CPP film book cover production process

A production process and film technology, which is applied in the field of CPP film book cover production process, can solve the problems of production efficiency impact, people scratching, and many steps, and achieve the effect of improving work efficiency, reducing complicated steps, and reducing steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

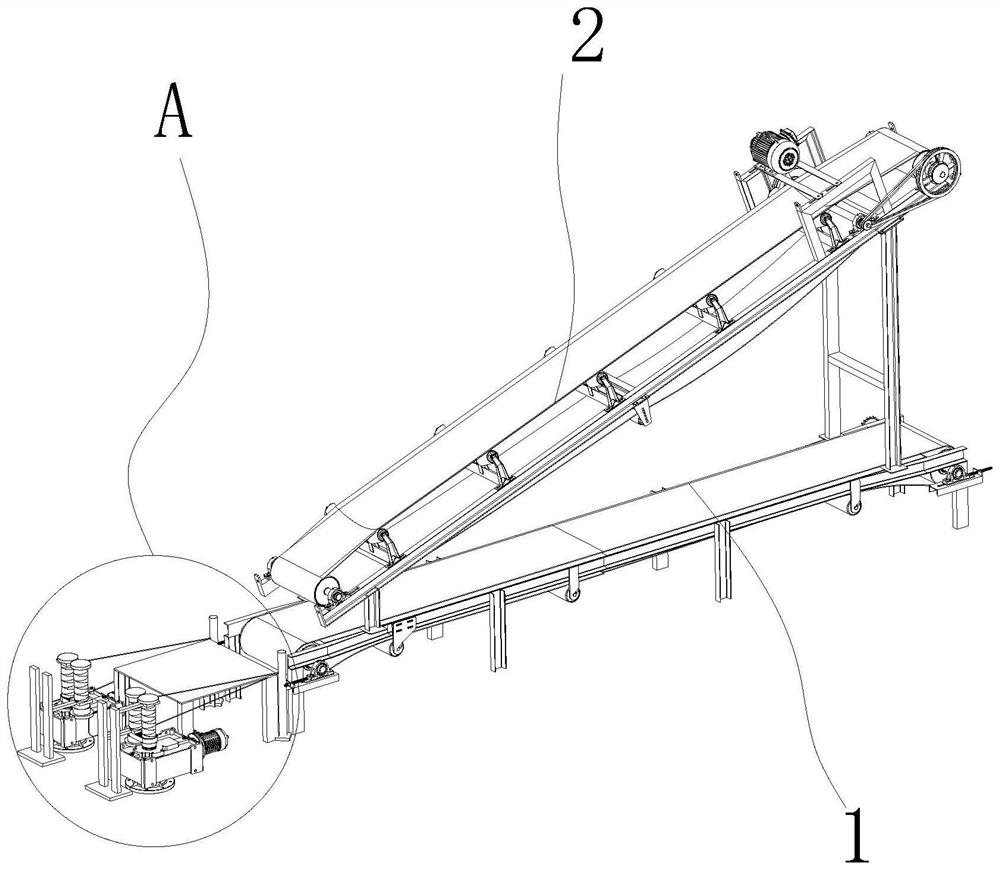

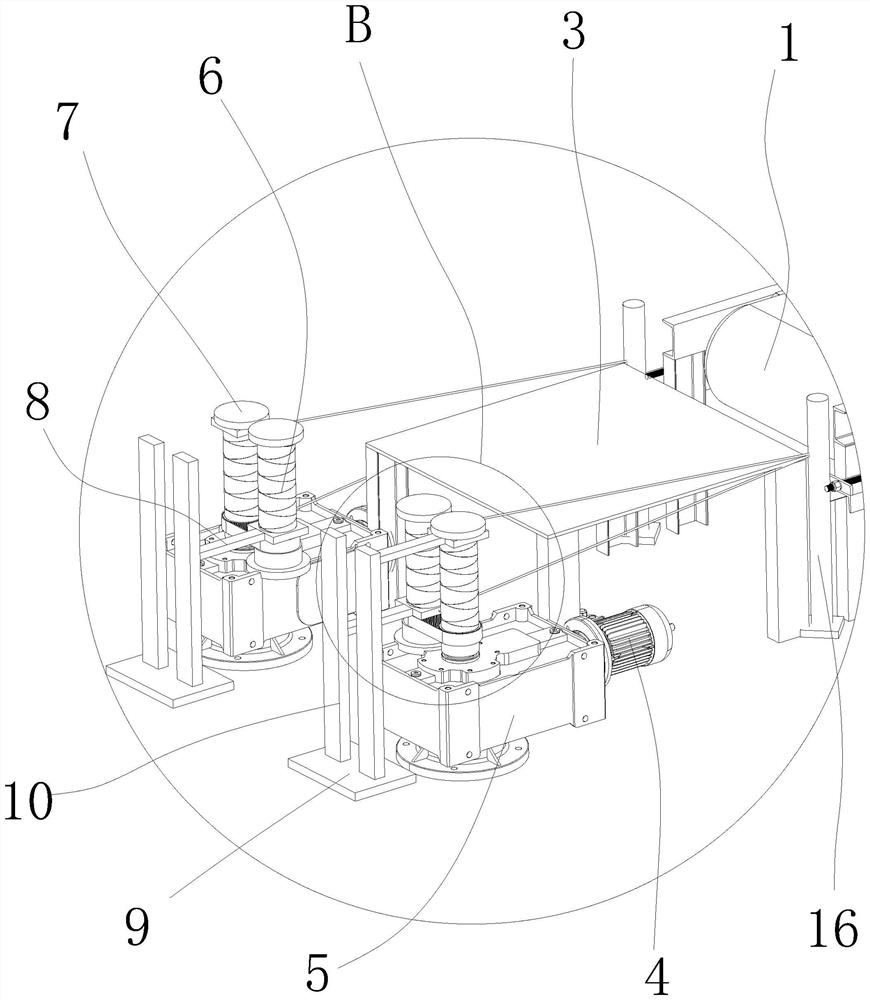

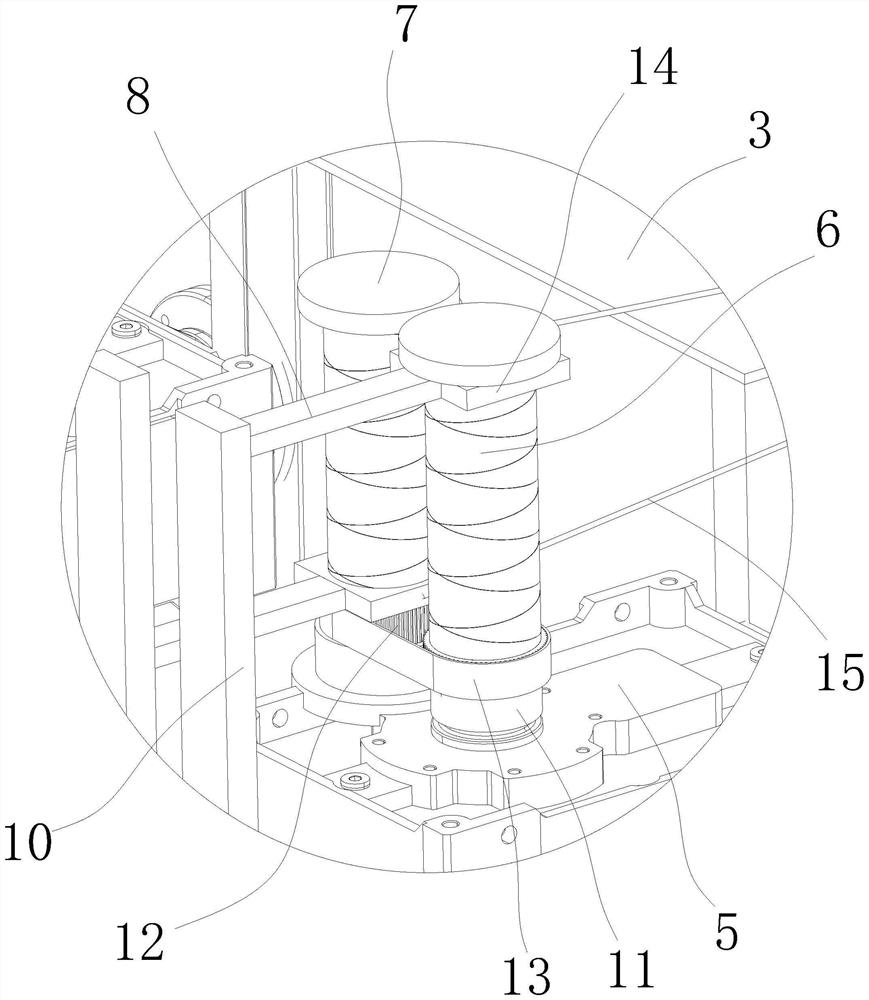

Image

Examples

Embodiment

[0032] The CPP film book cover production process includes the following steps:

[0033] Step 1, batching, weighing and batching the material;

[0034] Step 2, feeding and stirring, put the materials into the hopper mixer in turn, put the materials with a small amount in the middle section, the speed is 30 rpm, put the prepared materials into the feeding port in turn, and put the materials with a small amount in the middle, Make sure that the dispersion is uniform, and continue to stir for a certain period of time after all are put in. Continue to stir for 15 minutes. During the stirring process, foreign matter falls into the mixer. It is necessary to stop stirring for processing. Always pay attention to the supply of materials, and there should be no shortage of materials.

[0035] Step 3, the material is extracted and melted, the stirred material is pumped into the CPP casting machine for heating, the heating controller of the CPP casting machine is set, and the heating is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com