Electric vehicle wheel side driving system and driving method

A driving system and wheel side technology, applied in the direction of motion deposition, power plant, vehicle components, etc., can solve the problems of difficult to meet normal dynamic requirements, complex driving system structure, single driving form, etc., to avoid mutual interference and ensure Output efficiency, compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049]The specific implementation manner of the present invention will be described in further detail below by describing the best embodiment with reference to the accompanying drawings.

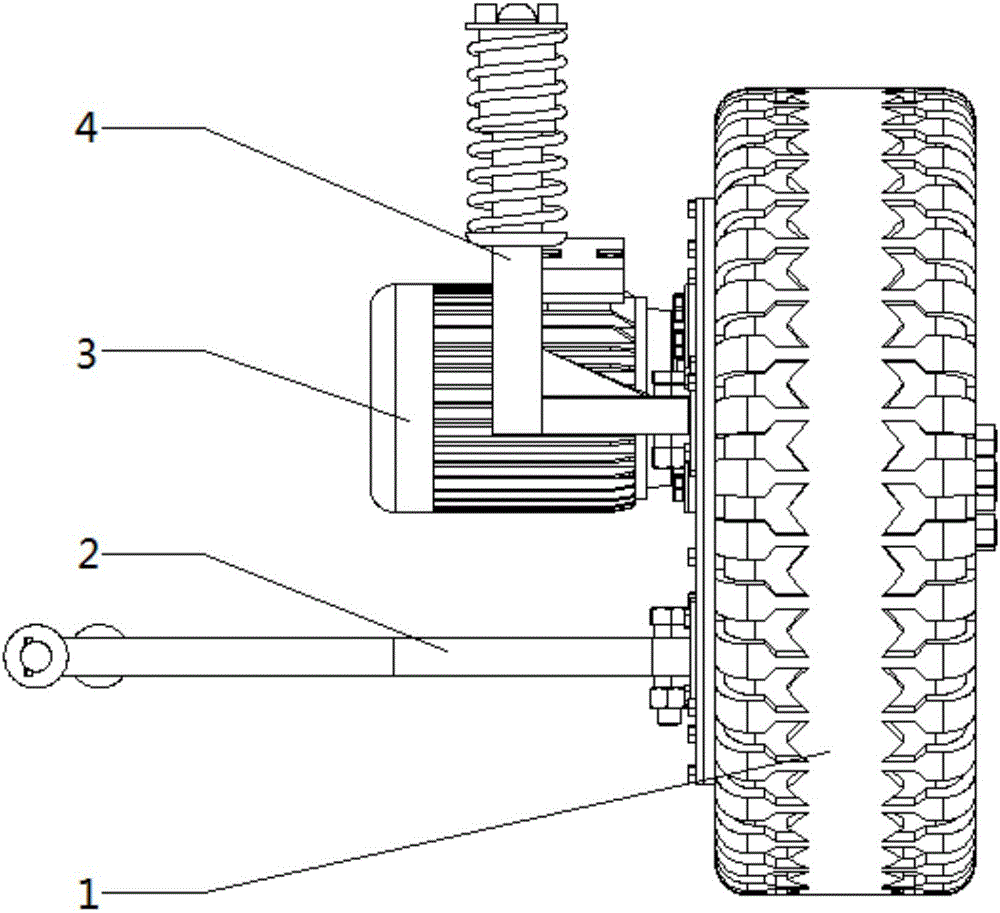

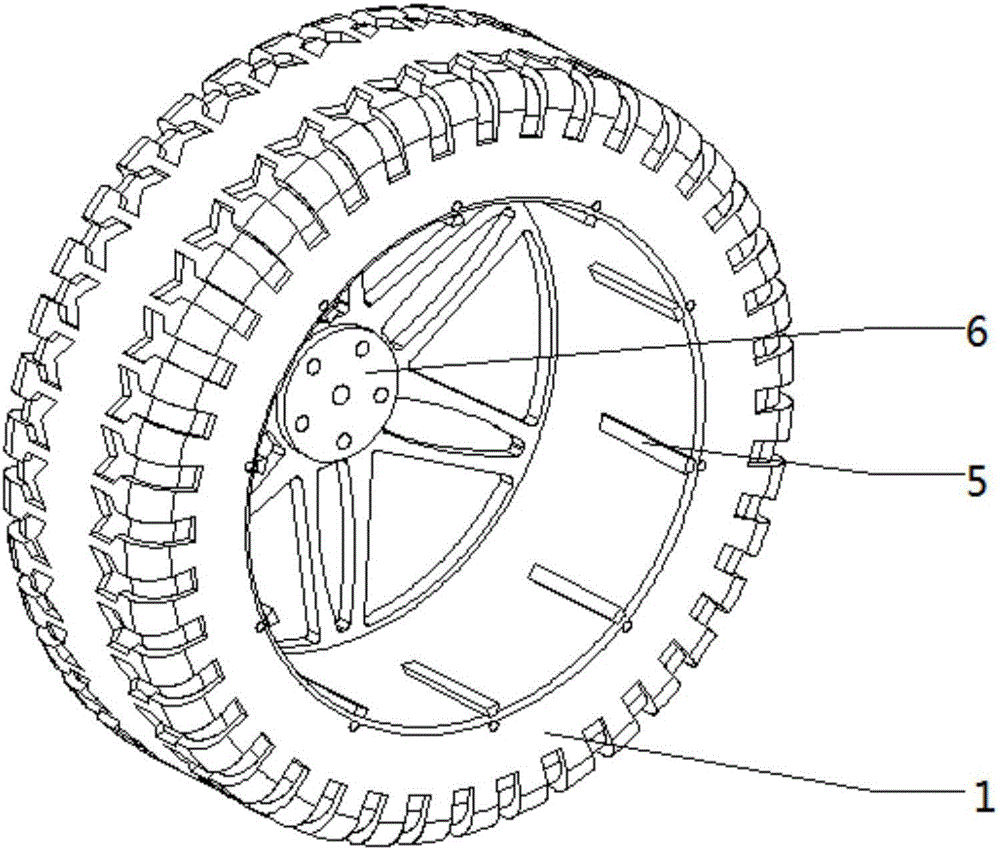

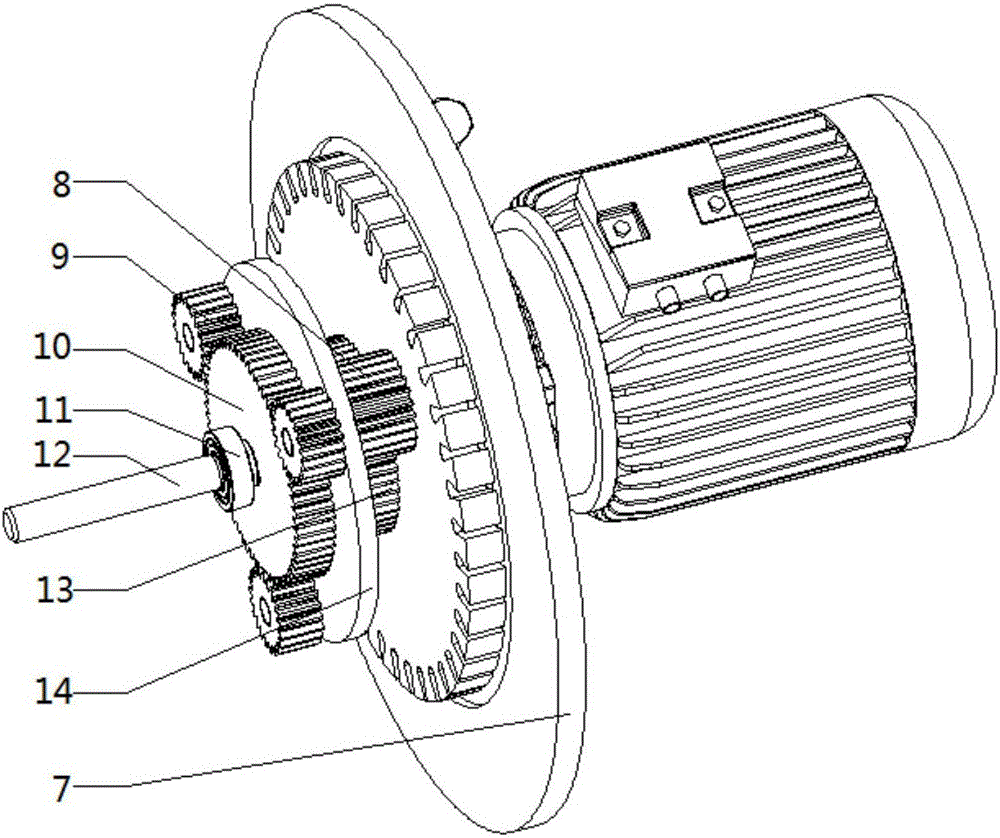

[0050] Such as figure 1 , Figure 17 and Figure 18 As shown, the electric wheel side drive system includes a deceleration drive system located in the wheel hub 1 and a direct drive system that directly drives the wheels with the wheel hub 1; the deceleration drive system and the direct drive system can be designed in different working conditions To ensure that the motors of each system work near the rated power, so as to ensure the output efficiency of the motors; the deceleration drive system and the direct drive system can also work under certain heavy load conditions (such as acceleration, climbing, and load) at the same time. In order to ensure that the electric vehicle has a strong driving force and acceleration performance; it can not only meet the normal power requirements and redu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com