Method and device for improving hydrogenation of silicon tetrachloride

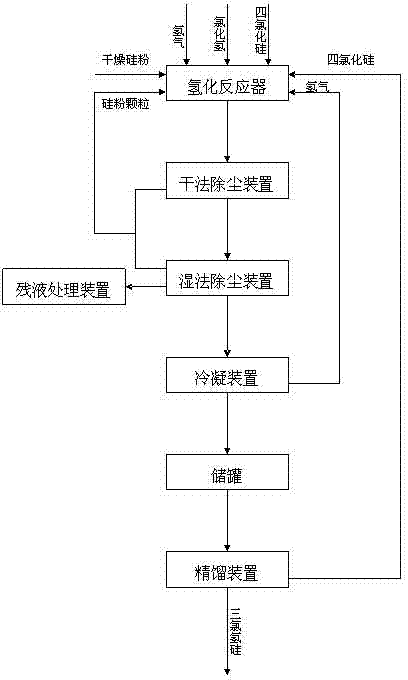

A technology of silicon tetrachloride and hydrogenation reactor, applied in the directions of halogenated silicon compounds, halogenated silanes, etc., can solve the problems of unsatisfactory impurity removal effect, high cost of reaction raw materials, etc., and achieve the effect of reducing complicated steps and reducing reaction cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0025] Embodiment: An improved method for hydrogenation of silicon tetrachloride, the method steps are as follows: (1) Metal silicon powder with an average particle size of 0.3-0.6 mm and a purity of 95-98% is heated to nitrogen gas by an external heating device 200-300°C, the heated nitrogen gas directly contacts the silicon powder without nickel catalyst to raise the temperature of the silicon powder to 200-300°C, and the heated and dried silicon powder is sent into the hydrogenation reactor through the pipeline. The height of the hydrogenation reactor is 2-3m.

[0026] (2) ① Vaporize and heat silicon tetrachloride through an external heating device, and the formation temperature is 500-550°C. silicon tetrachloride gas. ②Preheat the hydrogen chloride gas to 500-550°C through an external heating device. ③. Preheat the hydrogen to 500-550°C through the heater. Among them, silicon tetrachloride and hydrogen chloride are waste liquid and waste gas produced during the producti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com