Method for rapidly evaluating lipid compositions in different milk fat globules

A milk fat globule and lipid technology, applied in the field of rapid evaluation of lipid composition in different milk fat globules, can solve the problems of inability to compare lipid composition of milk fat globules of different sizes, sample loss, etc., achieve short detection time and improve efficiency , cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

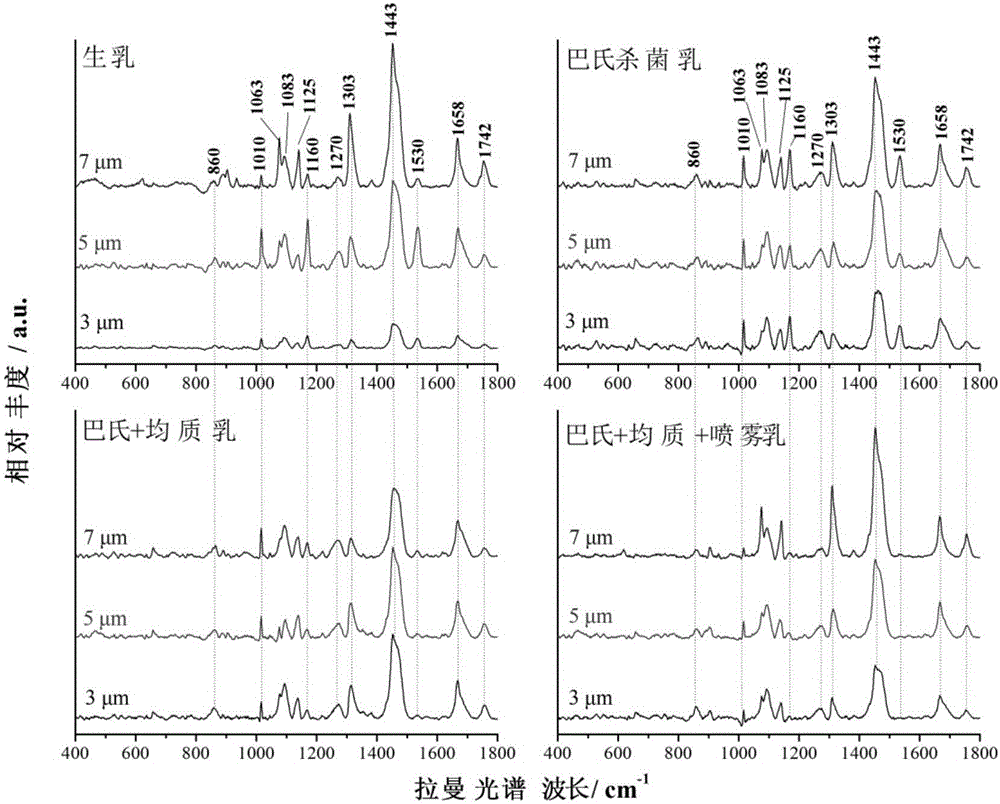

[0027] Centrifuge 3000g of raw milk to be tested, pasteurized milk, pasteurized and homogenized milk, pasteurized and homogenized and spray-dried rehydrated milk at 2000rpm for 5min, and collect the top fat layer in the Disperse in the simulated milk ultrafiltrate to make its fat content 20%, then dilute ten times and place it on a concave glass slide, add 50 μL (w / v) of agarose with a low melting point mass concentration of 0.5% to fix the sample, Quickly and gently cover with a coverslip. Adjust the working parameters of the Raman spectroscopic analysis instrument: grating 600gr / mm, acquisition time: 10s, accumulation times: 1, use 50×LWD, lens acquisition wavelength range 400~3200cm -1 , each sample was scanned three times and the average value was taken as its Raman spectrum. For sample injection, the sample must be kept in a static state, and the lipid composition in different milk fat globules can be qualitatively analyzed through the characteristic Raman frequency. In...

Embodiment 2

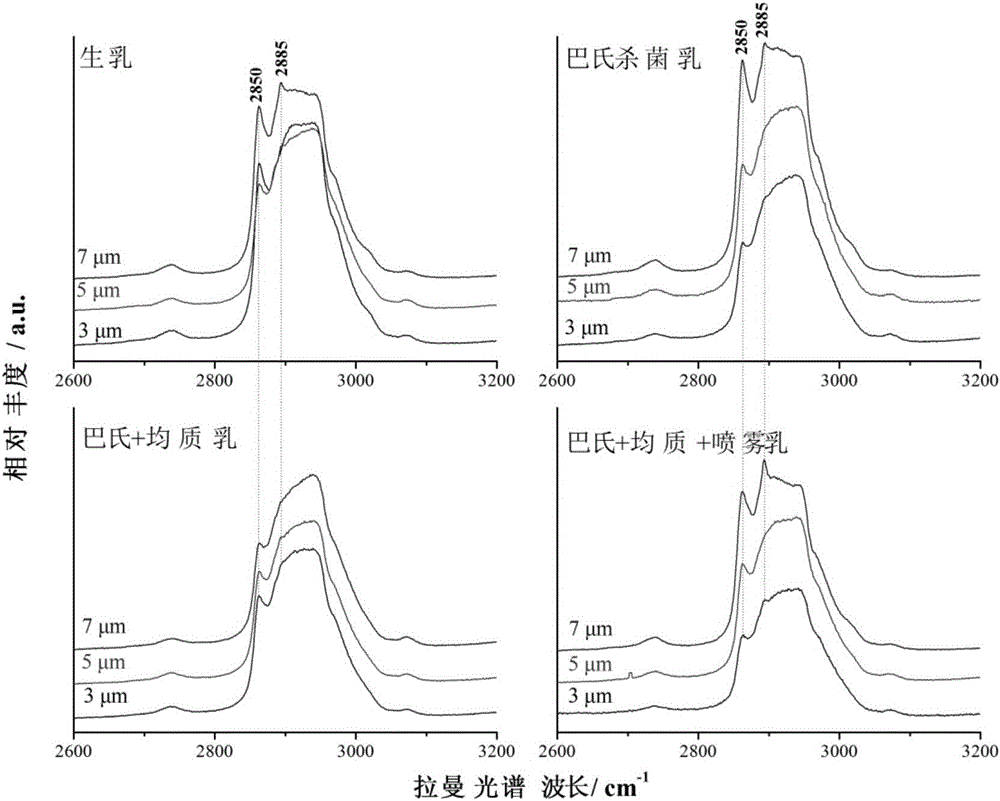

[0029] Centrifuge 3000g of raw milk to be tested, pasteurized milk, pasteurized and homogenized milk, pasteurized, homogenized and spray-dried rehydrated milk at 2500rpm for 8min, and collect the top fat layer in the Disperse in the simulated milk ultrafiltrate to make its fat content 15%, then dilute ten times and place it on a concave glass slide, add 40 μL (w / v) of low melting point agarose to fix the sample, and cover it quickly and gently On a cover glass, the working parameters of the Raman spectroscopic analysis system are: grating 600gr / mm, acquisition time: 10s, accumulation times: 1, use 50×LWD, lens acquisition wavelength range 2600~3200cm -1 . Injection results see figure 2 , where the substances represented by different wavelengths are indicated. 2850: Cholesterol. Then by the ratio z=peak height I of the characteristic peak intensity of each component1 / peak height I 2 , to compare its content, the characteristic peak intensity is the average intensity of 3...

Embodiment 3

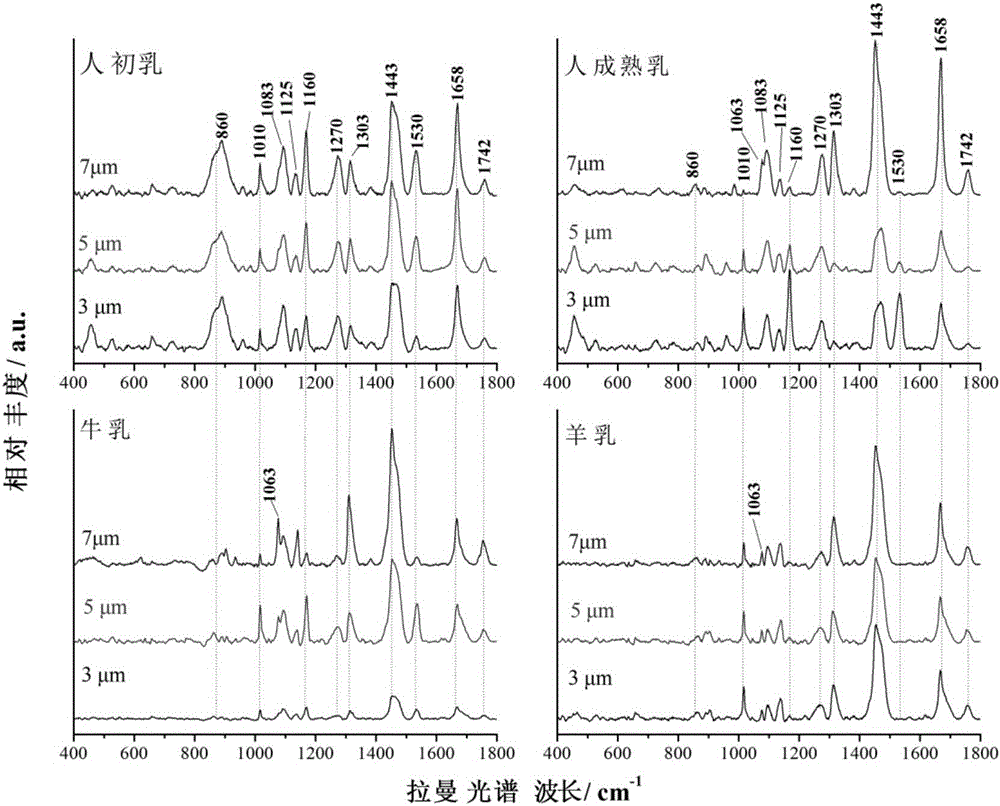

[0031] Centrifuge 3000g human colostrum, human mature milk, cow milk and goat milk fat globules respectively at 2500rpm for 10min, collect the top fat layer and disperse it in the simulated milk ultrafiltrate to make the fat content 20%, and then dilute ten times Add 45 μL (w / v) of low-melting point agarose to the concave slide to fix the sample, then quickly and gently cover it with a cover glass, and adjust the working parameters of the Raman spectroscopic analysis instrument: grating 600gr / mm, Acquisition time: 10s, accumulation times: 1, use 50×LWD, lens acquisition wavelength range 400~1800cm -1 . Injection results see image 3 , where the substances represented by different wavelengths are indicated. 860: phospholipids; 1010: fat-soluble carotenoids; 1160: fat-soluble carotenoids; 1270: C-H bonds in phospholipids; 1303: unsaturated bonds in phospholipids and cholesterol; 1443: saturated fatty acids; 1530: fat-soluble carotenoids 1658: unsaturated fatty acids; 1742: tr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com