Ink-jet apparatus and method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The inkjet technology using the start inkjet sign requires the cooperation of three parts: the inkjet device, the inkjet pattern and the inkjet method. The following examples and drawings are used to illustrate the content of the present invention.

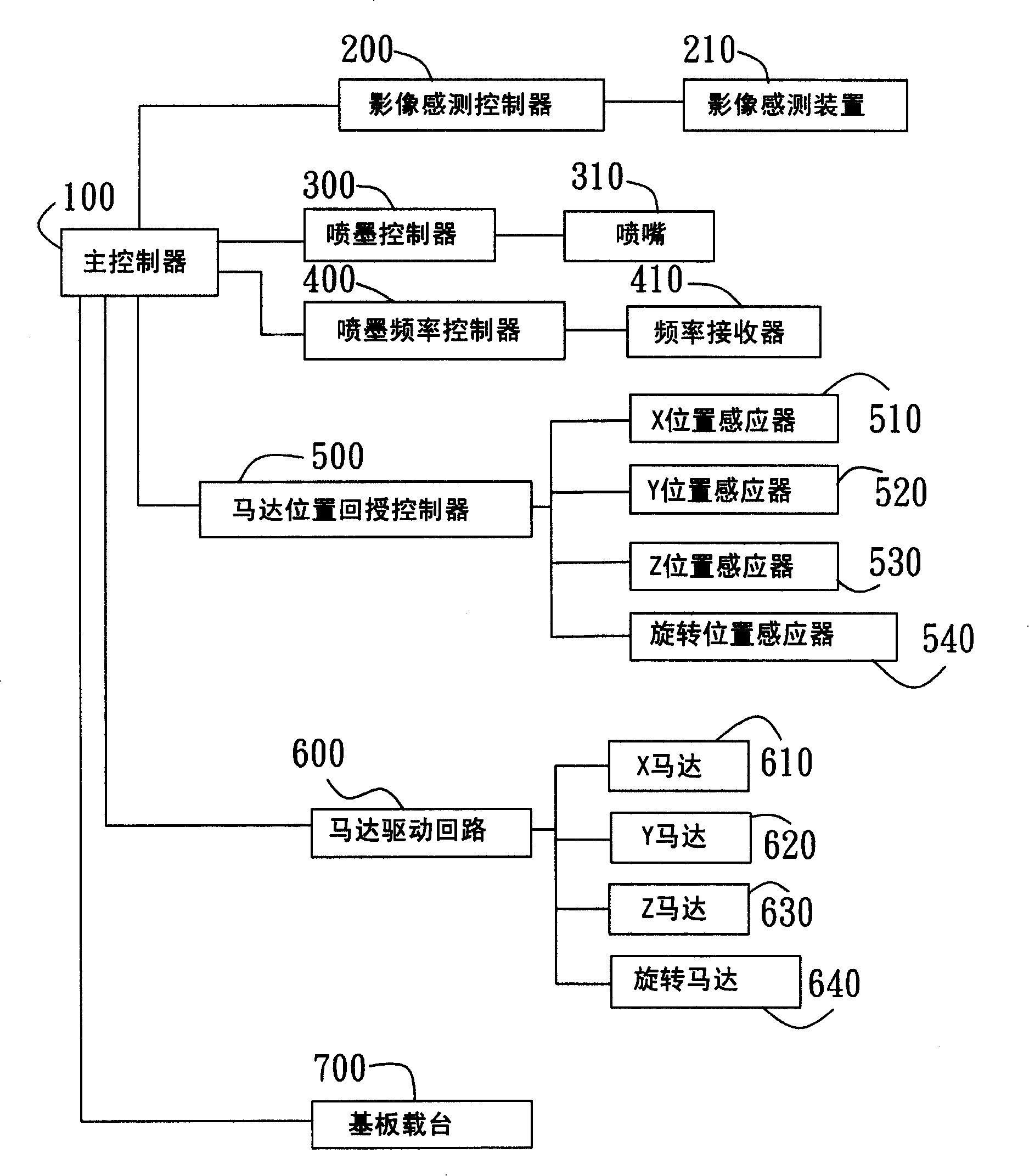

[0023] image 3 Shown is an inkjet device according to an embodiment of the present invention, the main controller 100 controls the entire inkjet action; the image sensing controller 200 is arranged between the image sensing device 210 and the main controller 100 to control the image sensing device 210 , the image sensing device 210 is used to capture the image of the inkjet pattern on the substrate. Secondly, the inkjet controller 300 is disposed between the nozzles 310 and the main controller 100 to control the nozzles 310 to perform inkjet behavior.

[0024] The inkjet frequency controller 400 is disposed between the frequency receiver 410 and the main controller 100 to control the frequency receiver 410 . The frequenc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com