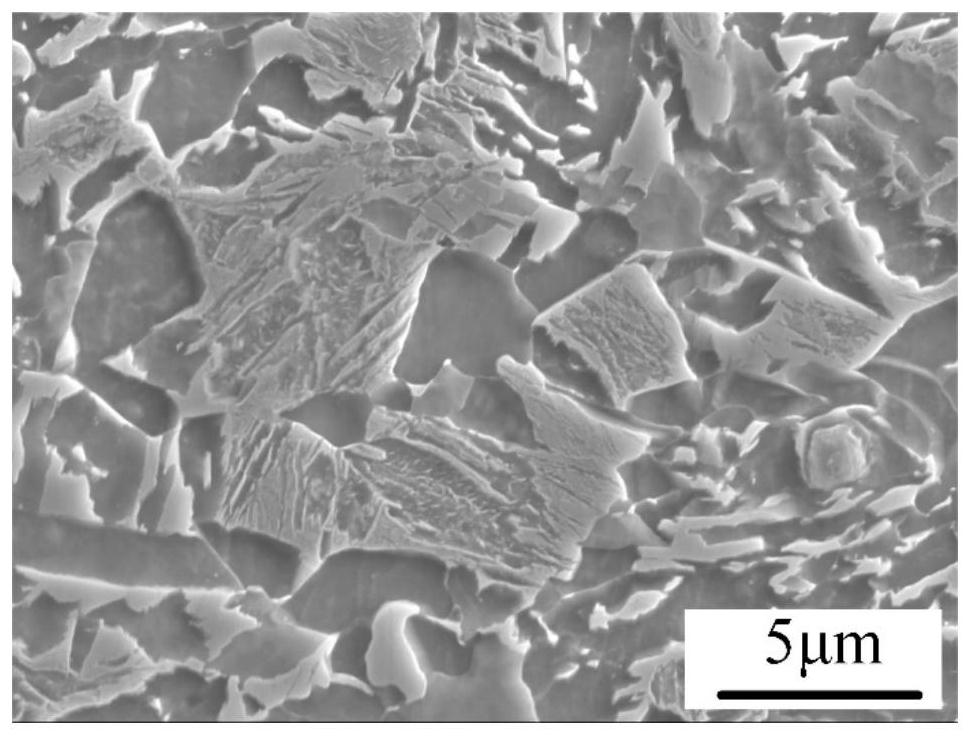

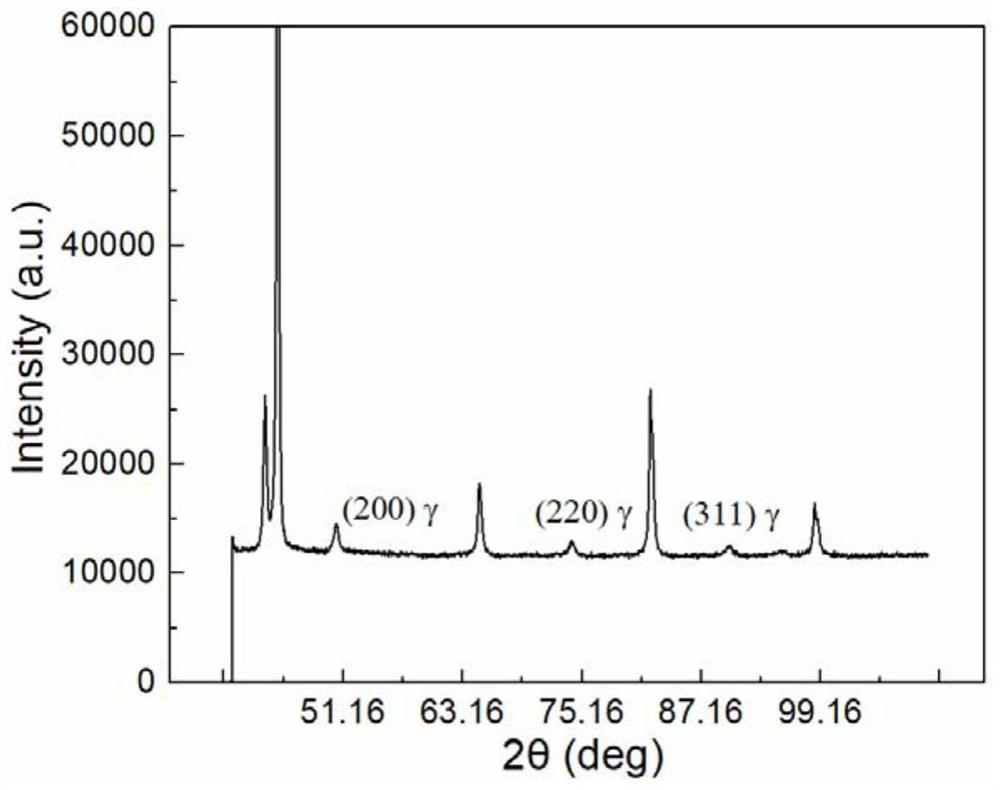

Q-and-P organized hot rolled Fe-Mn-Al-C steel obtained by quenching to bainite zone and manufacturing method

ActiveCN109554622AImprove surface qualityAvoid tissue performance variance and board shape issuesQuenchingPhase transition kinetics

The invention belongs to the technical field of steel alloy materials, in particular to Q-and-P organized hot rolled Fe-Mn-Al-C steel obtained by quenching to a bainite zone and a manufacturing method. The hot rolled Fe-Mn-Al-C steel is prepared from the chemical components in percentage by weight: 0.22%-0.25% of C, 2.8%-3.2% of Mn, 1.8%-2.2% of Al, and the balance of Fe. The phase change dynamicsis controlled by composition design, experimental steel is cooled above an Ms temperature, sufficient bainite phase change is avoided when the steel is cooled slowly afterwards, and a structure withmartensite / bainite being as a matrix is obtained. The experimental steel is air-cooled to 500-550 DEG C after controlled rolling is carried out, then furnace cooling is carried out to the room temperature, finally, a complex phase Q-and-P structure of a small amount of ferrite, martensite / bainite and retained austenite is obtained, the tensile strength is more than 1050MPa, and the elongation is more than 20%. Thus, the difficult problem of low temperature quenching of the Q-and-P steel is not prone to controlling is solved.

Owner:NORTHEASTERN UNIV

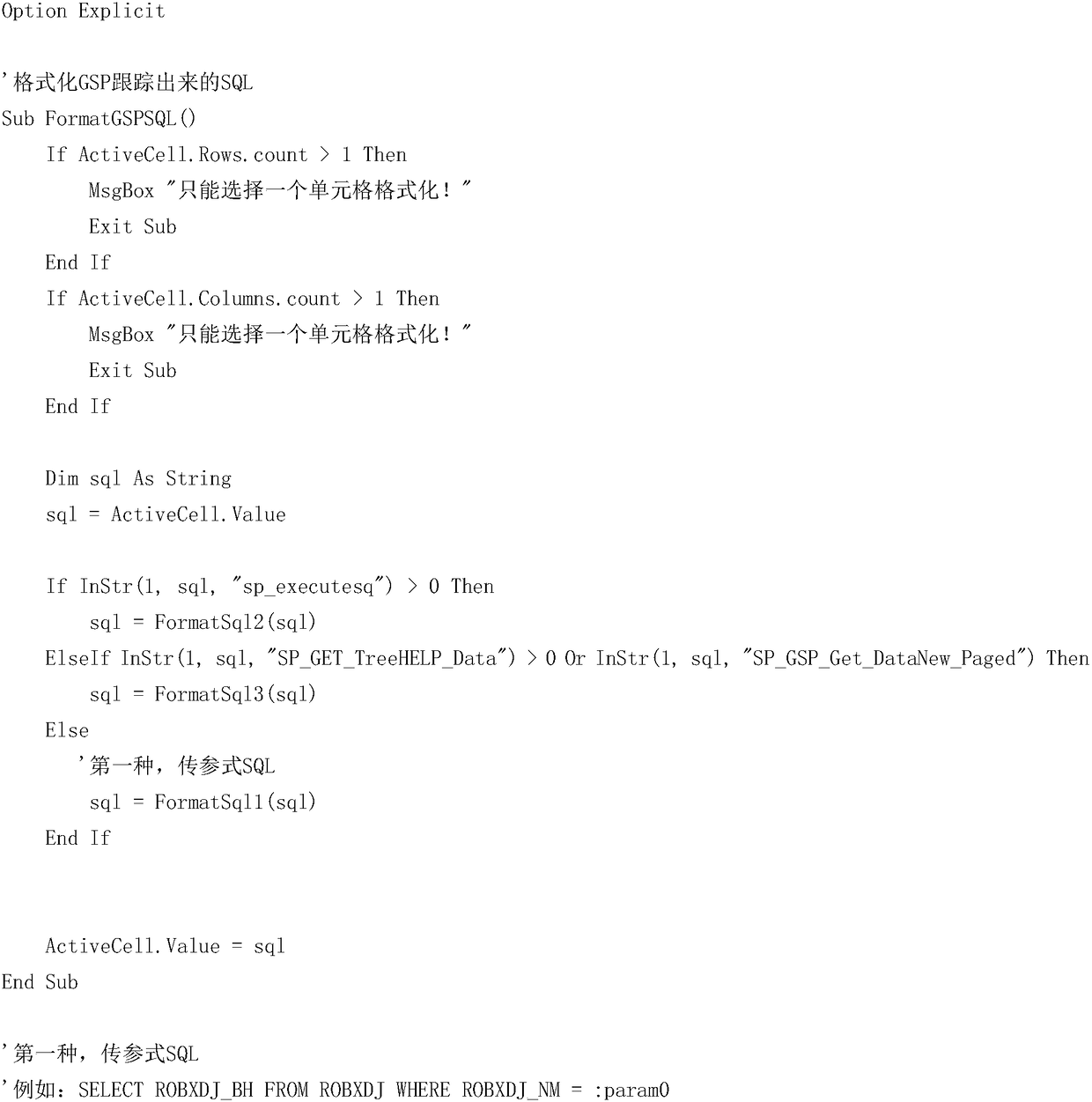

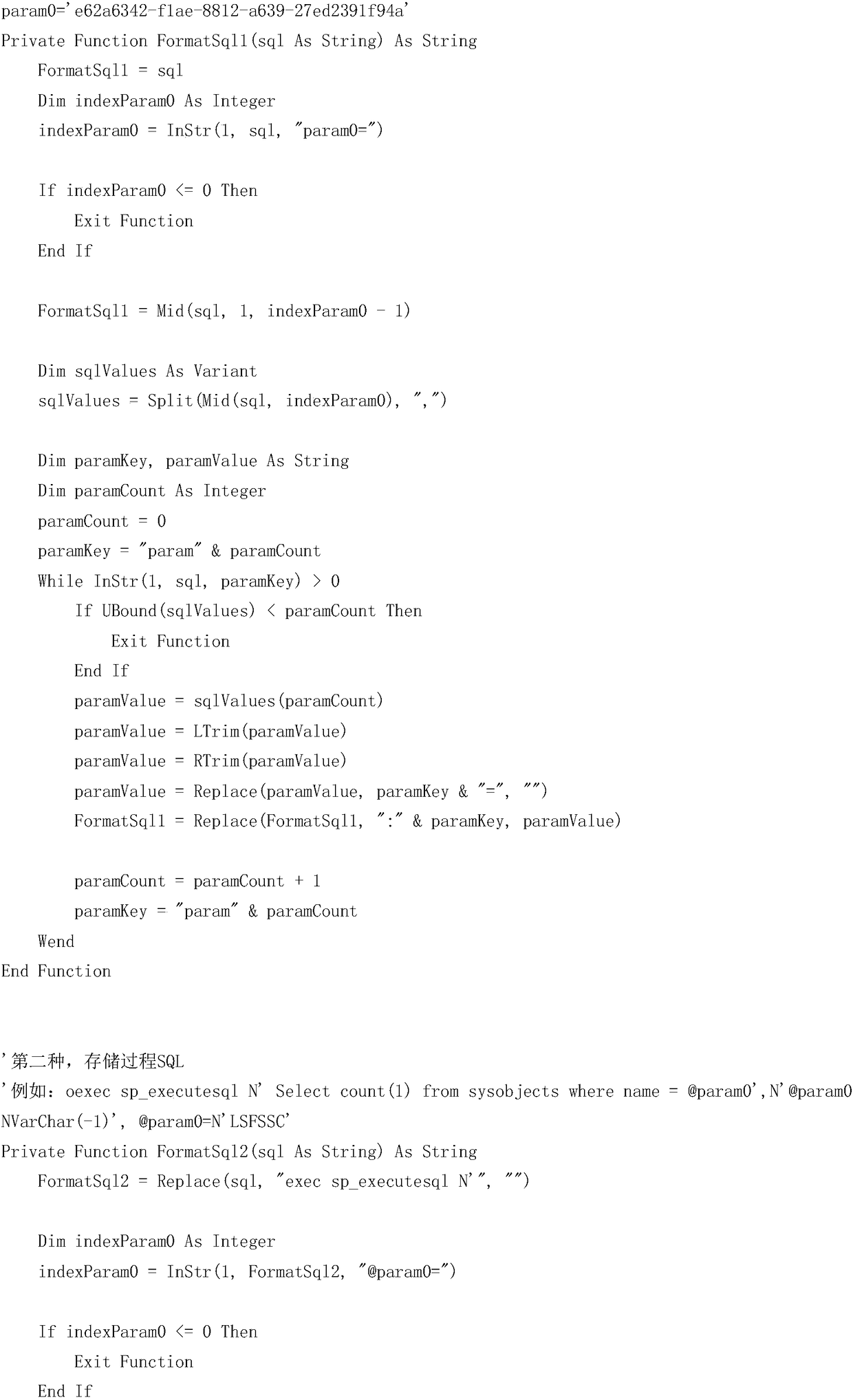

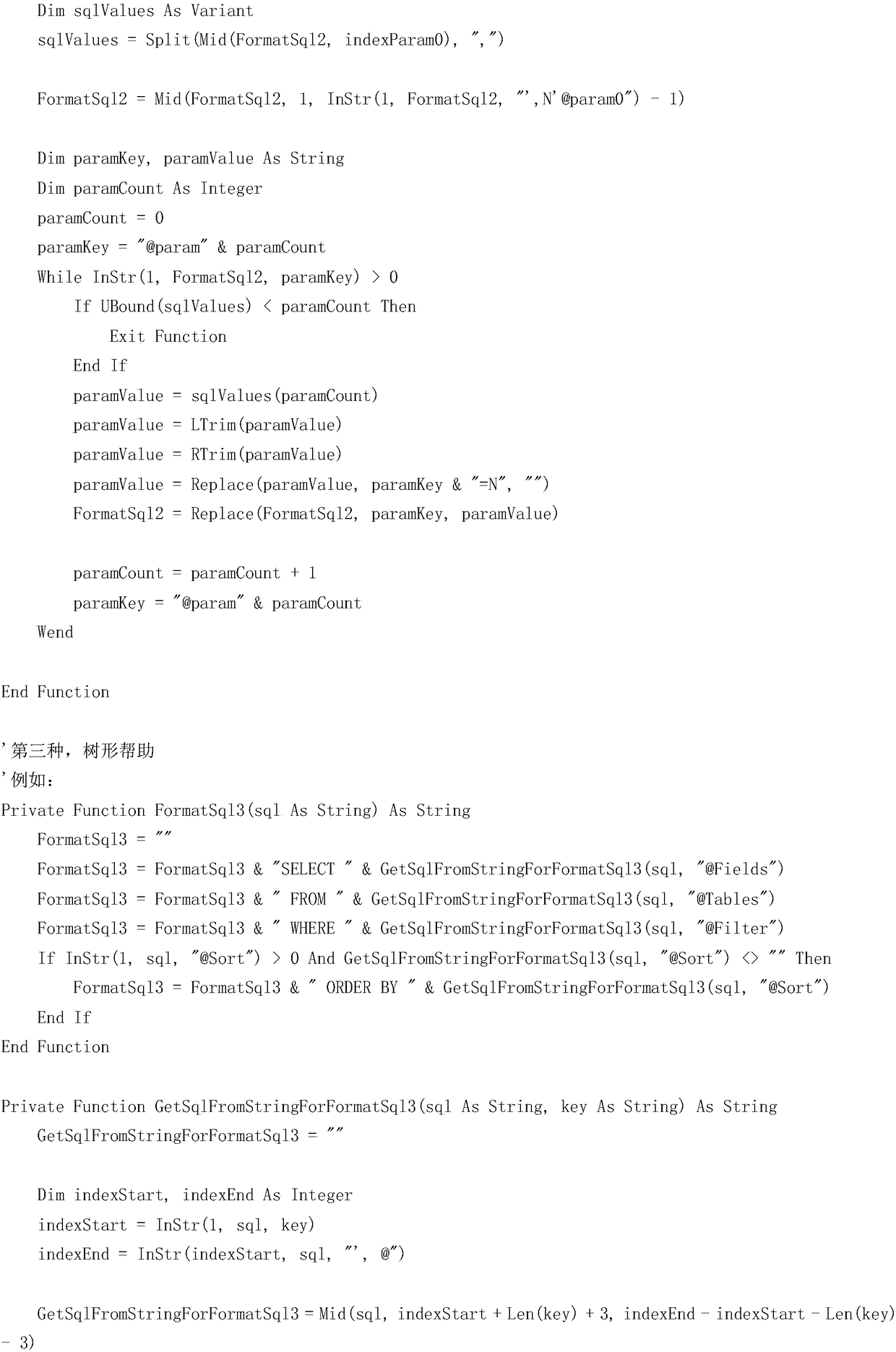

Implementation method for automatically converting and executing parameterized SQL based on Excel

InactiveCN108664236AImprove maintenance efficiencyReduce complicated stepsProgramming languages/paradigmsSpecial data processing applicationsSQLHuman language

The invention provides an implementation method for automatically converting and executing parameterized SQL based on Excel, belongs to technical field of computer applications, the performance of a automatic conversion SQL can help developers to execute the SQL language quickly, convert basic parameterized SQL, stored process SQL, tree help, etc, tracked by the event tracker into executable SQL quickly, and can connect the database to execute directly and check result. Project research and development and maintenance efficiency. The invention is good in use effect in EPR system project maintenance, and is also suitable for other systems.

Owner:SHANDONG INSPUR GENESOFT INFORMATION TECH CO LTD

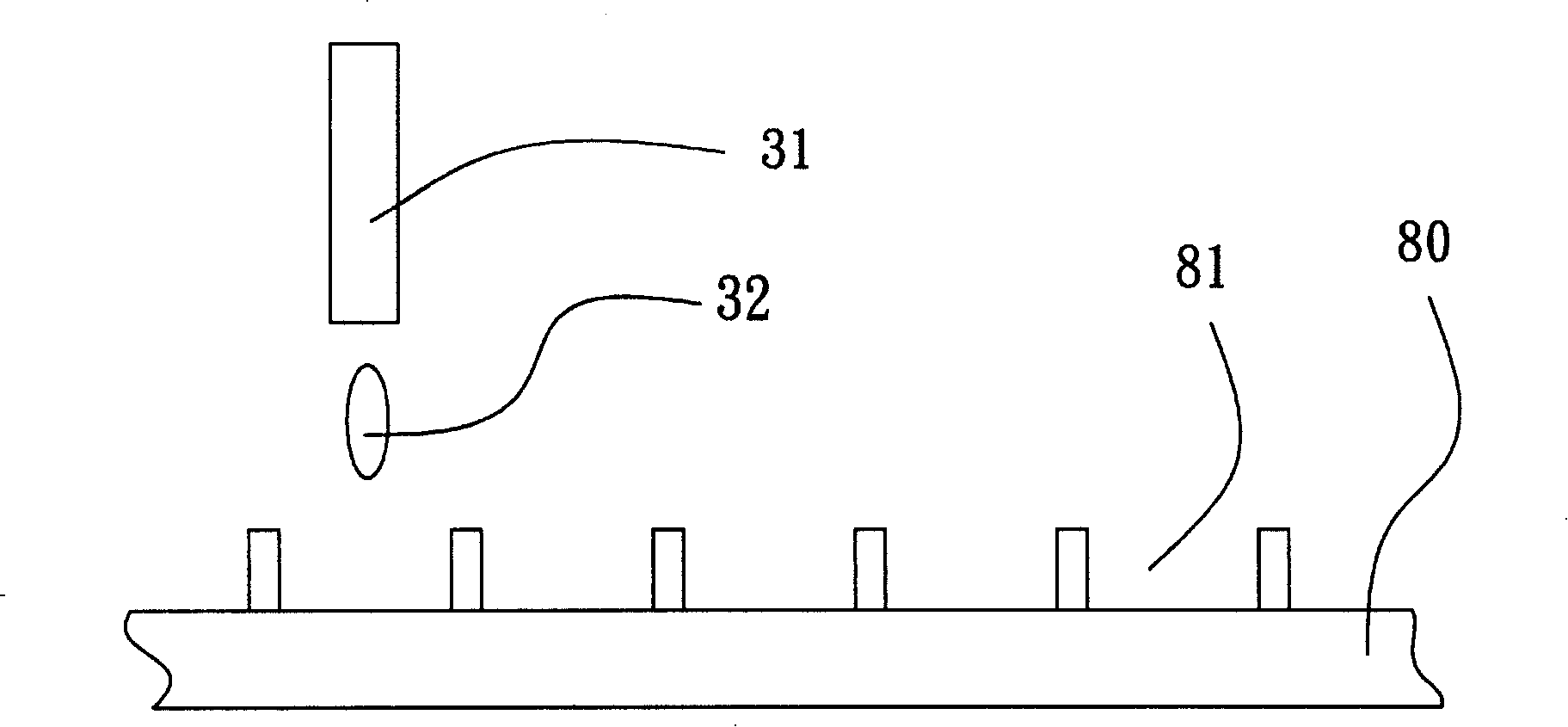

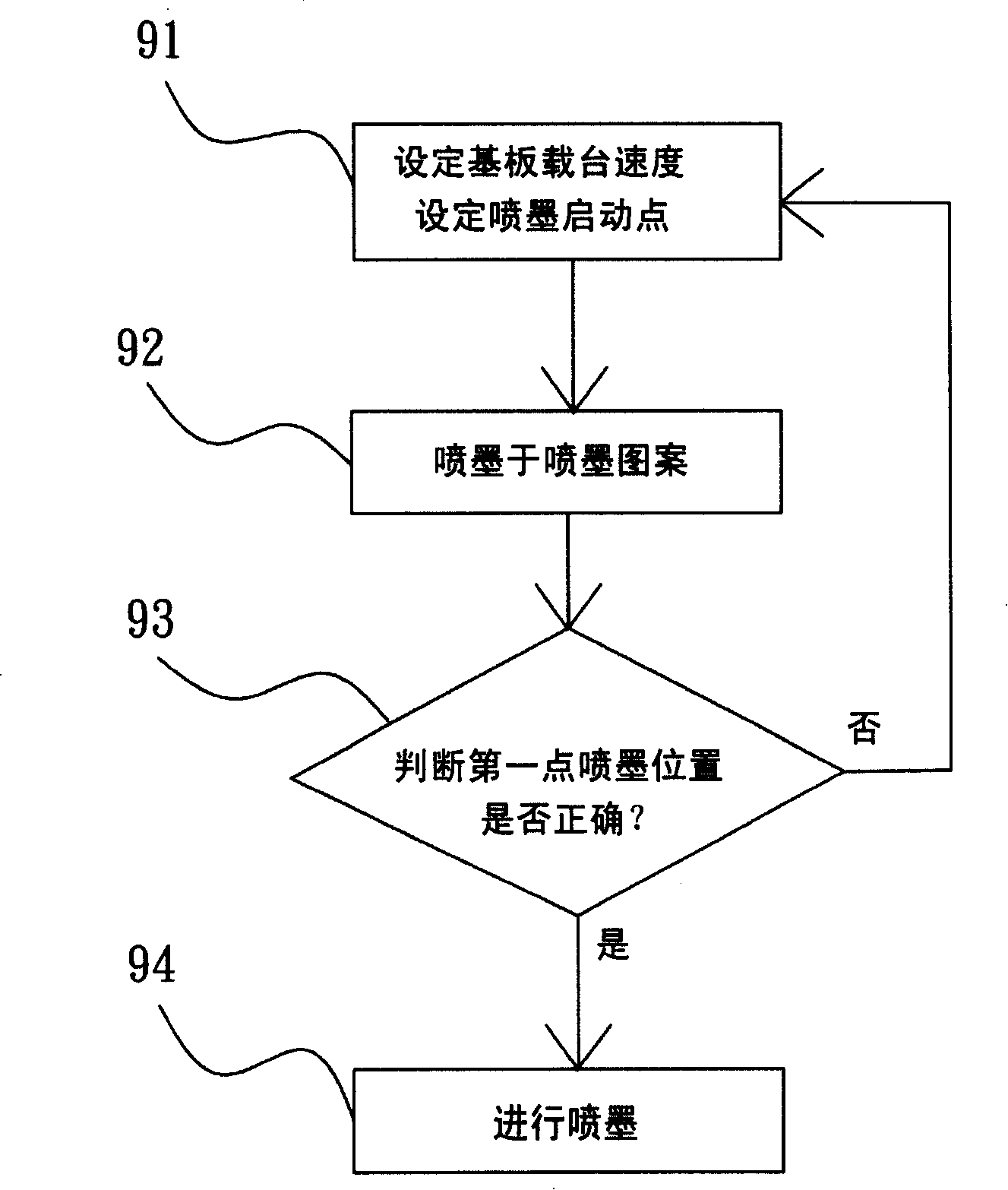

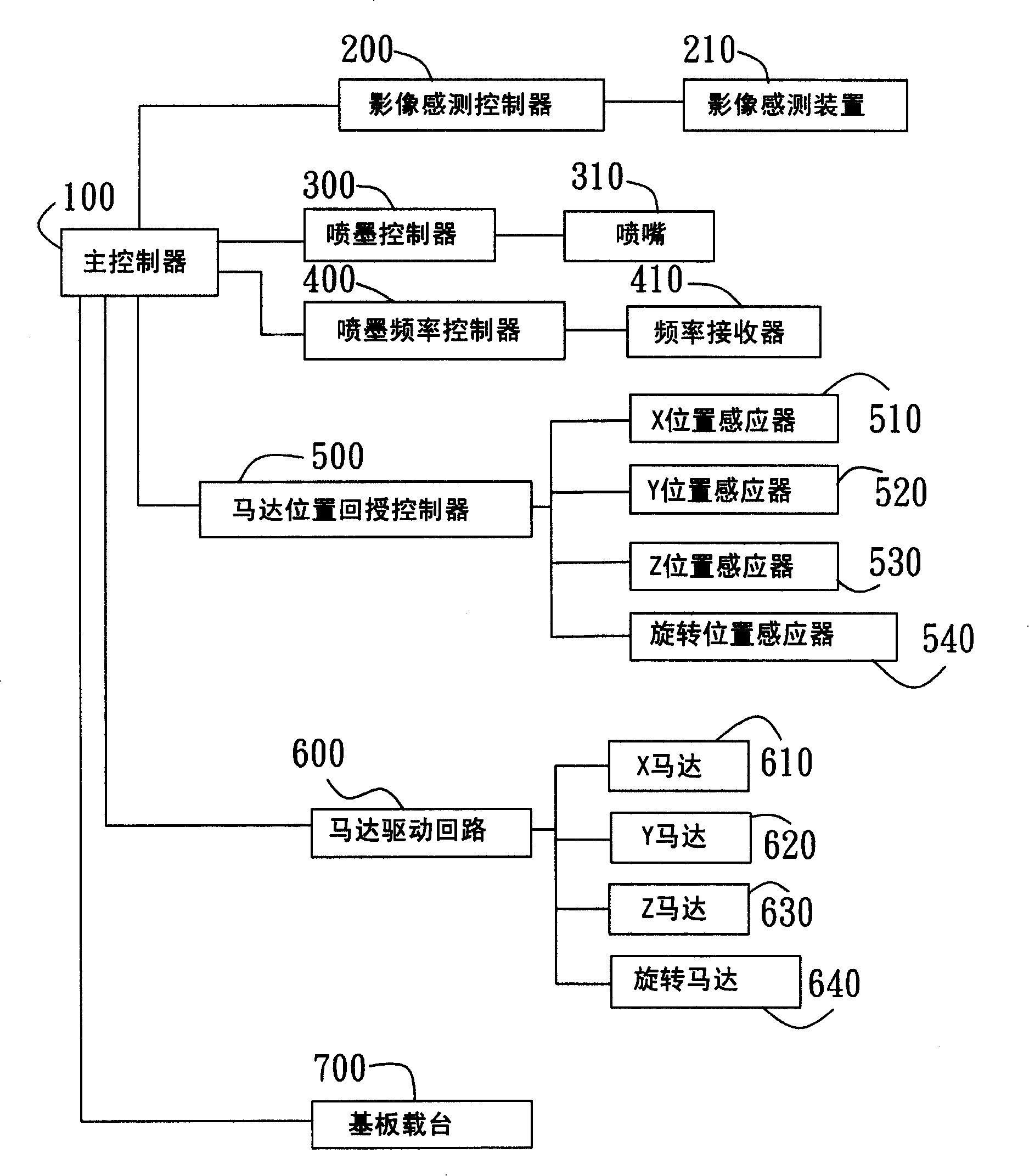

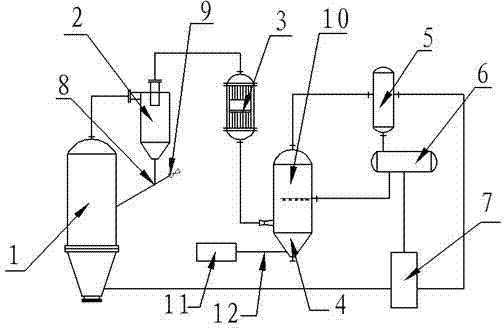

Ink-jet apparatus and method

The invention relates to an ink jet device, which comprises a main controller, an image sensing controller arranged between the main controller and an image sensing device, which is used for controlling the image sensing device, an ink jet controller arranged between the main controller and a nozzle which is used for controlling the nozzle, an ink jet frequency controller arranged between the main controller and a frequency receiver which is used for controlling the frequency receiver, a substrate loading platform connected with the main controller which is used for loading the substrate, a motor position back coupling controller comprising a plurality of location inductors, arranged between the main controller and the location inductors, which is used for calculating the position of the substrate loading platform and the adjustment amplitude of the rotation angle and a motor driving loop which comprises a plurality of motors corresponding with the location inductors is arranged between the main controller and the motor, which is used for controlling the location and the rotation angle of the substrate loading platform.

Owner:CHUNGHWA PICTURE TUBES LTD

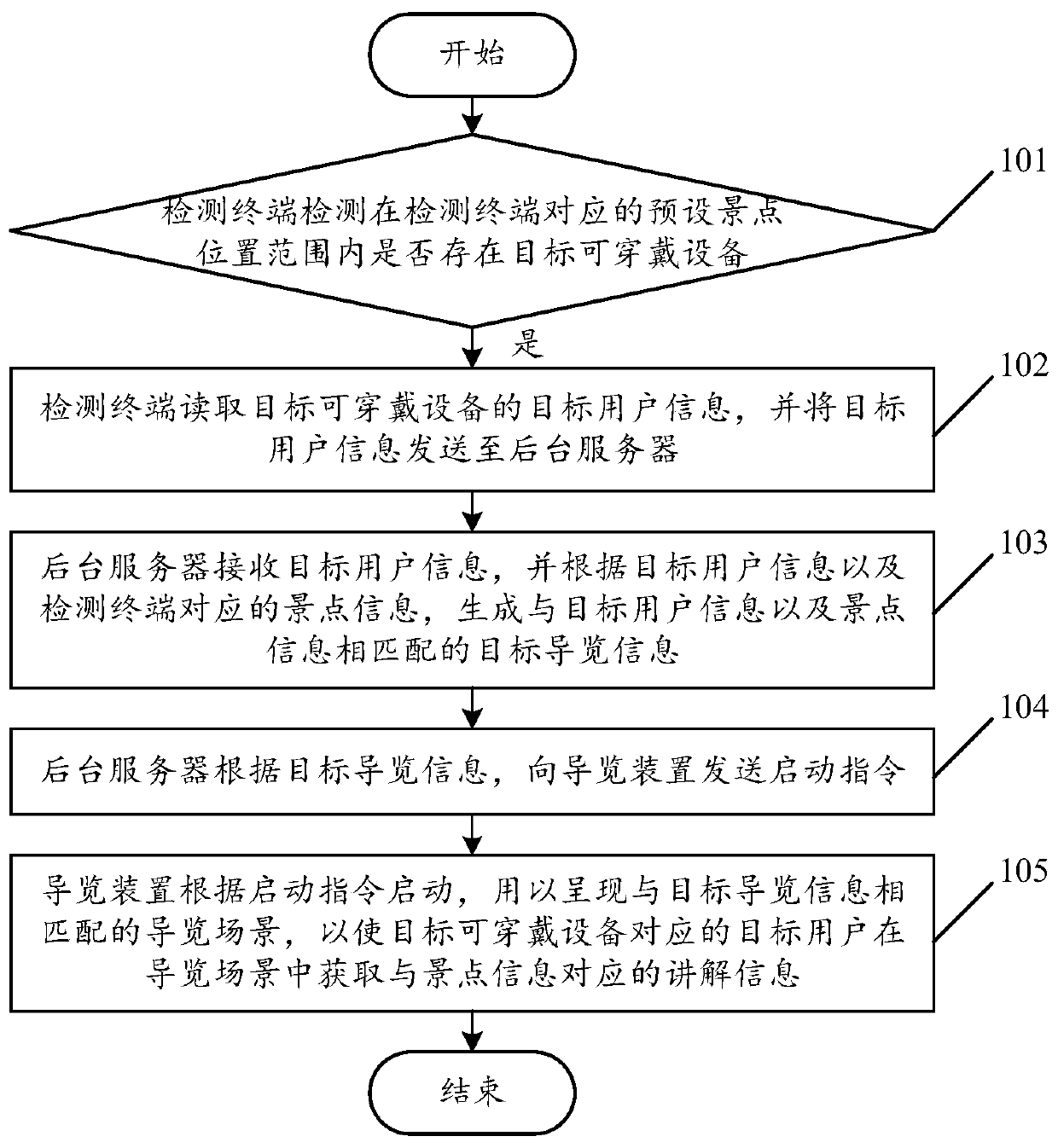

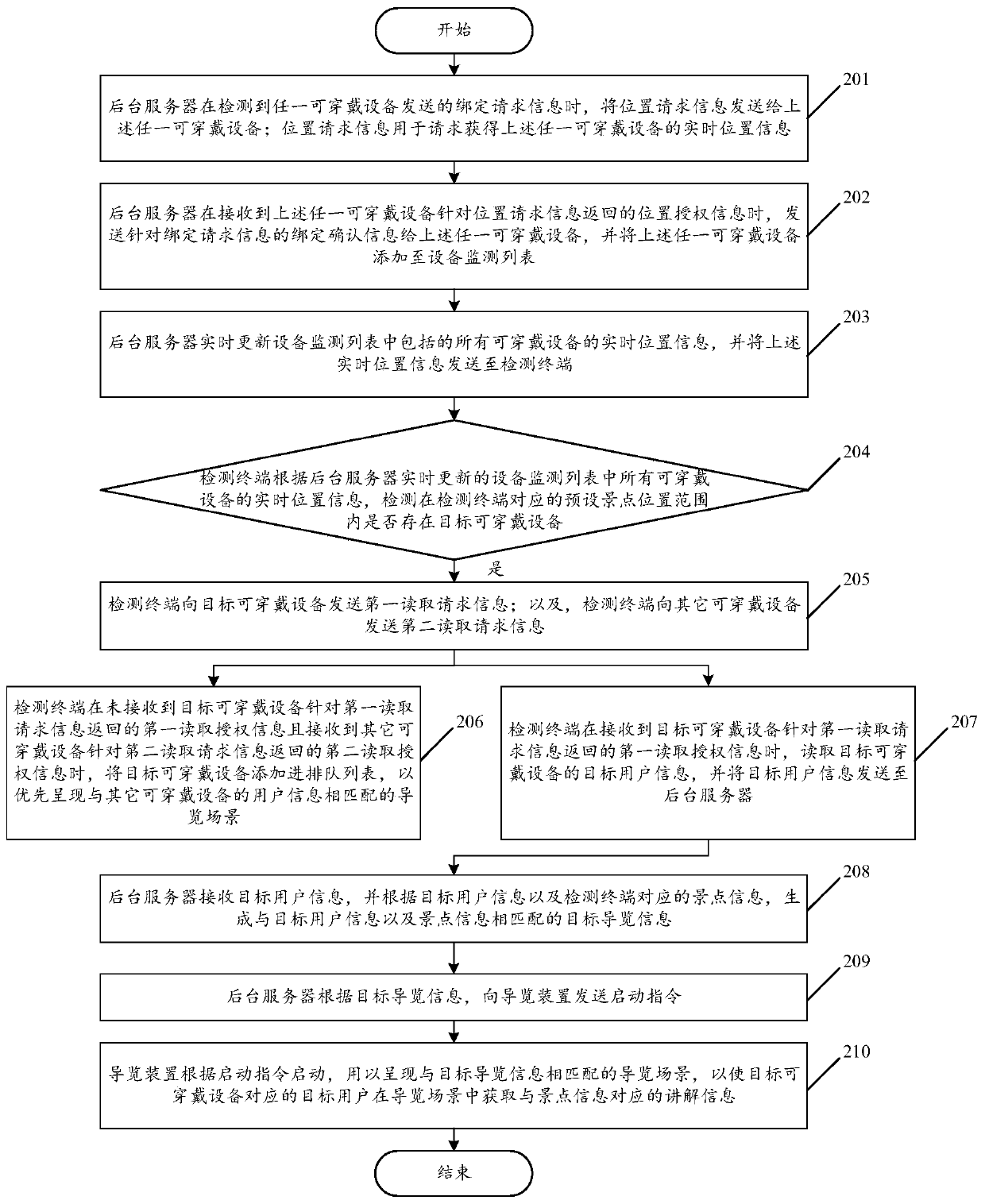

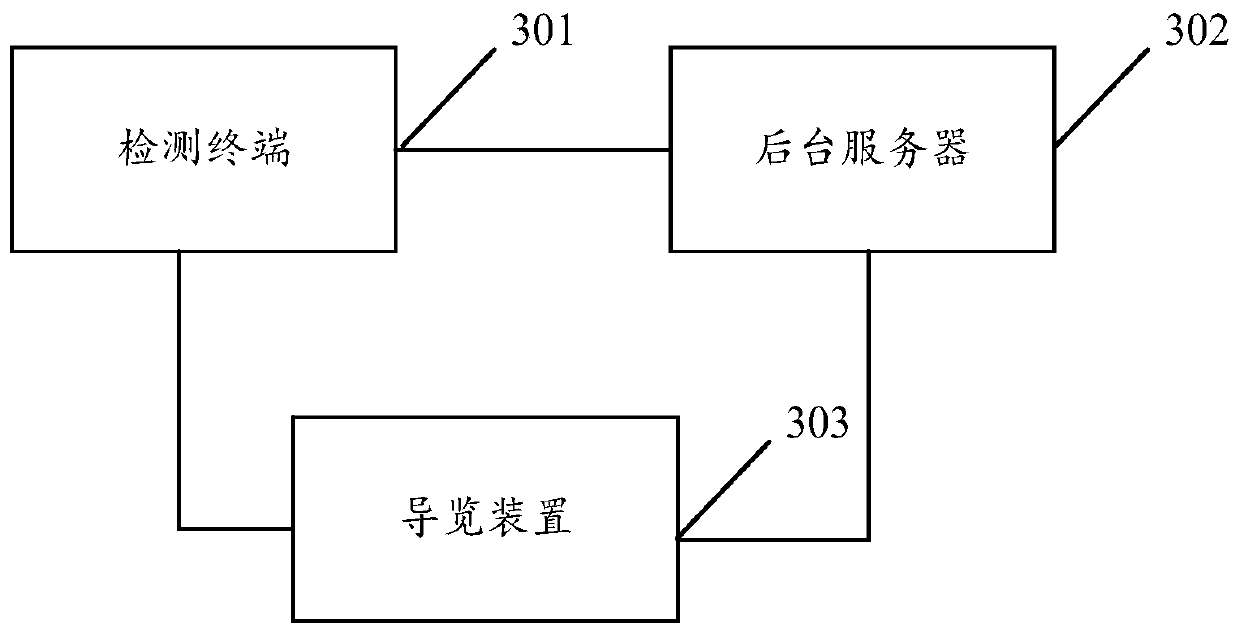

An intelligent navigation system and method based on wearable equipment

InactiveCN109712034AHigh degree of intelligenceReduce complicated stepsDigital data information retrievalData processing applicationsComputer terminalNavigation system

The embodiment of the invention relates to the technical field of scenic spot navigation, and discloses an intelligent navigation system and method based on wearable equipment, and the system comprises a detection terminal which is used for detecting whether target wearable equipment exists in a preset scenic spot position range corresponding to the detection terminal; if yes, target user information of the target wearable device is read, and the target user information is sent to a background server; the background server is used for generating target guide information matched with the targetuser information and the scenic spot information according to the target user information and the scenic spot information corresponding to the detection terminal; Sending a starting instruction to the navigation device according to the target navigation information; and the navigation device is used for starting according to the starting instruction and presenting a navigation scene matched withthe target navigation information, so that a target user corresponding to the target wearable device obtains the explanation information corresponding to the scenic spot information in the navigationscene. Therefore, by implementing the embodiment of the invention, an intelligent scenic area automatic guide service can be provided for tourists.

Owner:GUANGZHOU LEAFUN CULTURE SCI & TECH

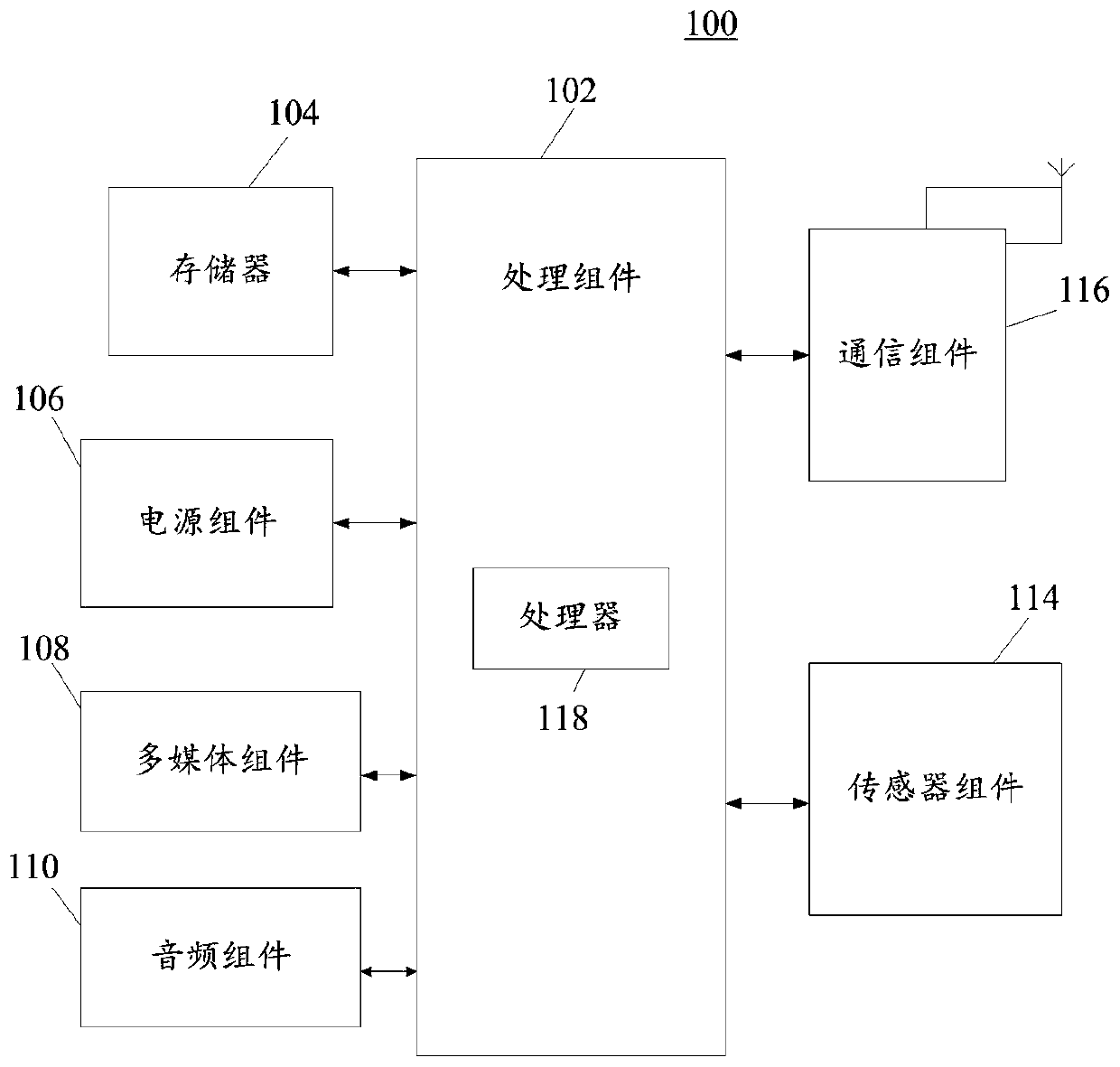

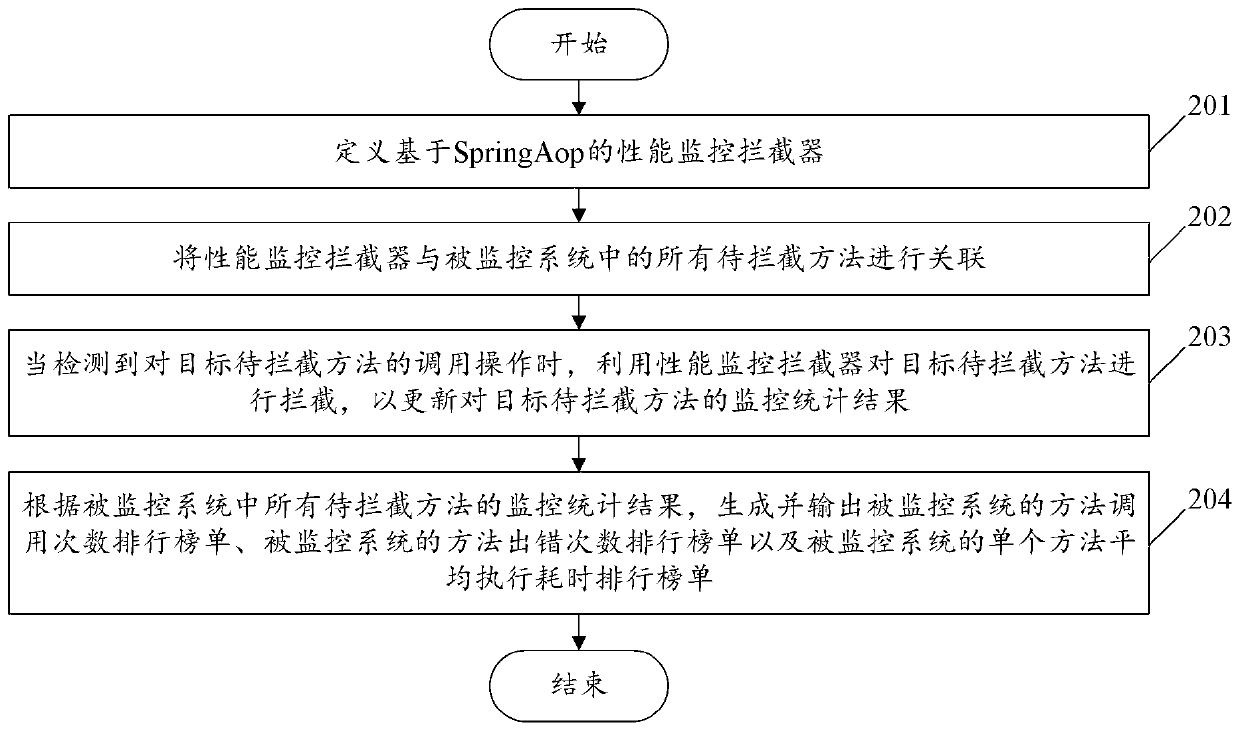

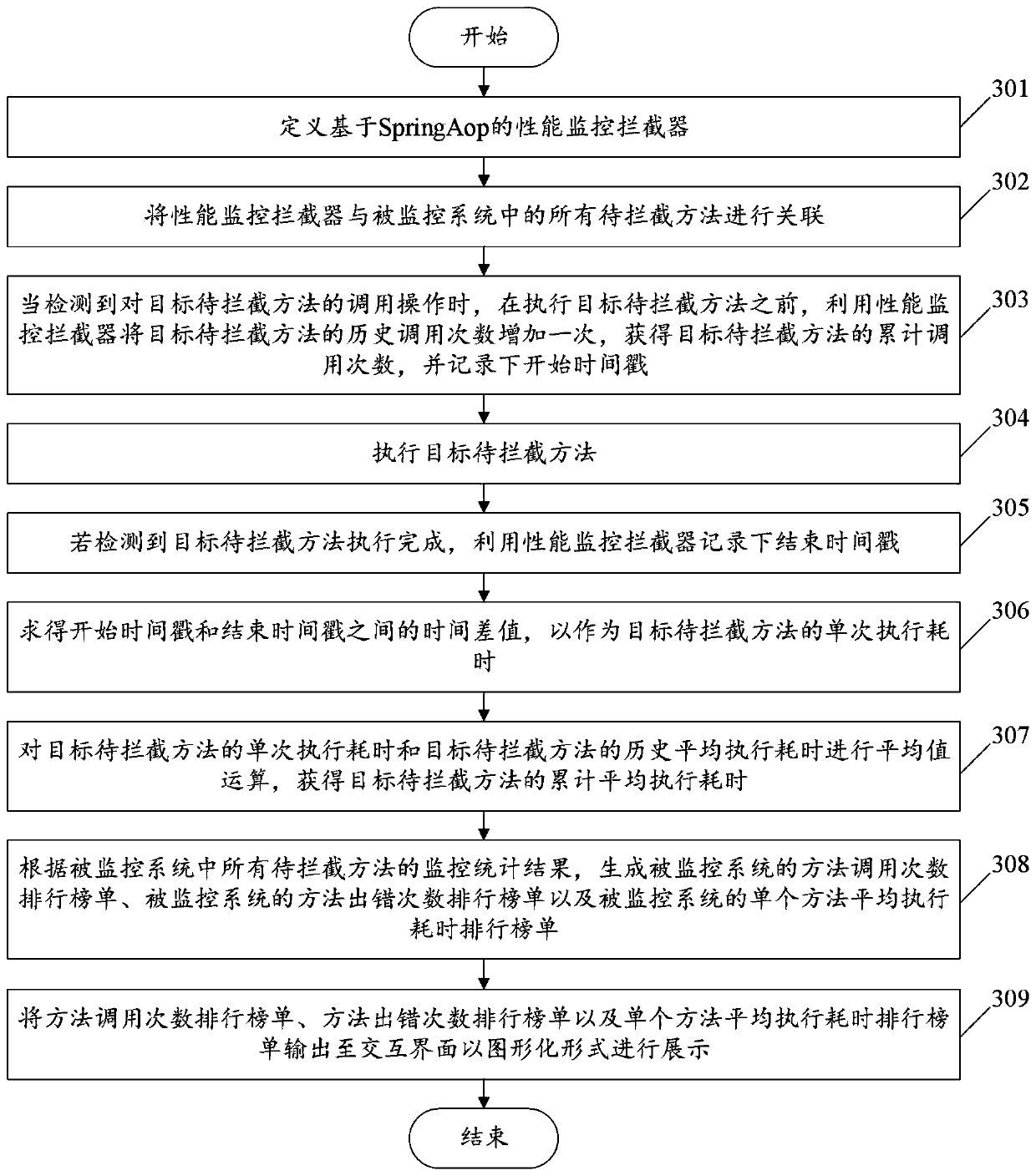

SpringAop-based system performance monitoring method and device, and electronic device

ActiveCN110362459AImprove comprehensivenessHigh degree of visualizationHardware monitoringRankingData monitoring

The invention relates to the technical field of system data monitoring, and discloses a SpringAop-based system performance monitoring method and devices, and an electronic device. The method comprisesthe following steps: defining a performance monitoring interceptor based on Spring Aop; associating the performance monitoring interceptor with all to-be-intercepted methods in the monitored system;when a calling operation on the target to-be-intercepted method is detected, intercepting the target to-be-intercepted method by utilizing a performance monitoring interceptor so as to update a monitoring statistical result on the target to-be-intercepted method; wherein the target to-be-intercepted method is any to-be-intercepted method in the monitored system; and according to the monitoring statistical results of all the to-be-intercepted methods in the monitored system, generating and outputting a method calling frequency ranking list, a method error frequency ranking list and a single method average execution time-consuming ranking list of the monitored system. By implementing the method, the system performance monitoring efficiency can be improved.

Owner:CHINA PING AN LIFE INSURANCE CO LTD

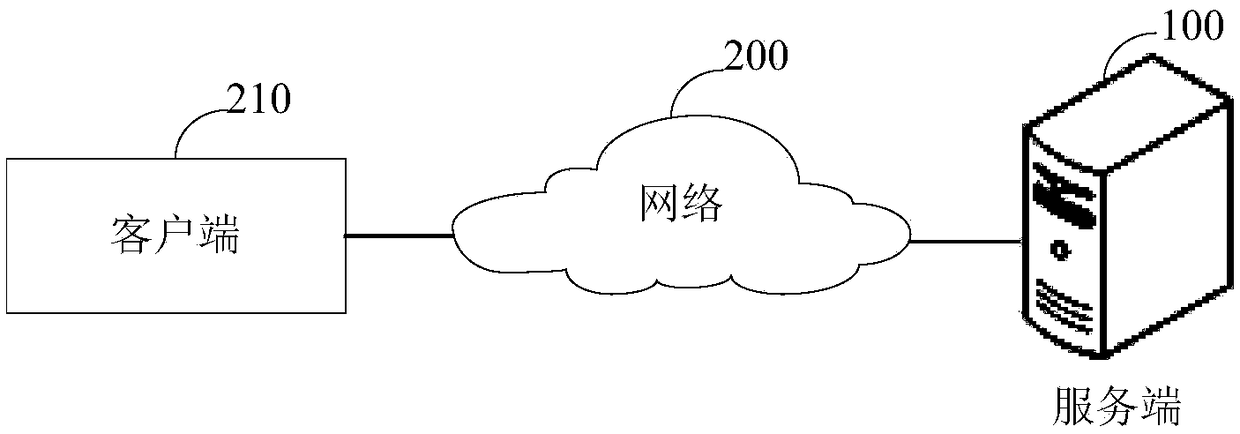

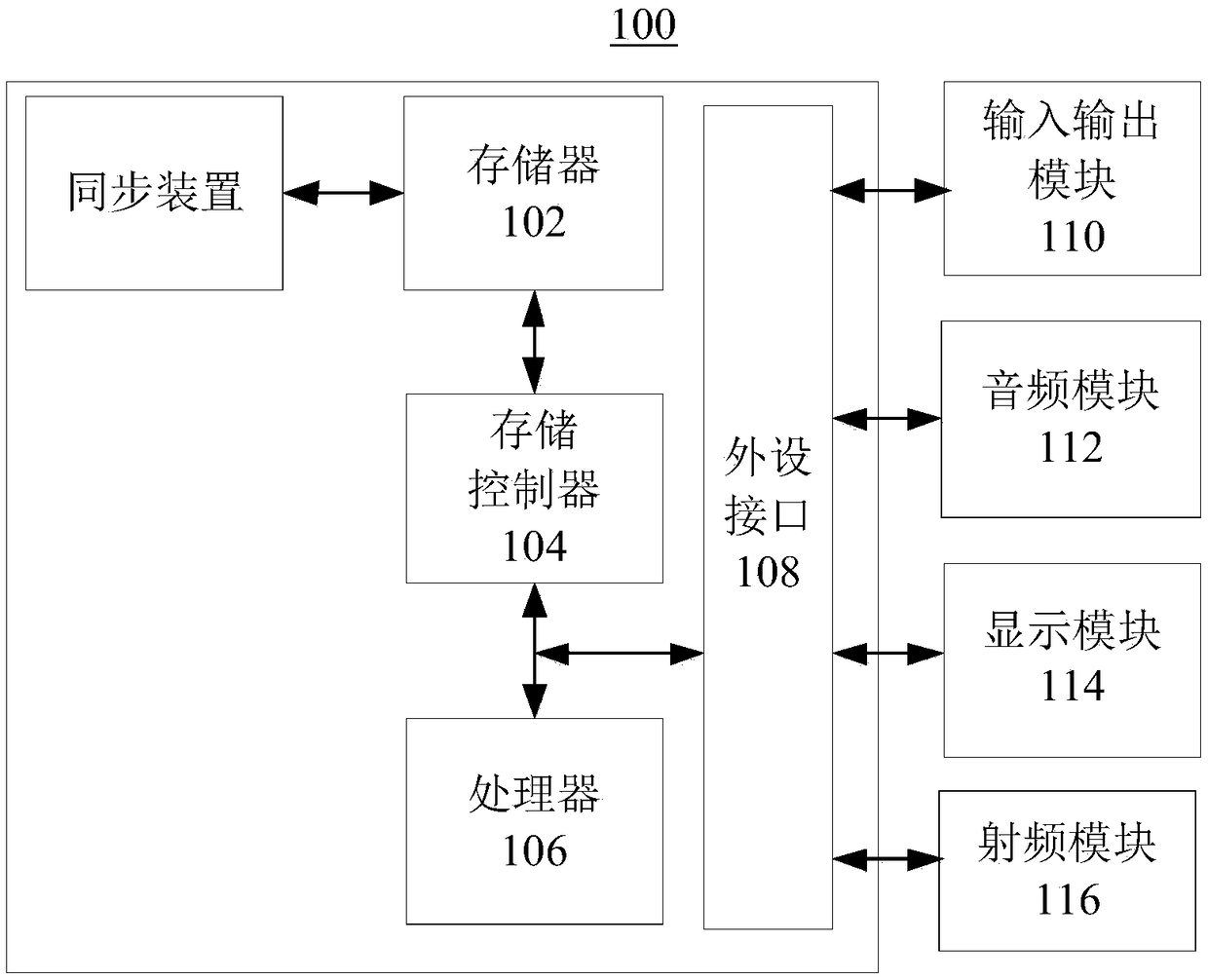

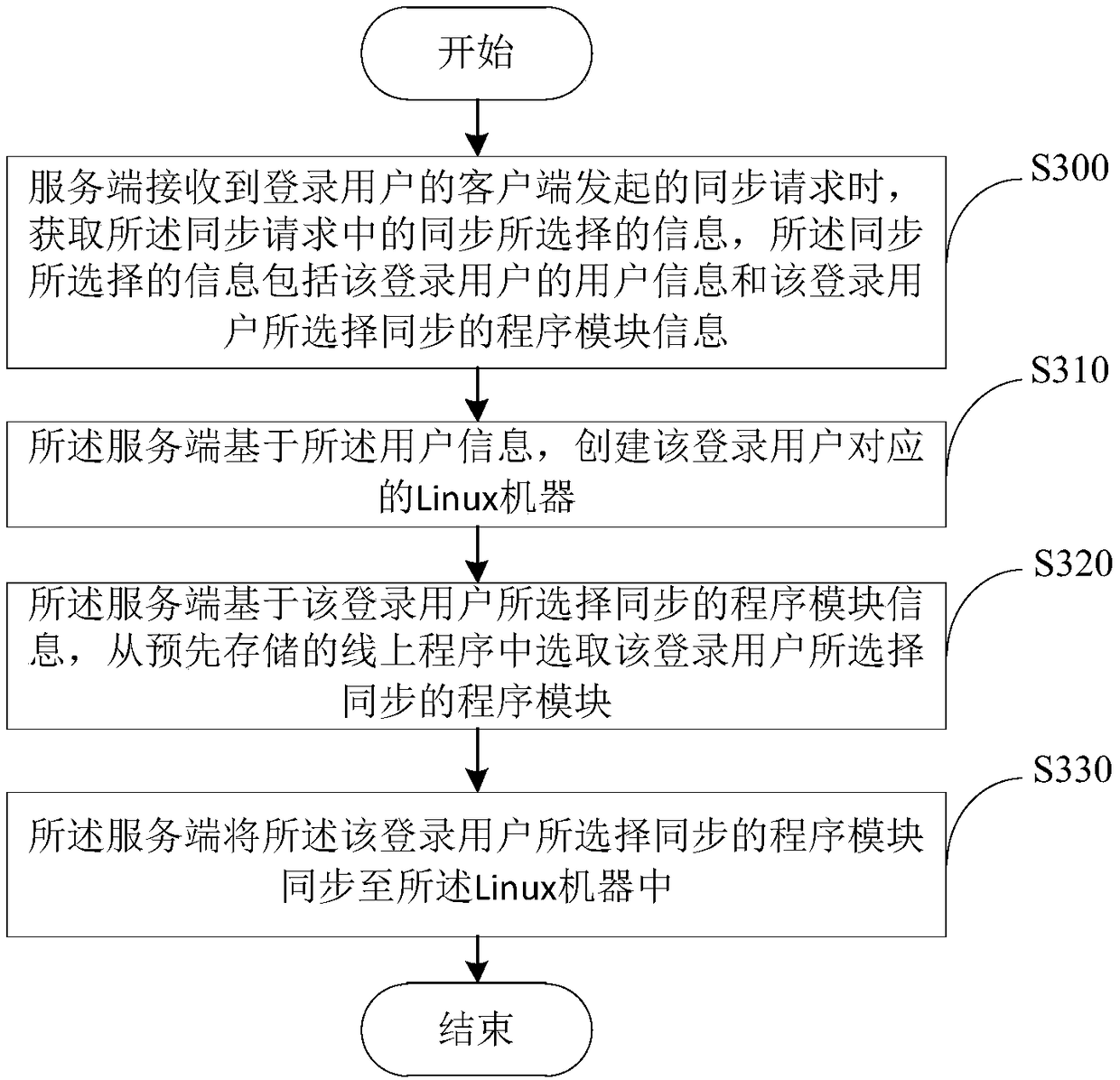

Synchronization method and device and computer readable storage medium

The embodiment of the invention provides a synchronization method and device and a computer readable storage medium, and relates to the technical field of data processing. The method comprises the steps that while a server side receives a synchronization request issued by a client side of a login user, information selected by synchronization in the synchronization request is acquired, the information selected by the synchronization comprises user information of the login user and program module information of the synchronization selected by the login user, the server side establishes a Linux machine corresponding to the login user based on the user information, and selects a program module of the synchronization selected by the login user from pre-stored online programs based on the program module information of the synchronization selected by the login user; then the program module of the synchronization selected by the login user is synchronized into the Linux machine. The method achieves that the selected program module is synchronized and migrated to another machine by one key, thereby omitting miscellaneous steps of manually downloading the program module, improving the working efficiency and saving the time.

Owner:BEIJING SHUNFENG TONGCHENG TECH CO LTD

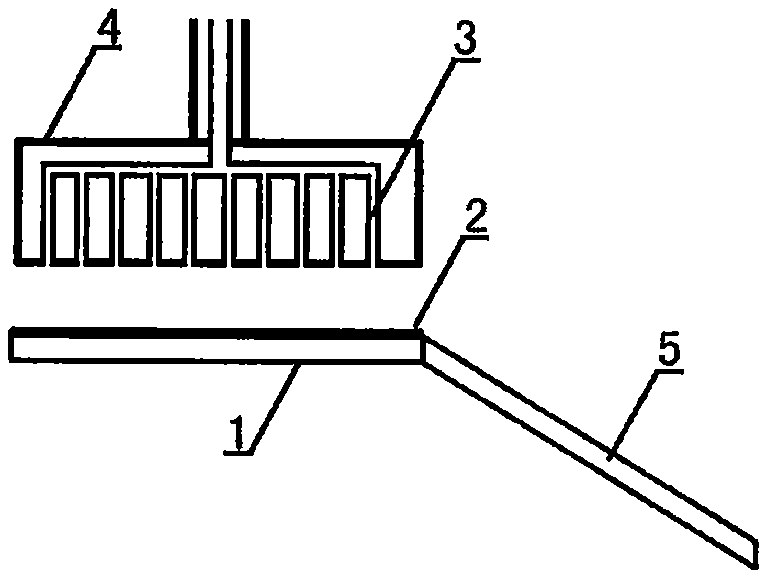

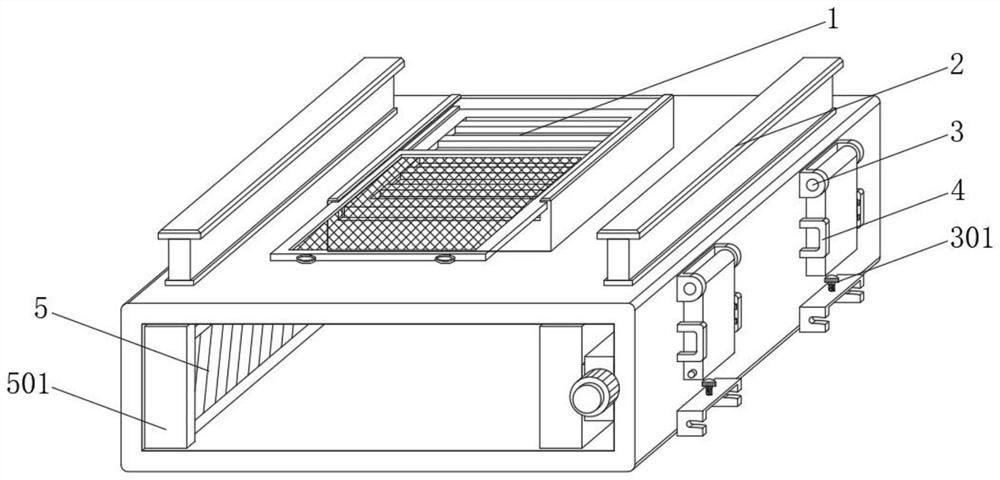

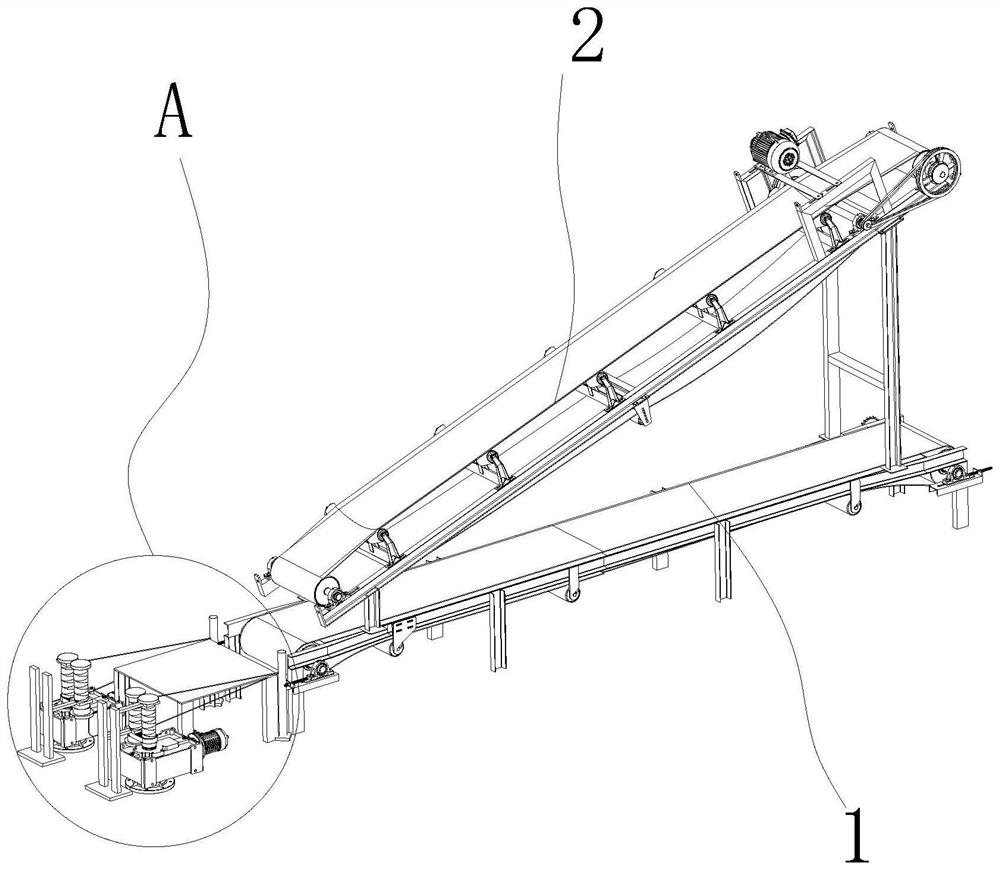

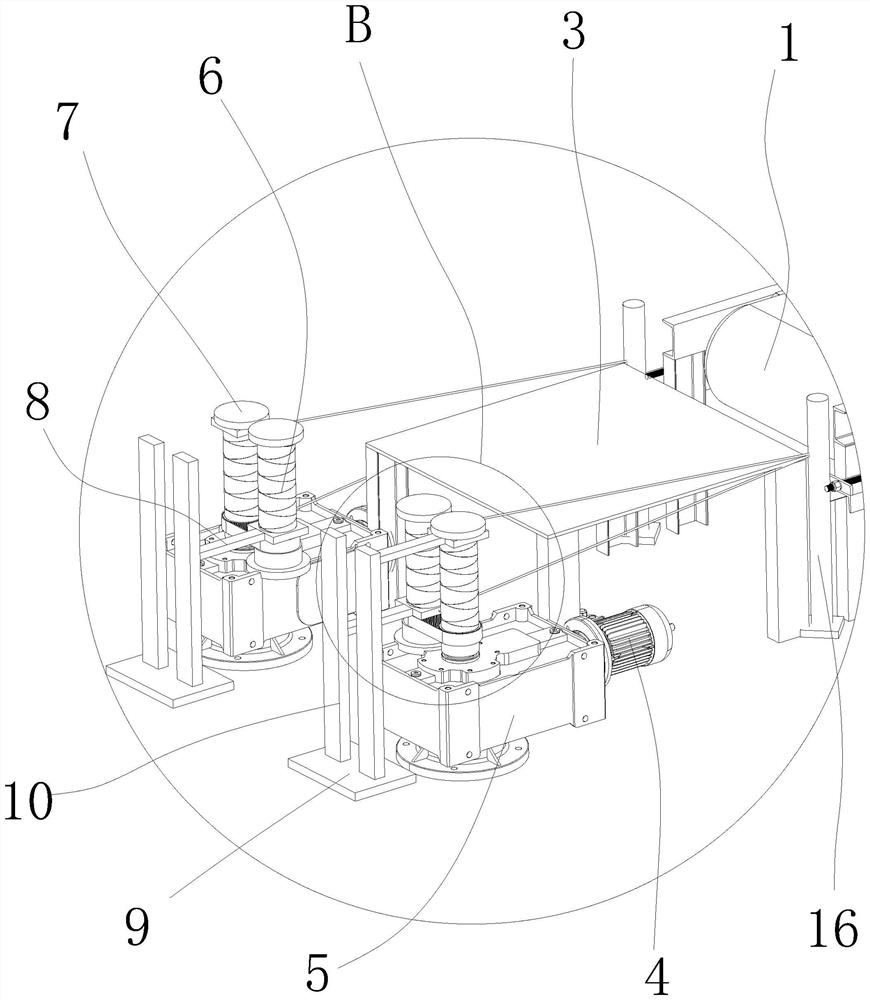

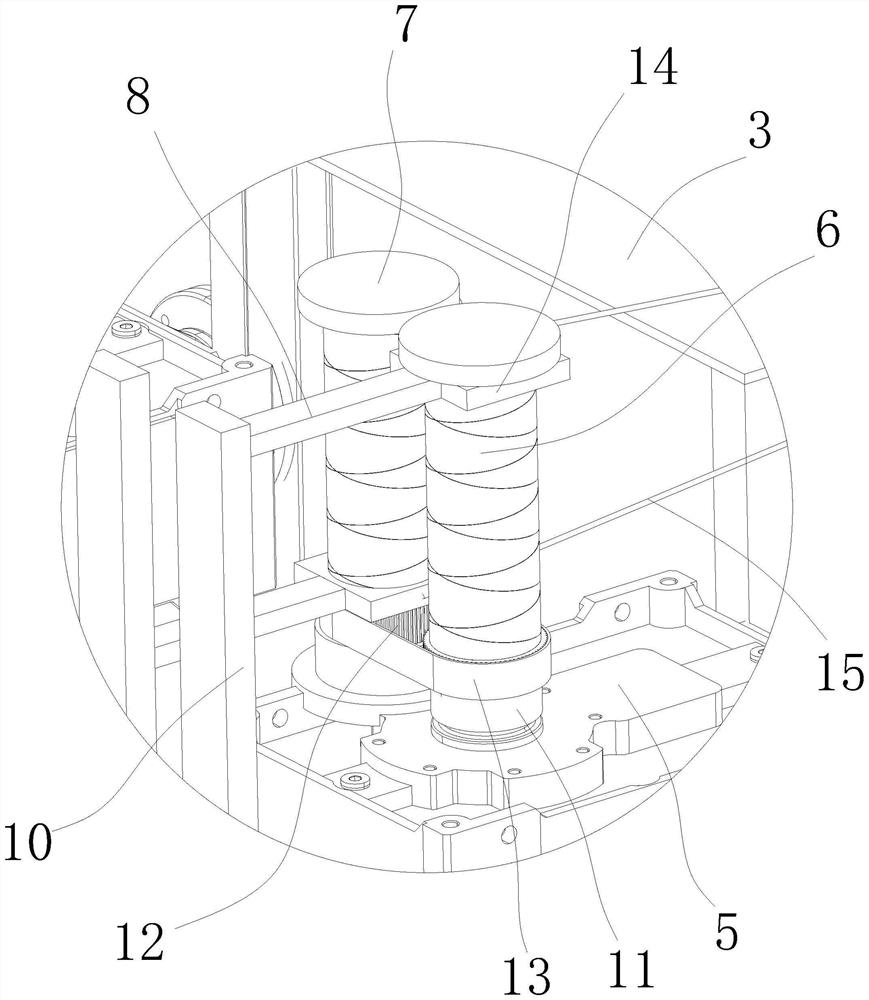

Spinning coloring drying device

InactiveCN107675383AUniform colorReduce complicated stepsLiquid/gas/vapor removalTextile treatment by pouringEngineeringMechanical engineering

A textile coloring and drying device, comprising an electric conveyor belt [1], an oily film [2] is set on the horizontal conveyor belt, which is close to the electric conveyor belt [1], and a plurality of capillary The coloring device [4] of the conduit [3] is provided with a heating plate [5] at the lower end of the inclined electric conveyor belt [1]; an electric conveyor belt [1] can drag the textile cloth in the left middle part of the whole device; Set oily film [2] to prevent the color from adhering to the conveyor belt and keep the conveyor belt clean; set multiple capillary tubes [3], which are arranged in parallel in the shader to make the color even; set the shader [4], above the conveyor belt, can be colored by lifting; setting a heating plate [5], can quickly dry after coloring; can evenly and quickly color, reduce the complicated steps in the traditional process, improve work efficiency and work quality.

Owner:宁夏昱科工业产品设计有限公司

Making method of acid ginger

InactiveCN106262300ADelicious and crispGreat tasteFood ingredient as taste affecting agentFood ingredient as mouthfeel improving agentTime rangeGingerol

The invention discloses a making method of acid ginger and belongs to the technical field of food processing. The making method includes the following steps that 1, glutinous rice is made; 2, acid grain fermentation is prepared, the glutinous rice and caky starter are mixed, and the mixture is put in a fermentation container; 3, acid grain fermentation is carried out, the fermentation temperature ranges from 30 DEG C to 40 DEG C, and the fermentation time ranges from 2 days to 3 days; 4, acid grain processing is carried out, and an acid grain semi-finished product is put in boiling water to be boiled for 3-5 min; 5, tender ginger is prepared; 6, the acid ginger is made, acid grains and the tender ginger are put in an acid jar according to the mass ratio of 1:(2-3), and the acid ginger is made 10-15 days later. The making method of the acid ginger is easy to operate and easy to achieve on production. The acid ginger is made from the acid grains fermented from glutinous rice, no additive is added, and the acid ginger is natural and free of danger; the made finished acid ginger is delicious, crispy and refreshing in taste and better in taste, the preservation time reaches one year or longer, and the seasonal problem of fresh ginger is solved.

Owner:赵青娇

Determination reagent for cholesterol in high density lipoprotein and preparing method thereof

ActiveCN100564539CImprove accuracyStrong specificityMaterial analysis by observing effect on chemical indicatorMicrobiological testing/measurementA lipoproteinActive agent

The invention relates to a reagent for measuring high-density lipoprotein cholesterol in serum and a preparation method. The technical problem to be solved by the present invention is to provide a method for preparing a reagent for measuring cholesterol in high-density lipoprotein and the improvement of the reagent. The reagent prepared by this method should have good specificity, simple and convenient detection, high test accuracy, and It can be detected on various types of automatic biochemical analyzers. The technical scheme is: the components of the reagent are as follows: A. high-affinity enzyme compound, which is obtained by the reaction of enzyme and compound, and the molar mixing ratio of the two components when reacting is 1:1-20:1; B. surfactant, The mixing ratio is 0.003-30% of the weight percentage of component A; C. appropriate amount of preservatives, stabilizers and chromogens. An appropriate amount of catalyst and anti-interference substances are also added to the reagent. The preparation method comprises the following steps: 1. compound activation; 2. enzyme dissolution; 3. mixed reaction; 4. configuration.

Owner:浙江伊利康生物技术有限公司

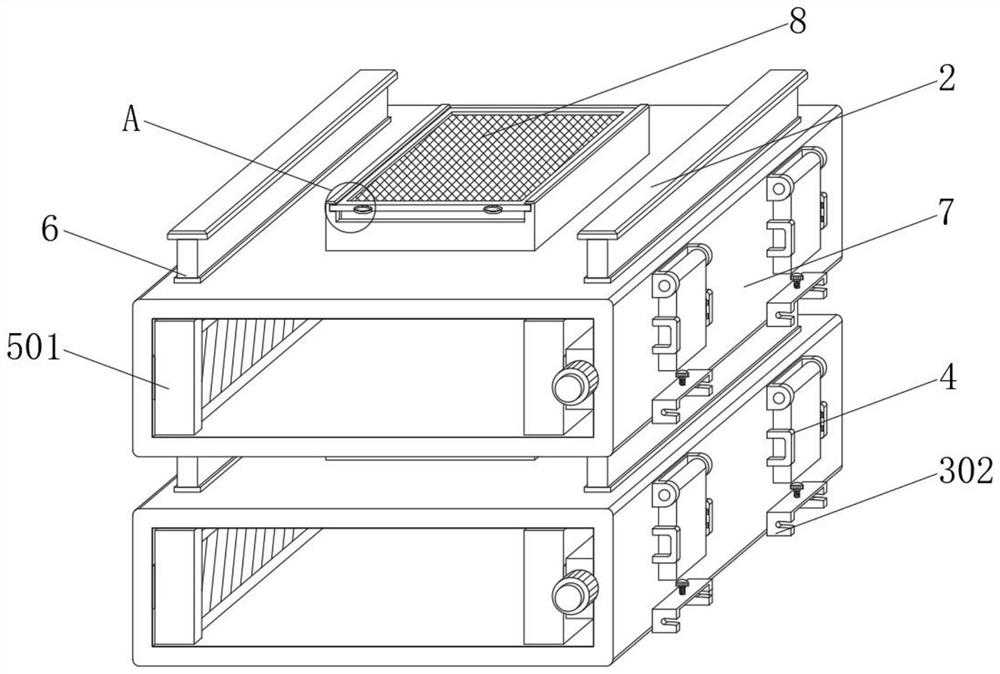

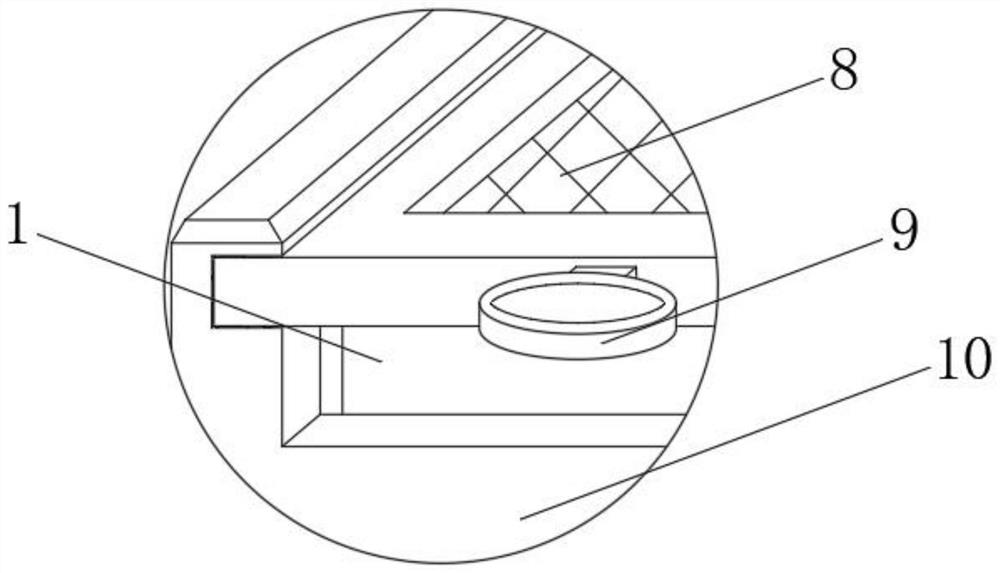

Modularized integrated multifunctional network security protection device

InactiveCN114745895AEasy to clean and reuseSpeed up the flowDispersed particle filtrationCasings/cabinets/drawers detailsEmbedded systemStructural engineering

The invention relates to the technical field of network security equipment protection, and discloses a modularized integrated multifunctional network security protection device, which comprises a shell, a fixed structure is arranged in the shell, and the fixed structure comprises a baffle plate, a limiting plate, a base, a knob, a sliding block, a connecting shaft, a threaded rod, a soft cushion, a fixed shell, a movable plate and a wiring groove. When a rotating force is applied to the rotary knob, the rotary knob can control the threaded rod to rotate and drive the sliding block to horizontally move front and back. The modularized integrated multifunctional network security protection device provided by the invention is provided with a fixing structure and a connecting structure; the fixing structure can firmly fix the network security protection hardware equipment in the shell, the shell can realize single placement of the security equipment, the situation that a plurality of security equipment are overlapped together during use is avoided, and the connecting structure can connect a plurality of shells together, so that the shells are connected more fixedly.

Owner:魏文爽

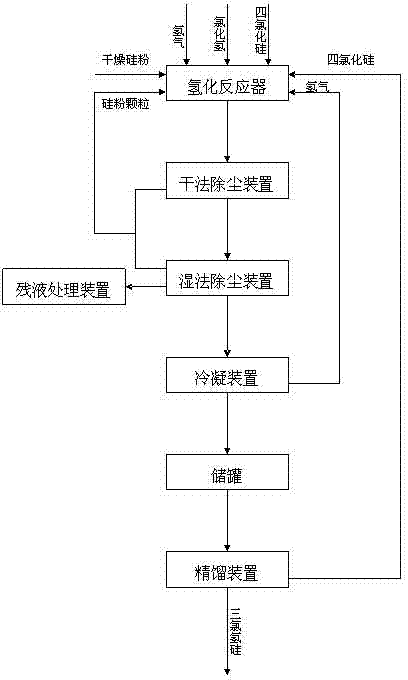

Method and device for improving hydrogenation of silicon tetrachloride

InactiveCN102897770ALower reaction costEasy to removeHalogenated silanesPhysical chemistryLiquid storage tank

The invention discloses a method and device for improving the hydrogenation of silicon tetrachloride. The method comprises the following steps: flatly spreading metallic silicon powder of which the purity is 95-98% in a hydrogenation reactor, continuously introducing preheated silicon tetrachloride gas, hydrogen gas and hydrogen chloride gas, and reacting to obtain mixed gas A; enabling the mixed gas A to be sequentially subjected to dry dust removal and wet dust removal to obtain mixed gas B; cooling the mixed gas B until mixed liquid C is obtained; and transferring the mixed liquid C to a rectification device, and separating. The device disclosed by the invention comprises the hydrogenation reactor, a dry dust removal device, a heat recovery device, a wet dust removal device, a cooling device, a liquid storage tank and the rectification device which are sequentially connected, wherein the liquid storage tank is also connected to the wet dust removal device. The method and the device for improving the hydrogenation of silicon tetrachloride, provided by the invention, have the advantages of simple and convenient operation process, high continuity and stability, energy saving and consumption reduction.

Owner:内蒙古锋威硅业有限公司

Smart classroom intelligent correction and data acquisition method based on ink screen

PendingCN114049805AReduce photo identificationImprove user experienceTransmissionElectrical appliancesEngineeringServer-side

The invention discloses a smart classroom intelligent correction and data acquisition method based on an ink screen, and the method comprises the steps: enabling a teacher end to issue homework or test paper data to a student end through a server end after a binding relation is established between the teacher end and the student end, enabling a student to write and answer on the ink screen of the student end; and enabling the student end to collect the answer content of the student and send the answer content to the teacher end through the server end for intelligent correction. According to the invention, based on the use of the ink screen, automatic acquisition of the answering content by the student terminal can be realized, complicated steps such as photographing identification required by a traditional acquisition mode are reduced, and the use experience of teachers and students is improved.

Owner:珠海读书郎软件科技有限公司

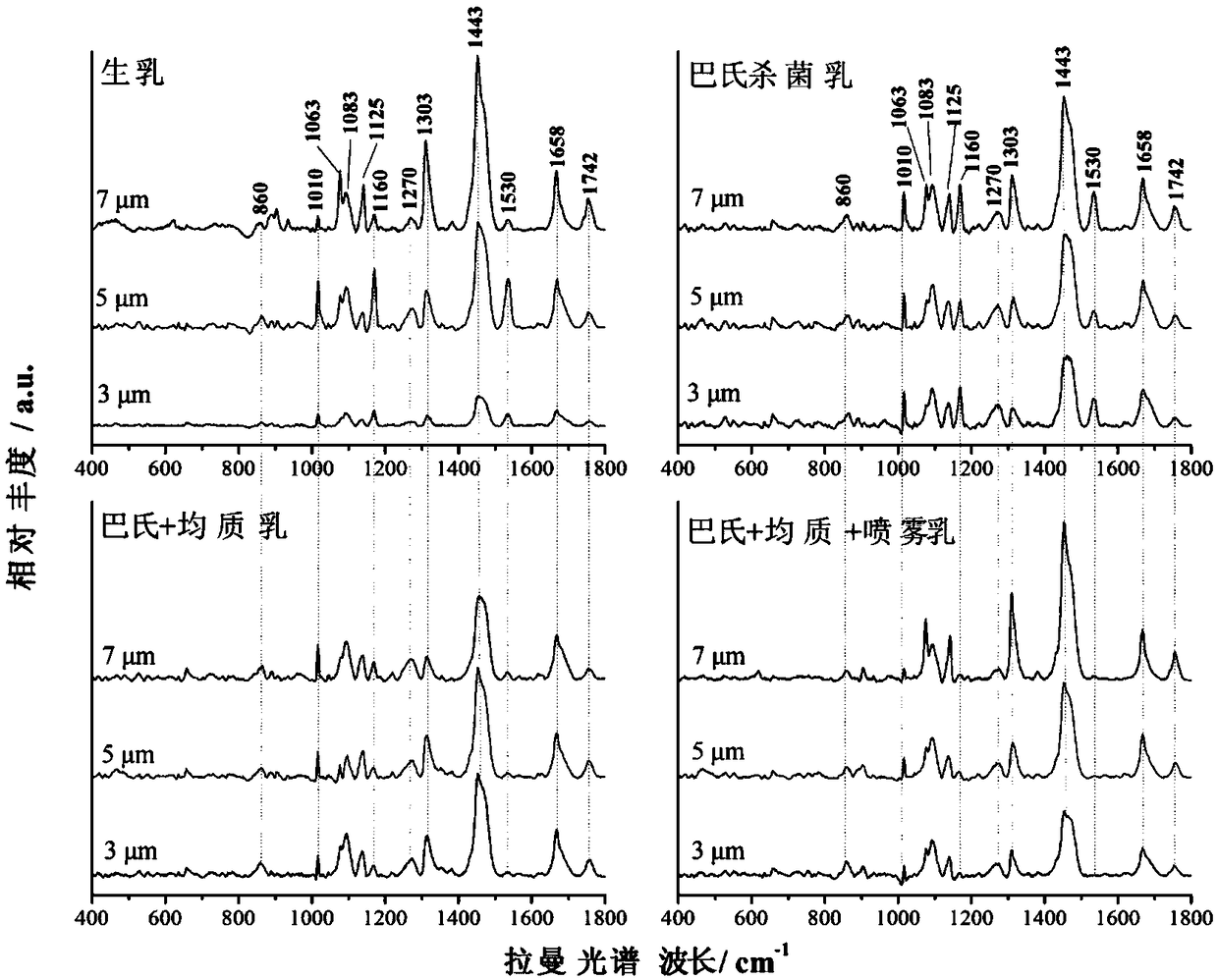

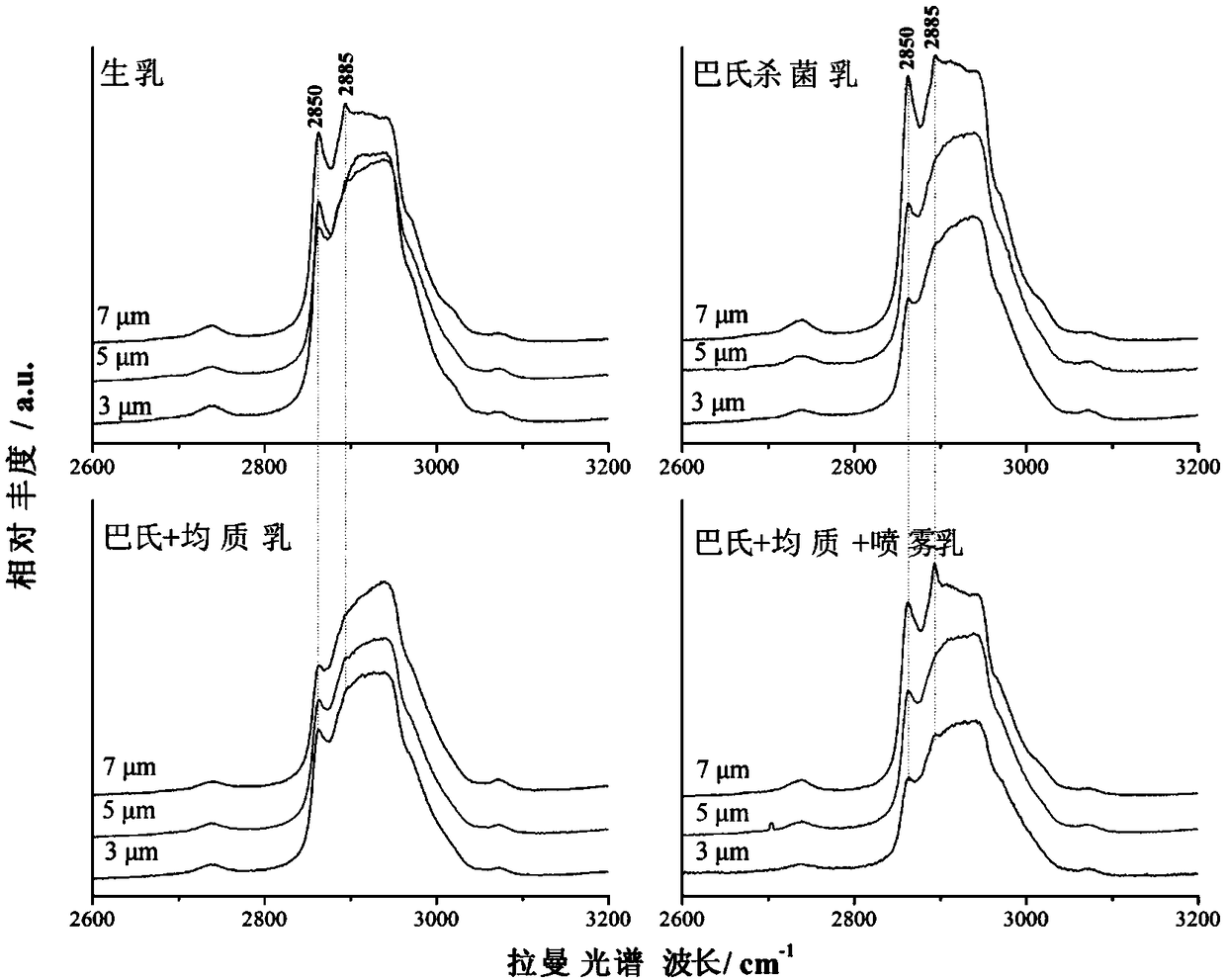

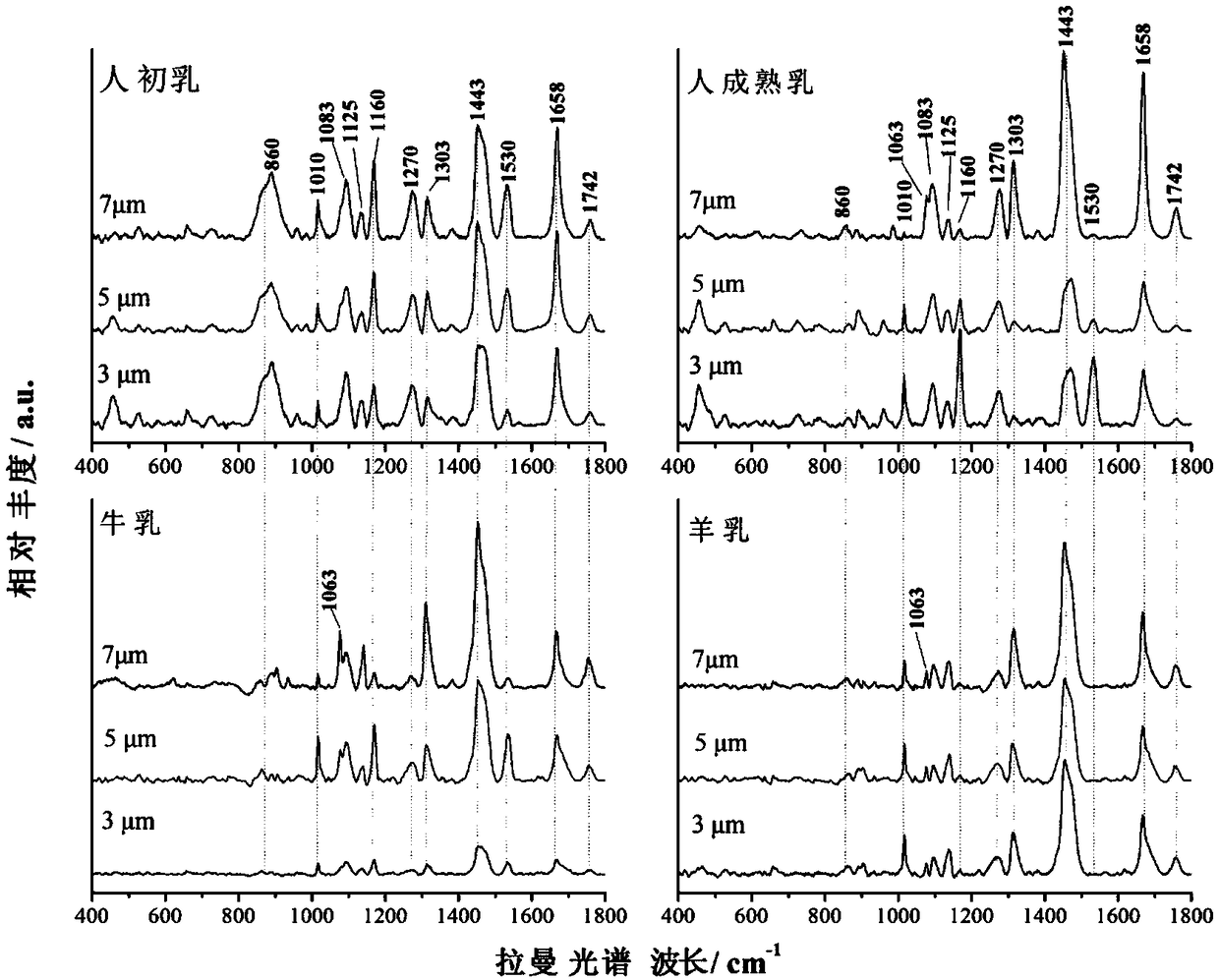

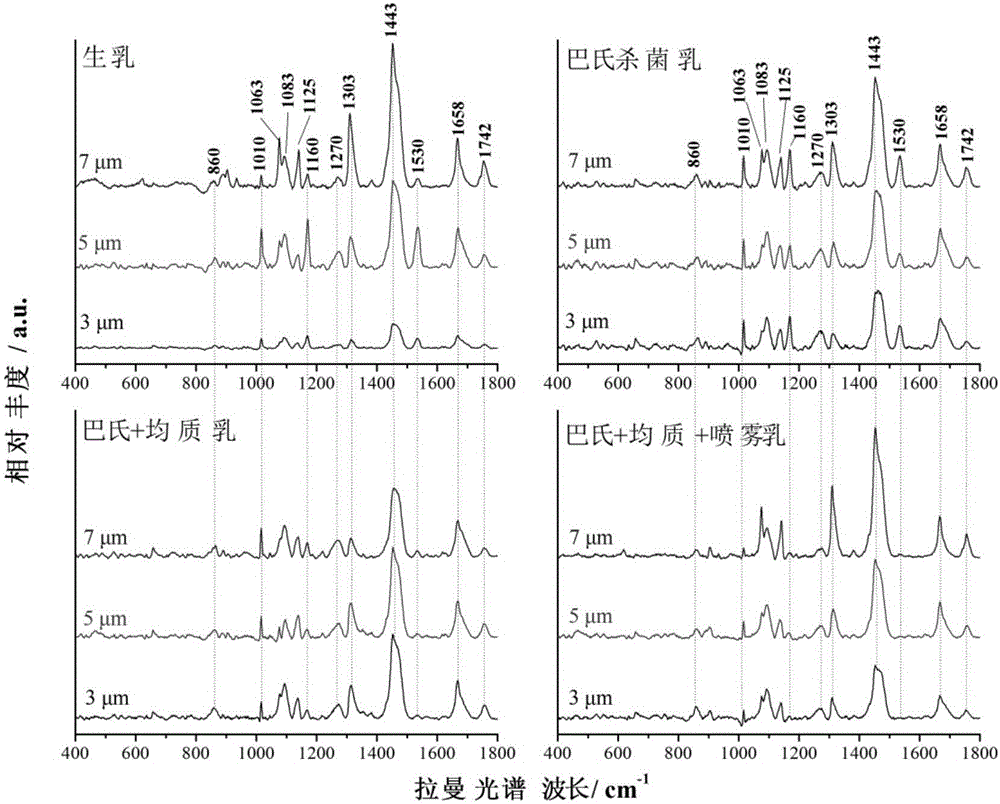

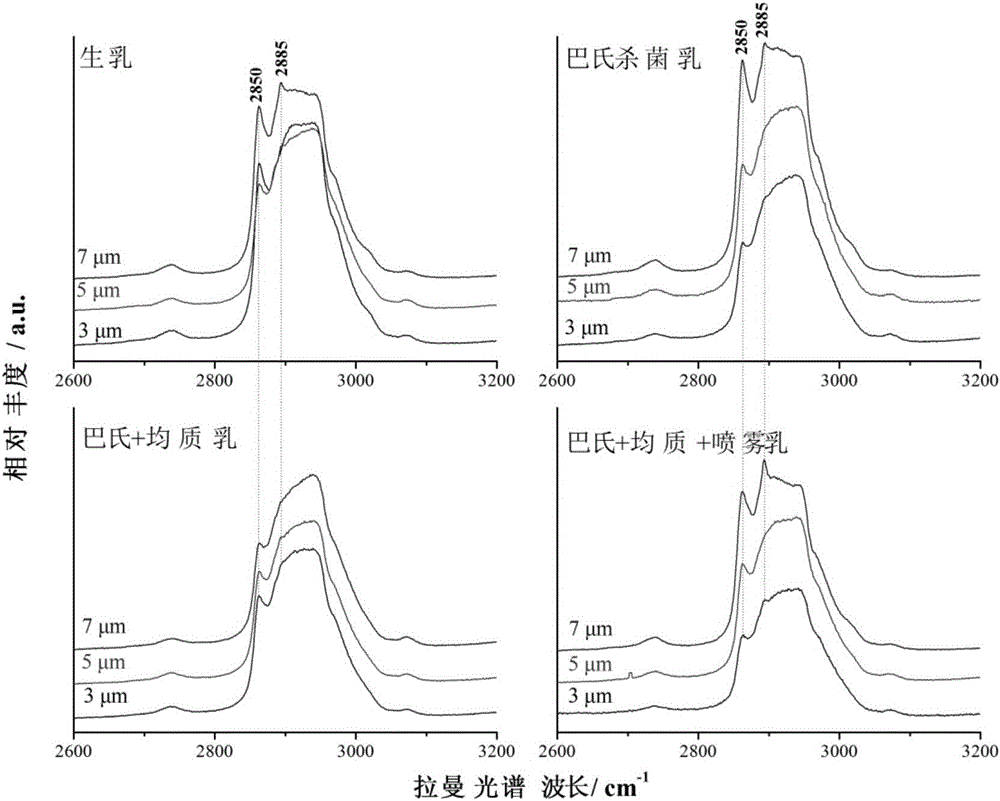

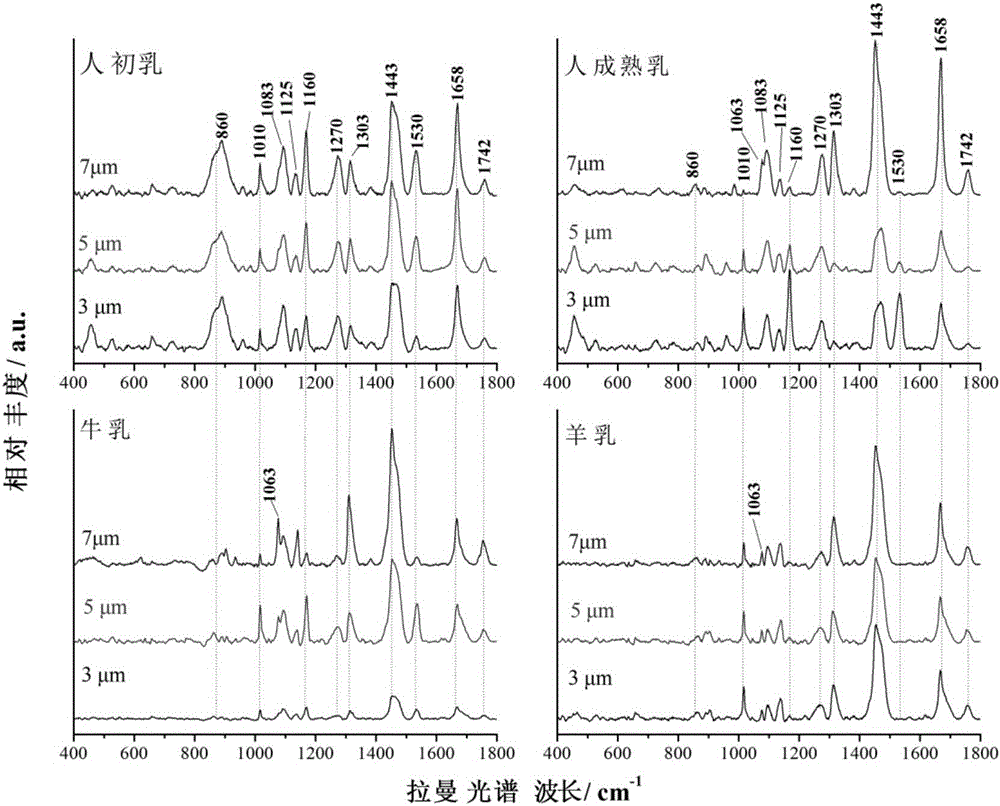

A rapid method for evaluating lipid composition in different milk fat globules

ActiveCN106290297BReduce complicated stepsShort detection timePreparing sample for investigationRaman scatteringMilk sampleLipid composition

The invention provides a method for rapidly evaluating lipid compositions in different milk fat globules. The method includes the steps of collecting Raman spectrum charts of the milk fat globules of different sizes in a to-be-tested milk sample through a Raman spectrum analysis system after the to-be-tested milk sample is mixed with agarose, comparing characteristic peaks of the Raman spectrum charts, and judging the contents of lipid compositions through the comparison of strength of the characteristic peaks. By means of the Raman spectrum analysis system, compared with a traditional method, the method has the advantages that all complicated steps for extracting lipid in milk are omitted, spent detection time is short, cost is reduced, efficiency is improved, and the contents of lipid compositions in the milk fat globules of different sizes can be compared.

Owner:JIANGNAN UNIV

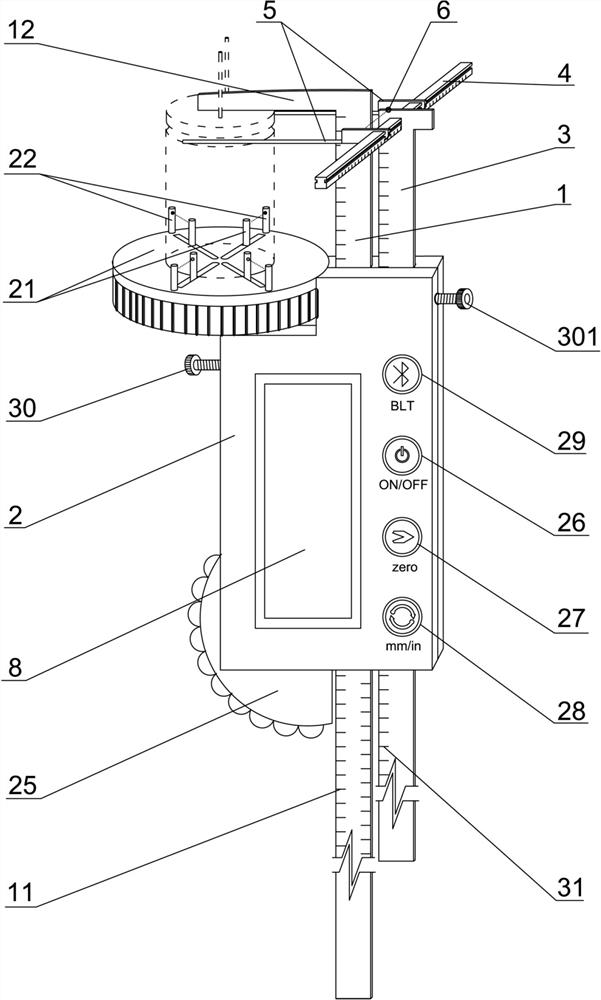

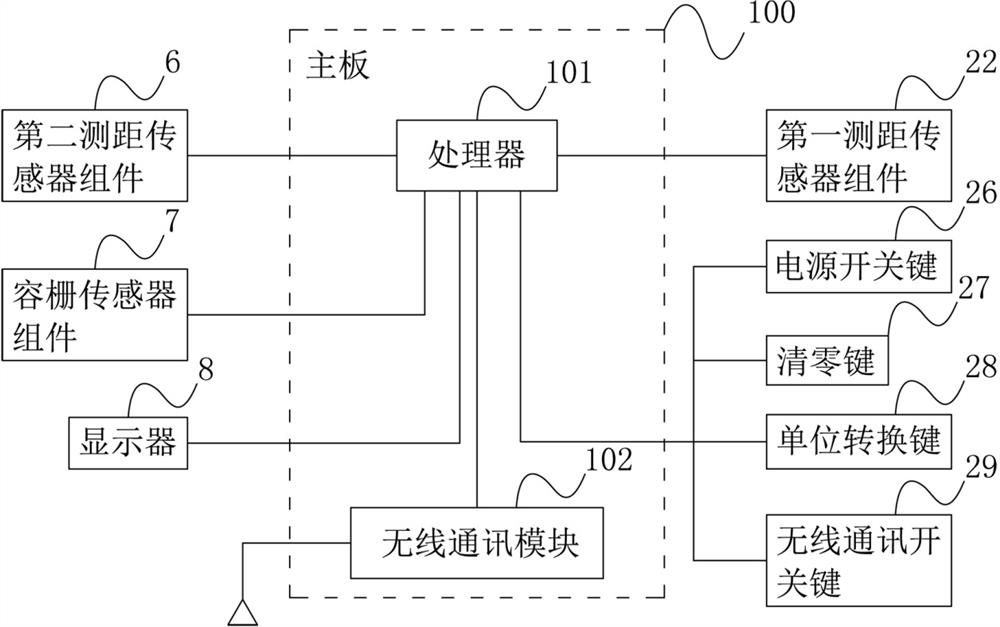

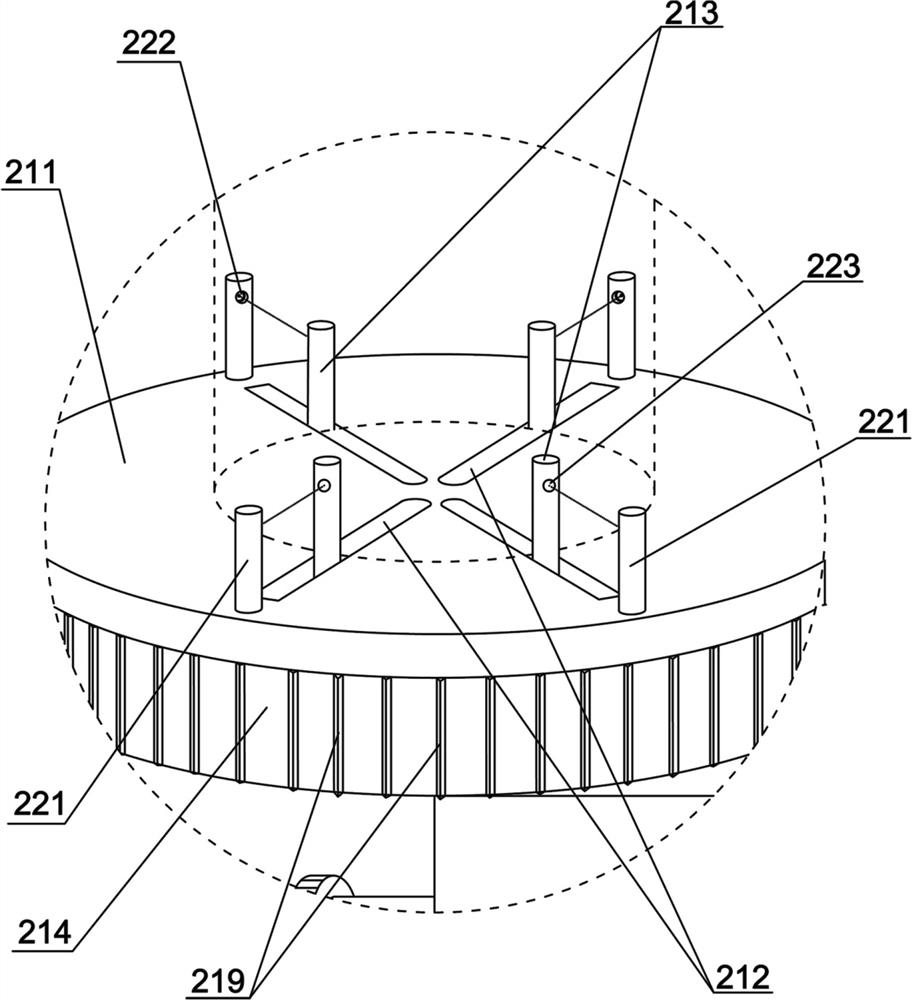

Digital caliper for rapidly measuring various sizes of capacitors

PendingCN113494873AReduce workloadReduce complicated stepsSlide gaugesUsing subsonic/sonic/ultrasonic vibration meansGratingDisplay device

The invention provides a digital caliper for rapidly measuring various sizes of capacitors, belonging to the technical field of measuring tools. The invention aims to solve the technical defect that existing digital display calipers are not suitable for batch detection of the sizes of the capacitors. According to a technical scheme in the invention, the digital caliper comprises a main caliper, a caliper frame, a circular bearing platform mechanism, a first distance measuring sensor assembly, an auxiliary caliper, a longitudinal measuring rod, girdling anvil assemblies, a second distance measuring sensor assembly, a capacitive grating sensor assembly, a processor and a display. The digital caliper has the beneficial effects that a measured capacitor is clamped through the circular bearing platform mechanism and a main caliper measuring jaw; the height of the measured capacitor and the height of a girdling part are measured through the main caliper and the auxiliary caliper; the diameter of the measured capacitor is measured through the first distance measuring sensor assembly located on the periphery of the measured capacitor; the girdling part is clamped through the girdling anvil assemblies correspondingly connected to the two ends of the longitudinal measuring rod in a sliding mode; the diameter of the girdling part is measured through the second distance measuring sensor assembly; values of various sizes of the measured capacitor are obtained through the processor and are displayed through the display; and the purpose of measuring various sizes of the capacitor at a time is achieved, and detection efficiency is high.

Owner:深圳市新中元电子有限公司

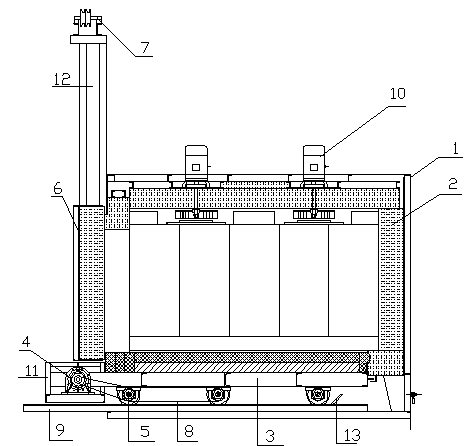

Portable trolley furnace

The invention discloses a portable trolley furnace which comprises a furnace body, a furnace door, a trolley and a plurality of wheels located below the trolley, wherein the furnace body comprises a furnace shell and a furnace lining, the trolley is located below the furnace body, and the lengths, exposed from the trolley, of the two sides of the furnace body are equal to the thickness of the furnace door. When the trolley is located at the leftmost end, a feeding platform is arranged below the furnace door, the wheels are located below the trolley and embedded in tracks, a draught fan is arranged above the furnace body, the front end of the draught fan is embedded in the furnace body, and seamless welding is adopted for a connecting surface. The portable trolley furnace has the advantages that heat loss is avoided during heating, products heated in the furnace do not need to be removed during cooling, cooling can be achieved only by starting the draught fan and opening the furnace door to enable cross-ventilation between the inside of the furnace and the outside of the furnace to be achieved, and certain complicated processes are omitted.

Owner:JIANGSU GAOHAO IND FURNACE

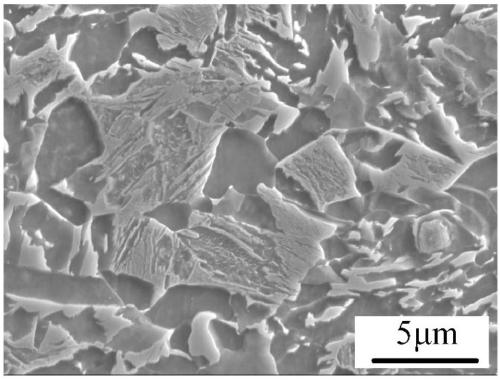

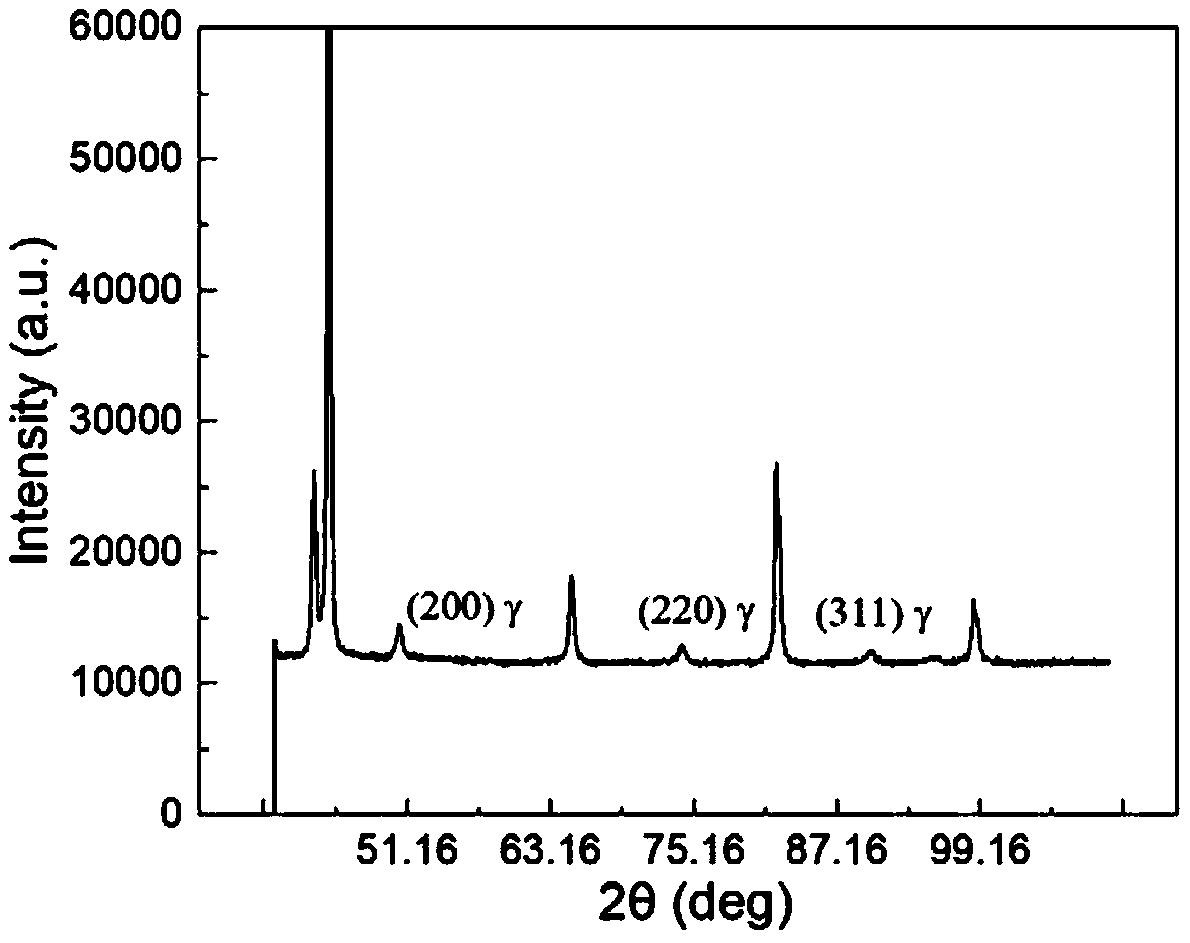

A kind of low-density fe-mn-al-c hot-rolled q&p steel and its manufacturing method

The invention belongs to the technical field of steel alloy materials, and specifically relates to a low-density Fe-Mn-Al-C hot-rolled Q&P steel and its manufacturing method. The chemical composition of low-density hot-rolled Q&P steel is: 0.22 to 0.25% C, 2.8 to 3.2% Mn, 1.8 to 2.2% Al, and the balance is Fe. After controlled rolling, the experimental steel was air-cooled online to 280-340°C, and then furnace-cooled to room temperature. Finally, a complex Q&P structure with a small amount of ferrite, martensite and retained austenite was obtained, with a tensile strength of ≥1135MPa and an elongation of >19%. Compared with existing Q&P steel, the present invention reduces the density of experimental steel through reasonable composition design, and weakens the dependence of martensite transformation on cooling rate. It replaces the quenching process with air cooling and overcomes the problems caused by online low-temperature quenching (below Ms). Problems such as uneven structural properties and poor plate shape.

Owner:NORTHEASTERN UNIV LIAONING

Hot-rolled fe-mn-al-c steel obtained by quenching to bainite zone to obtain q&p structure and manufacturing method

The invention belongs to the technical field of steel alloy materials, and specifically relates to a hot-rolled Fe-Mn-Al-C steel that is quenched to the bainite zone to obtain a Q&P structure and a manufacturing method. The chemical composition of hot-rolled Fe‑Mn‑Al‑C steel is: 0.22% to 0.25% C, 2.8% to 3.2% Mn, 1.8% to 2.2% Al, and the balance is Fe. By controlling the phase transformation kinetics through composition design, the experimental steel is cooled to above the Ms temperature, and then is slowly cooled to avoid sufficient bainitic phase transformation and obtain a martensite / bainite-based structure. After controlled rolling, the experimental steel was air-cooled online to 500-550°C, and then furnace cooled to room temperature. Finally, a complex Q&P structure with a small amount of ferrite, martensite / bainite, and retained austenite was obtained. The tensile strength was > 1050MPa, elongation >20%. Thus, the problem of low-temperature quenching of hot-rolled Q&P steel being difficult to control is solved.

Owner:NORTHEASTERN UNIV LIAONING

Catalyst-absorbent complex for absorbing and strengthening low-carbon hydrocarbon steam reforming hydrogen and preparing method of complex

InactiveCN102949997BImprove catalytic performancePromote absorptionProductsHydrogenSteam reformingPtru catalyst

The invention discloses a catalyst-absorbent complex for absorbing and strengthening low-carbon hydrocarbon steam reforming hydrogen and a preparing method of the complex, which are mainly used for the steam reforming hydrogen production through low-carbon hydrocarbons of C1-C4 and the like. The method is characterized in that a coprecipitation method is adopted to organically combine a catalyst for hydrocarbon steam reforming reaction and an absorbent for CO2 carboxylation reaction to form a whole body, so that micro-scale uniform distribution is realized, thus a precursor with a hydrotalcite structure is formed, and the catalyst-absorbent complex is prepared through high temperature sintering. The complex can effectively stimulate CO2 situ absorption, and excellent catalyzing and absorbing activities and stability of the complex are maintained through the hydrotalcite structure of the precursor. The chemical formula of the complex is Nix-Mgy-Caz-Al-O.

Owner:EAST CHINA UNIV OF SCI & TECH

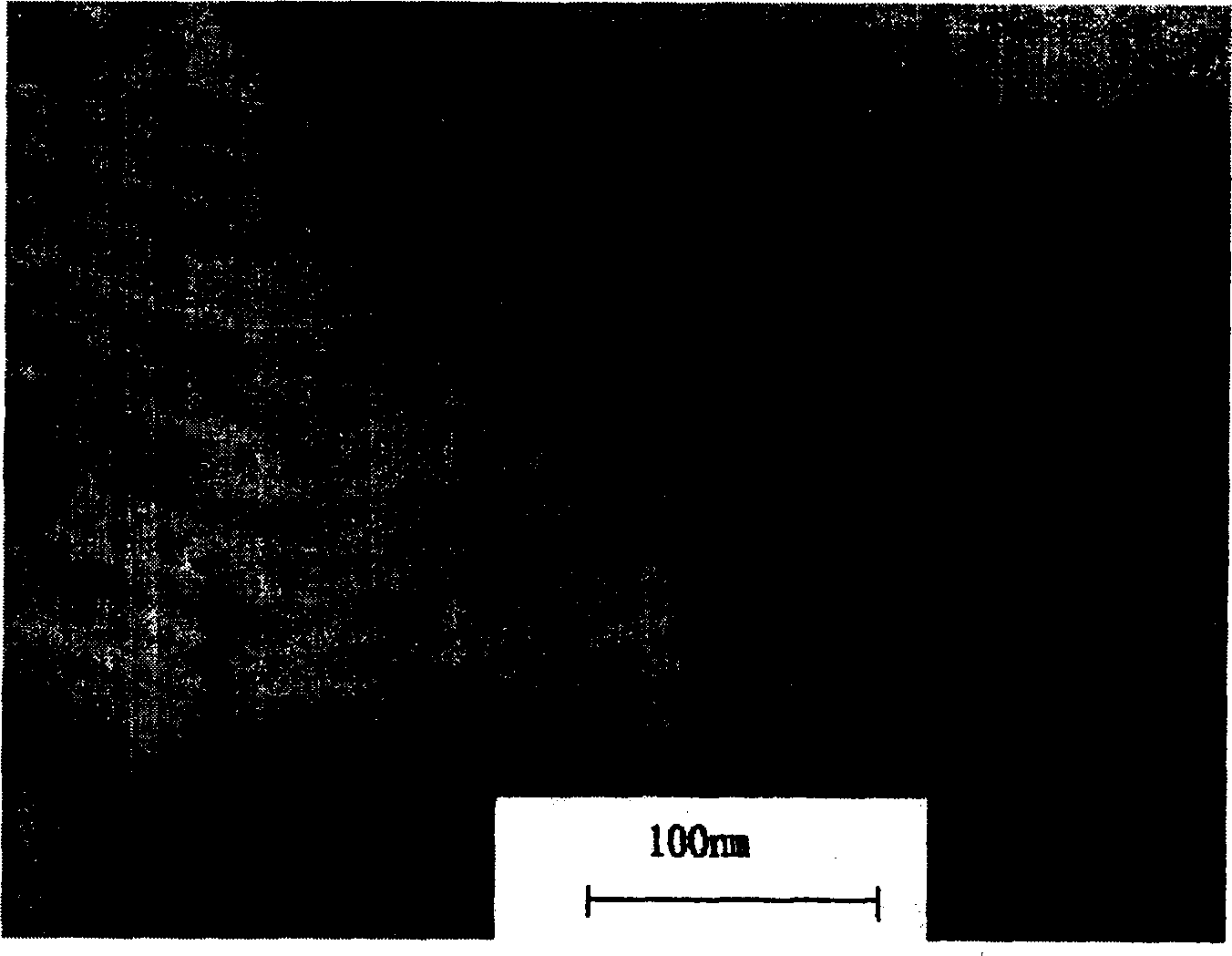

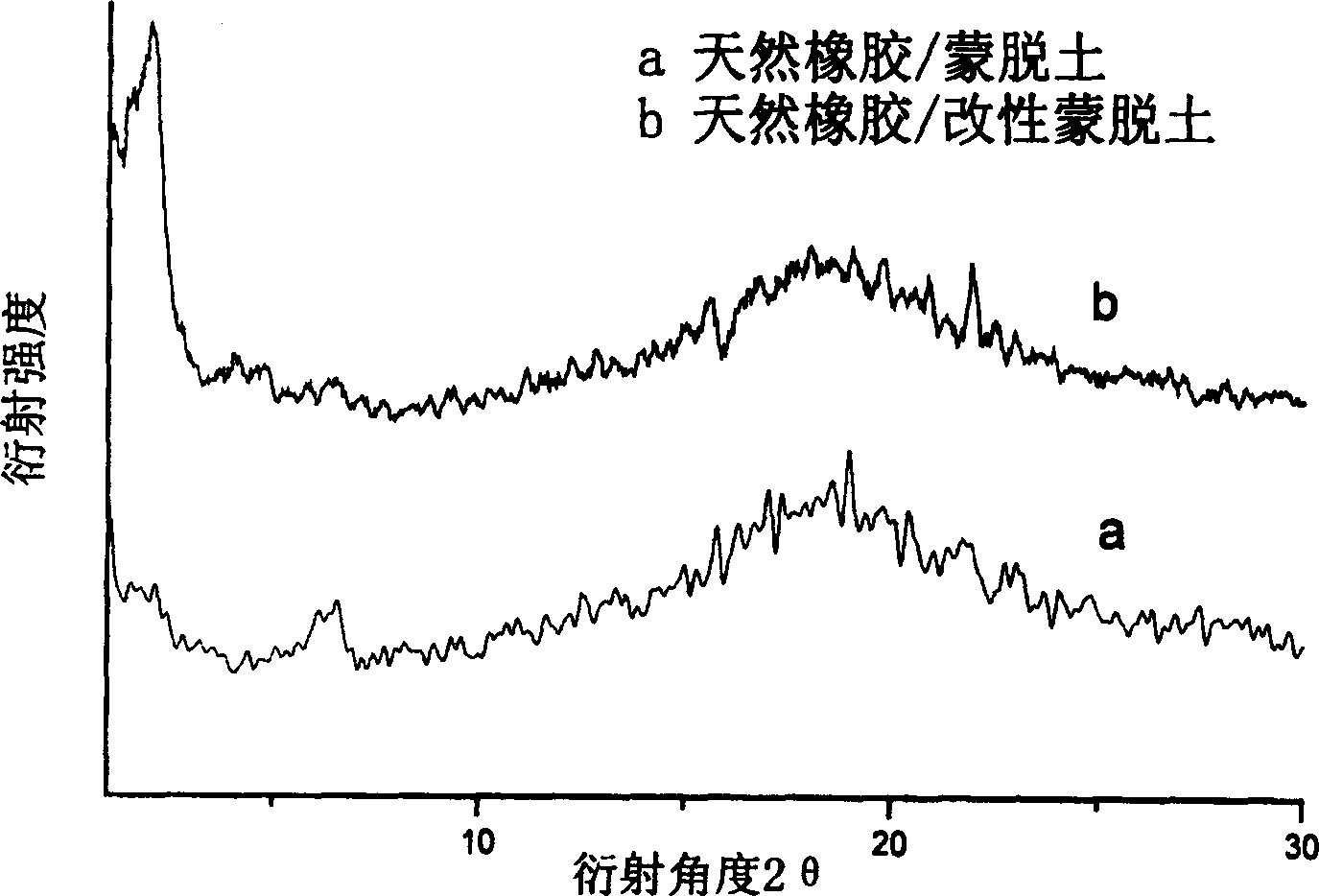

Method for preparing modified montmorillonite for polymer/inorganic nano composite material

The invention relates to a simple and feasible preparation method of modified montmorillonite for polymer / inorganic nanocomposite materials. After reaction modification, the obtained modified montmorillonite can be directly used in polymer / montmorillonite nanocomposite materials to realize effective intercalation of polymer macromolecules between montmorillonite layers and obtain nanocomposite materials with excellent performance. The method has the advantages of simplicity, low production cost, no need to use water or solvent, no environmental pollution, etc., and has good industrial application prospects.

Owner:SOUTH CHINA UNIV OF TECH

Quick test method

InactiveCN103134760AImprove detection limitReduce complicated stepsPreparing sample for investigationColor/spectral properties measurementsPhosphateOil quality

The invention relates to a quick test method. Firstly, rice bran is partially degreased, lipoxidase in the rice bran which is partially degreased is extracted with a buffer solution, the lipoxidase extracting solution is added to a prepared phosphate-linoleic acid-polysorbate 20 substrate solution, changes of light-absorption photometric values are tested under 234 nm in 5 minutes, meanwhile, the protein content in the lipoxidase extracting solution is tested, and then activity of the lipoxidase in the rice bran can be obtained. According to the method, the activity of the lipoxidase in the rice bran is effectively activated through partial degreasing, the detection limit is raised, the buffer solution, the substrate solution and passivating crude enzyme serve as reference solutions, test errors of the crude enzyme are effectively eliminated, and complicated steps of passivating of the crude enzyme are eliminated. The method is easy and convenient to operate, precise in result, good in reproducibility, capable of being widely used for grain and oil quality test and control in grain processing enterprises, storage enterprises and grain and oil test organizations.

Owner:JIANGSU HUAFENG TOOLS

Method for rapidly evaluating lipid compositions in different milk fat globules

ActiveCN106290297AReduce complicated stepsShort detection timePreparing sample for investigationRaman scatteringLipid formationMilk sample

The invention provides a method for rapidly evaluating lipid compositions in different milk fat globules. The method includes the steps of collecting Raman spectrum charts of the milk fat globules of different sizes in a to-be-tested milk sample through a Raman spectrum analysis system after the to-be-tested milk sample is mixed with agarose, comparing characteristic peaks of the Raman spectrum charts, and judging the contents of lipid compositions through the comparison of strength of the characteristic peaks. By means of the Raman spectrum analysis system, compared with a traditional method, the method has the advantages that all complicated steps for extracting lipid in milk are omitted, spent detection time is short, cost is reduced, efficiency is improved, and the contents of lipid compositions in the milk fat globules of different sizes can be compared.

Owner:JIANGNAN UNIV

CPP film book cover production process

PendingCN114714639AReduce complicated stepsImprove work efficiencyFlat articlesMetal working apparatusThin membraneProcess engineering

The invention discloses a CPP thin film book cover production process, relates to a thin film production and processing technology, and aims to solve the problems that the production efficiency is easily influenced during production due to more and more complicated steps of an original book cover manufacturing method, and meanwhile, the edge of a CPP thin film obtained by cutting is sharp, so that people are easily scratched. According to the technical scheme, the method is characterized by comprising the following steps that firstly, materials are weighed and mixed; step 2, feeding and stirring: sequentially feeding the materials into a hopper stirrer, feeding a small amount of materials at a middle section, and continuously stirring for a certain time after all the materials are fed; 3, pumping and melting the materials, and pumping the stirred materials into a CPP casting machine for heating; and 4, film blowing, wherein after the temperature in the CPP casting machine reaches the set temperature, material injection and film blowing are started. Production can be carried out through thermal shaping, the production steps can be reduced, the working efficiency is improved, the edge of the obtained book cover is round, and people are not prone to being hurt when touching the book cover.

Owner:浙江本源纸塑科技有限公司

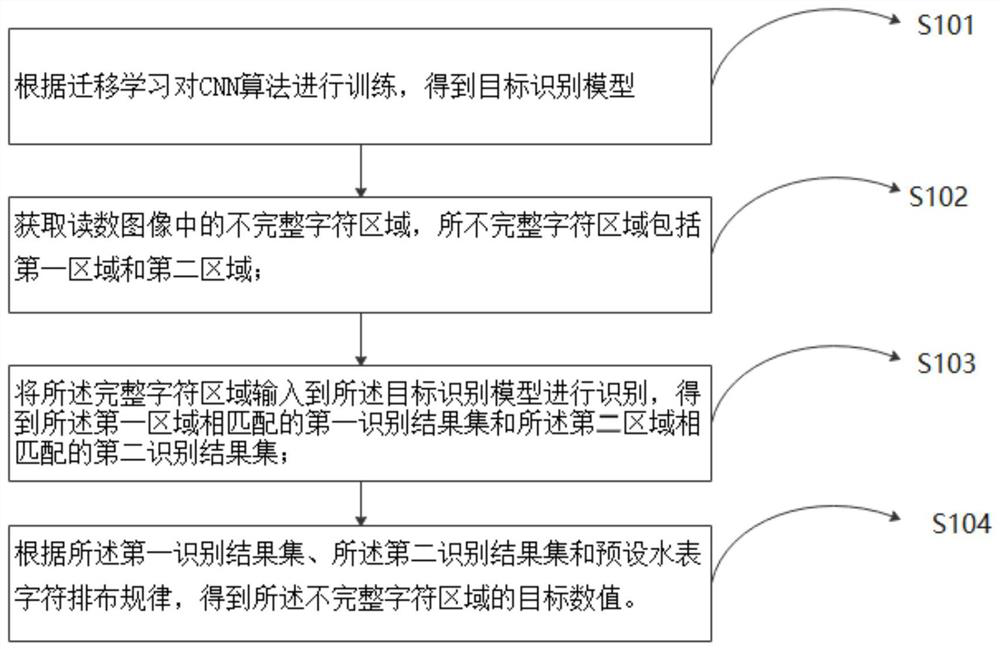

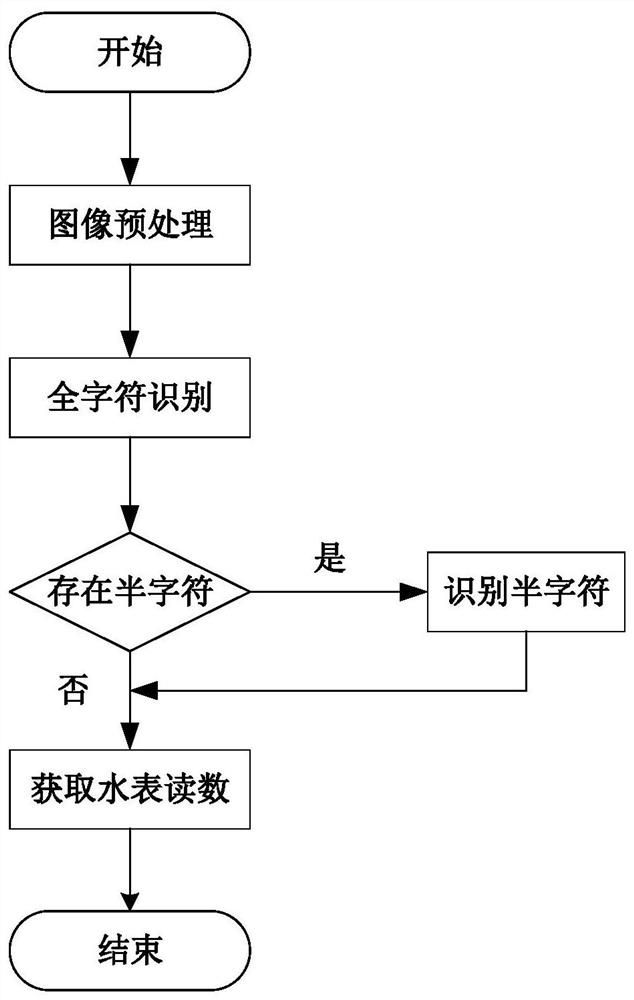

Reading meter incomplete character recognition method and reading meter character recognition method

PendingCN113269194AEasy to identifyImprove accuracyNeural learning methodsCharacter recognitionGoal recognitionResult set

The invention provides a reading meter incomplete character recognition method, and the method comprises the steps: training a CNN algorithm according to transfer learning, and obtaining a target recognition model; obtaining an incomplete character region in the reading image, wherein the incomplete character region comprises a first region and a second region; inputting the complete character region into the target recognition model for recognition to obtain a first recognition result set matched with the first region and a second recognition result set matched with the second region; and obtaining a target value of the incomplete character region according to the first recognition result set, the second recognition result set and a preset reading table character arrangement rule. According to the method, through transfer learning of the training model and further screening and judgment of the first recognition result set and the second recognition result set, the technical problems of incomplete character recognition and inaccurate character recognition of a traditional reading meter are solved.

Owner:SICHUAN CHANGHONG NETWORK TECH CO LTD

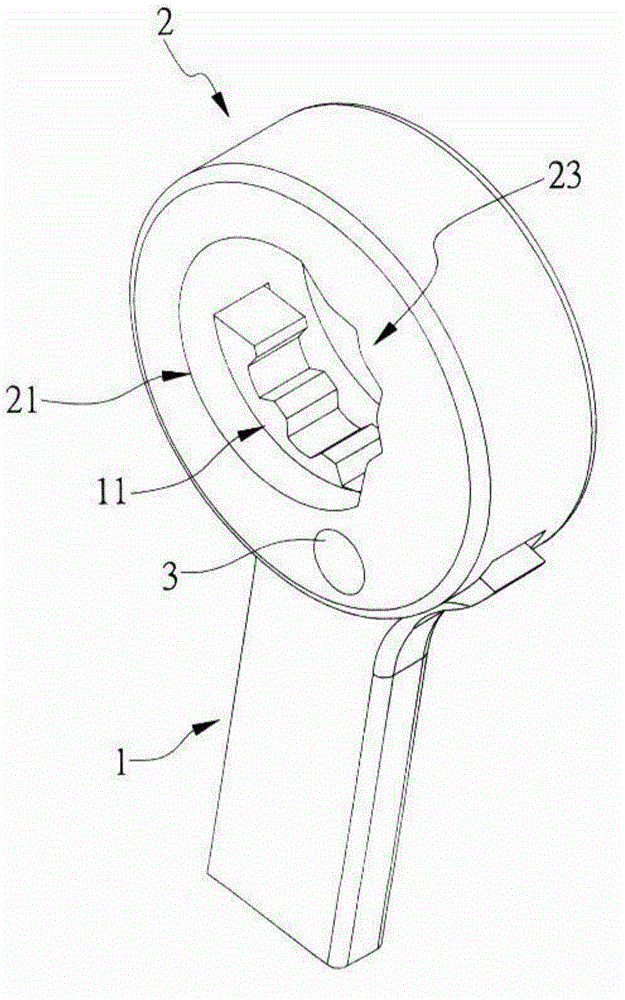

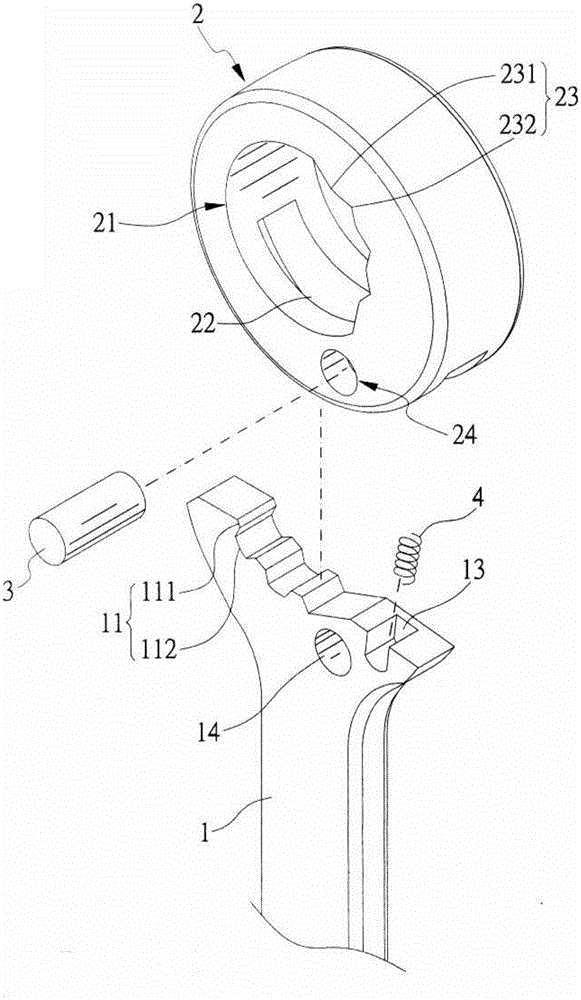

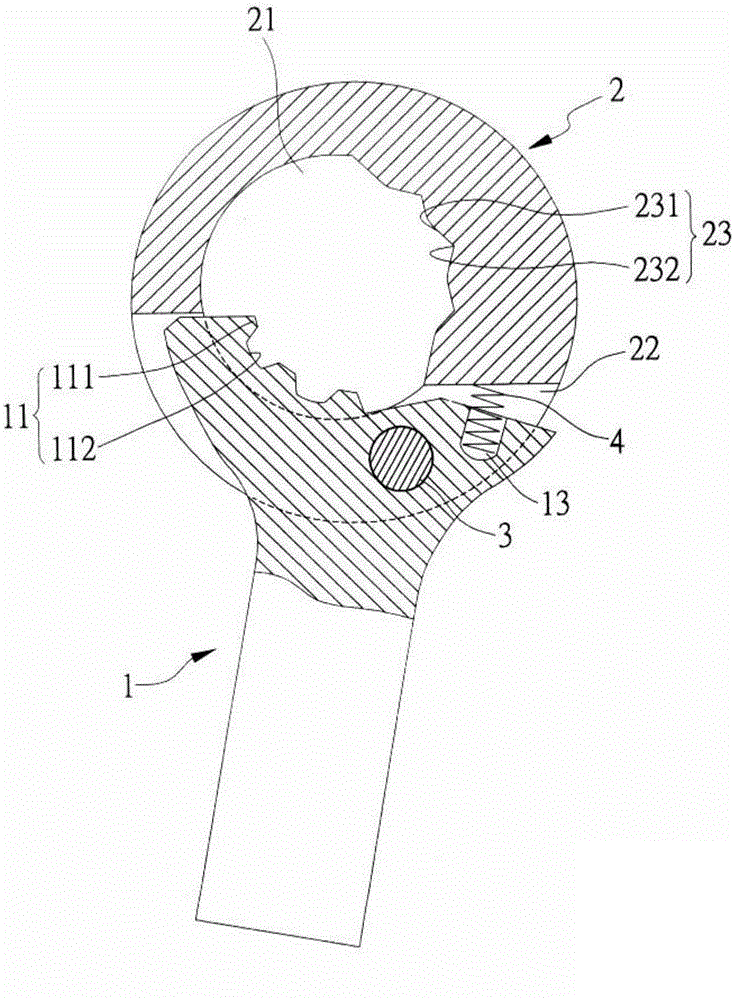

Pressing type spanner repeatedly operated

The invention discloses a pressing type spanner repeatedly operated. According to the spanner, one end face of a drive handle part is provided with an abutting part and an accommodating groove, the other end of the drive handle part is provided with a holding part, and a pivot hole is formed between the abutting part and the accommodating groove in a penetration mode; a ring sleeve part is provided with a nesting hole in a penetration mode, a sectioning hole is formed in the peripheral side of the ring sleeve part and communicates with the nesting hole, the end, provided with the abutting part, of the drive handle part is inserted into the sectioning hole, the ring sleeve part is provided with a punched hole corresponding to the pivot hole, and a bolt part penetrates through the punched hole and the pivot hole; an elastic part is arranged inside the accommodating groove; and a screw and a nut are arranged in the nesting hole in a penetration mode and are clamped and abutted by the abutting part and a wall of the nesting hole, the abutting part and the wall of the nesting hole can abut against the screw and the nut in a clamping mode for realizing locking and meshing through back-and-forth repeated pivoted swinging of the drive handle part, and slippage of the ring sleeve part can be elastically driven by the elastic part so that the meshing state can be removed.

Owner:SON YUIOS IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com