Hot-rolled fe-mn-al-c steel obtained by quenching to bainite zone to obtain q&p structure and manufacturing method

A fe-mn-al-c and manufacturing method technology, applied in the field of hot-rolled Fe-Mn-Al-C steel and manufacturing, can solve the problems of poor plate shape, uneven structure and properties, difficult low-temperature quenching control, etc. Effect of good control, improved surface quality, avoidance of differences in tissue properties and shape problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] In this example, the composition of the hot-rolled Fe-Mn-Al-C steel quenched to the bainite zone to obtain the Q&P structure is: C: 0.25%, Mn: 2.9%, Al: 1.9%, and the rest is Fe.

[0036] After smelting and forging, the billet is heated to 1200°C and kept for 1.5 hours. The first-stage rolling is carried out at 1180°C, and then the second-stage rolling is carried out by air cooling to 930°C. The final rolling temperature is 890°C, air-cooled to 505°C, and then slowly cooled to room temperature with the furnace.

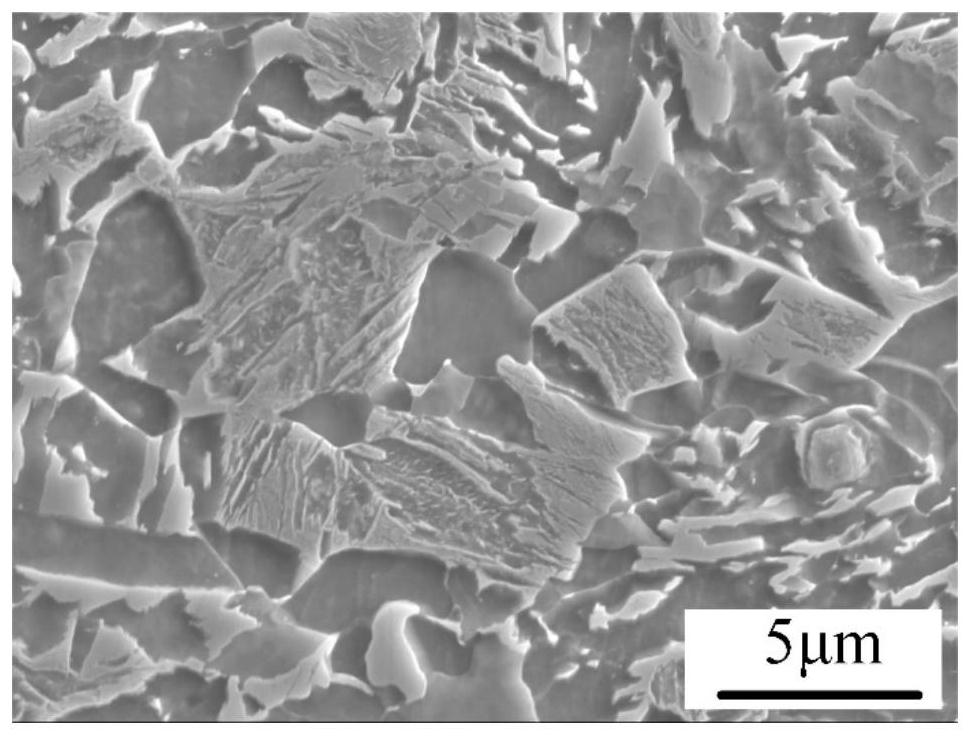

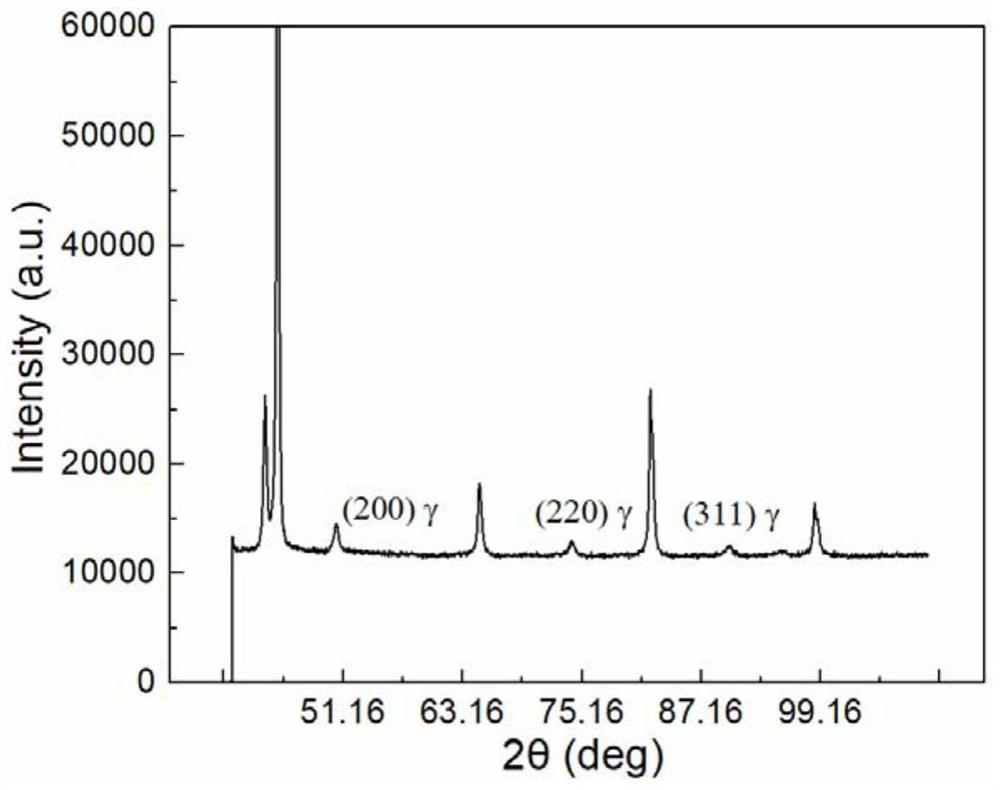

[0037] Its performance indicators are as follows after mechanical performance testing: yield strength is 680MPa, tensile strength is 1095MPa, elongation after fracture is 20.4%, and strong-plastic product is 22.338GPa.%. Such as figure 1 As shown, the metallographic structure is composed of ferrite, martensite / bainite and retained austenite, the volume fraction of ferrite is 14%, the volume fraction of retained austenite is 27.3%, and the rest is martensite b...

Embodiment 2

[0039]In this example, the composition of the hot-rolled Fe-Mn-Al-C steel quenched to the bainite zone to obtain the Q&P structure is: C: 0.23%, Mn: 3.1%, Al: 2.0%, and the rest is Fe.

[0040] After smelting and forging, the billet is heated to 1200°C and kept for 1.5 hours. Carry out the first stage rolling at 1180°C, then air cool to 925°C for the second stage rolling, the final rolling temperature is 880°C, air cool to 530°C, and then slowly cool to room temperature with the furnace.

[0041] Its performance indicators are as follows after mechanical performance testing: yield strength is 670MPa, tensile strength is 1070MPa, elongation after fracture is 21.2%, and strong-plastic product is 22.684GPa.%. The metallographic structure is composed of ferrite, martensite / bainite and retained austenite, the volume fraction of ferrite is 15%, the volume fraction of retained austenite is 25.4%, and the rest is martensite / bainite body.

Embodiment 3

[0043] In this example, the composition of the hot-rolled Fe-Mn-Al-C steel quenched to the bainite zone to obtain the Q&P structure is: C: 0.24%, Mn: 3.0%, Al: 2.2%, and the rest is Fe.

[0044] After smelting and forging, the billet is heated to 1210°C and kept for 1.5 hours. The first-stage rolling is carried out at 1180°C, and then the second-stage rolling is carried out by air cooling to 930°C. The final rolling temperature is 890°C, air-cooled to 545°C, and then slowly cooled to room temperature with the furnace.

[0045] Its performance indicators are as follows after mechanical performance testing: yield strength is 665MPa, tensile strength is 1055MPa, elongation after fracture is 22.1%, and strong-plastic product is 23.315GPa.%. The metallographic structure is composed of ferrite, martensite / bainite and retained austenite, the volume fraction of ferrite is 15%, the volume fraction of retained austenite is 26.7%, and the rest is martensite / bainite body.

[0046] The r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| strong plastic product | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com