Preparation method and application for ternary composite photocatalyst

A ternary composite and photocatalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve problems such as high cost and unsuitable for large-scale applications , to achieve short reaction time, excellent photocatalytic activity, and easy mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

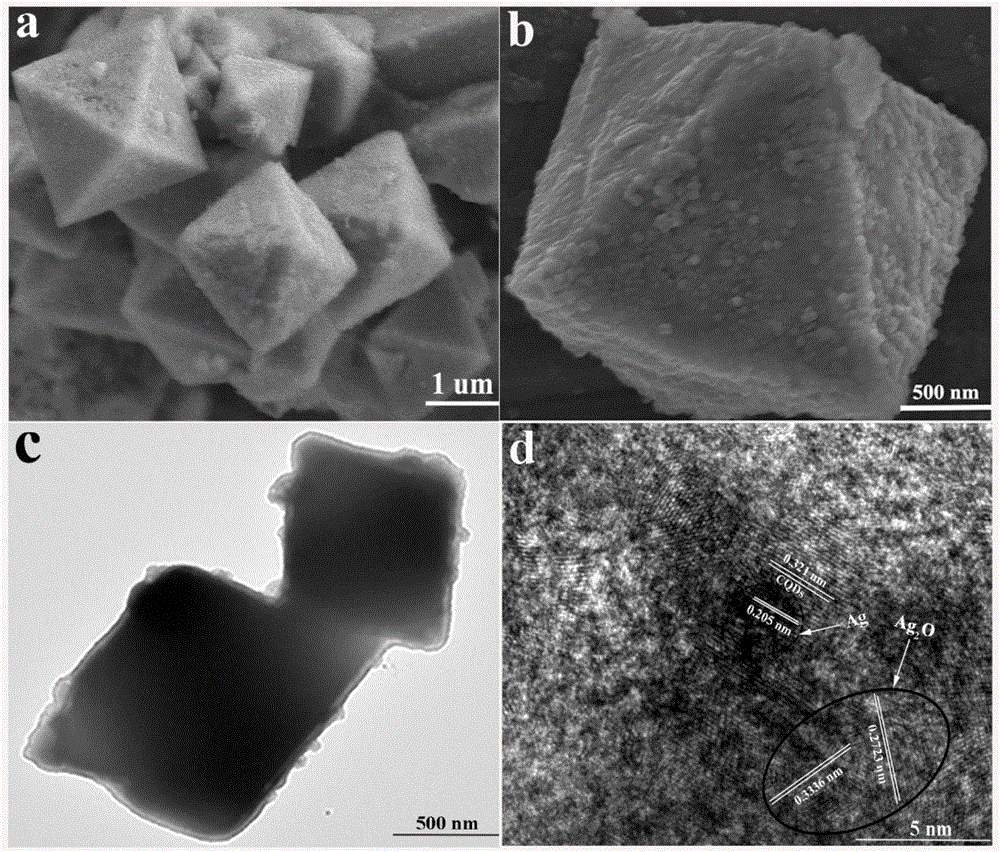

[0040] Preparation of Silver Oxide Nanoparticles with Octahedral Morphology

[0041] 1. Take 20ml of 1mol / L ammonium dihydrogen phosphate solution and add it dropwise to 10ml of 0.4mol / L silver nitrate solution to obtain solution A.

[0042] 2. Subsequently, the above solution A was adjusted to a pH value of 11 with 1 mol / L sodium hydroxide, and a black suspension B was gradually obtained.

[0043] 3. Fully stir the above black suspension B for 10 minutes, let stand, and centrifuge for 10 minutes to obtain a black solid. Alternately washed three times with deionized water and ethanol, and vacuum dried at 60 °C for 24 hours to obtain the sample Ag 2 O.

Embodiment 2

[0045] 0.5wt% CQDs / Ag 2 Preparation of O

[0046] 1. Preparation of carbon quantum dots

[0047] 1. Dissolve 0.05mol of glucose in 50ml of water to form a uniform and stable aqueous solution A.

[0048] 2. Take 50ml of 1mol / L sodium hydroxide solution and slowly add it to aqueous solution A to obtain solution B, then place the above solution B in an ultrasonic cleaner for 3 hours to obtain solution C containing carbon quantum dots, and then dialyze to obtain the diameter A carbon quantum solution with a particle size of 5-10nm.

[0049] 3. The above carbon quantum dot solution was freeze-dried for 24 hours to obtain carbon quantum dot powder.

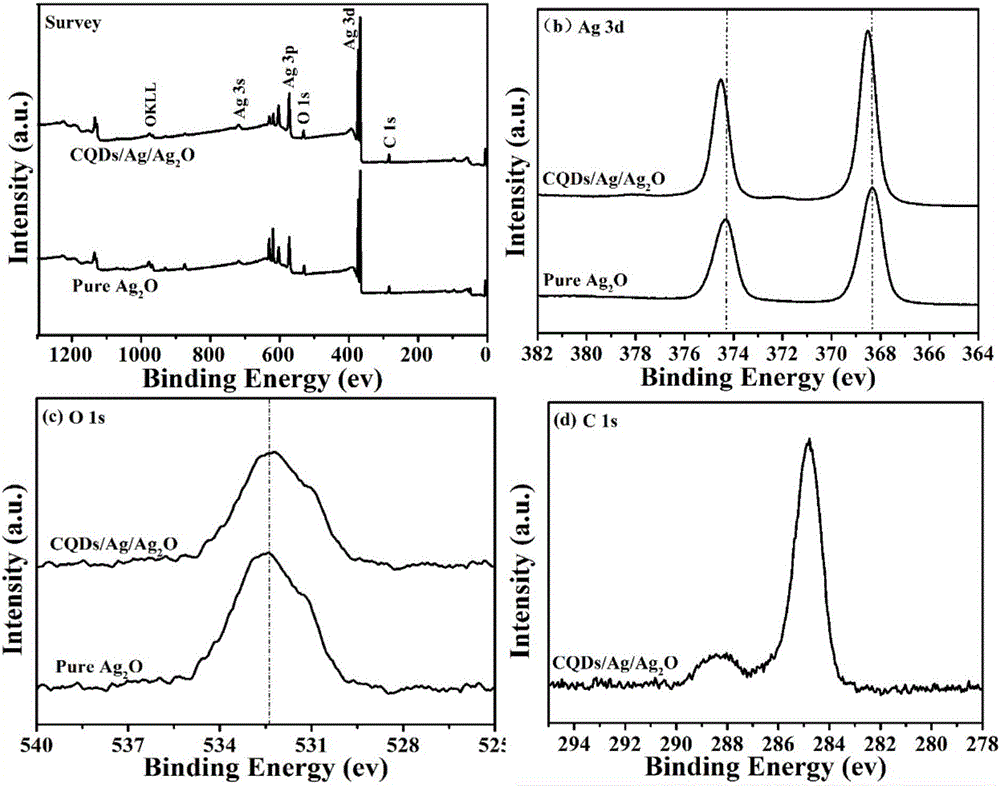

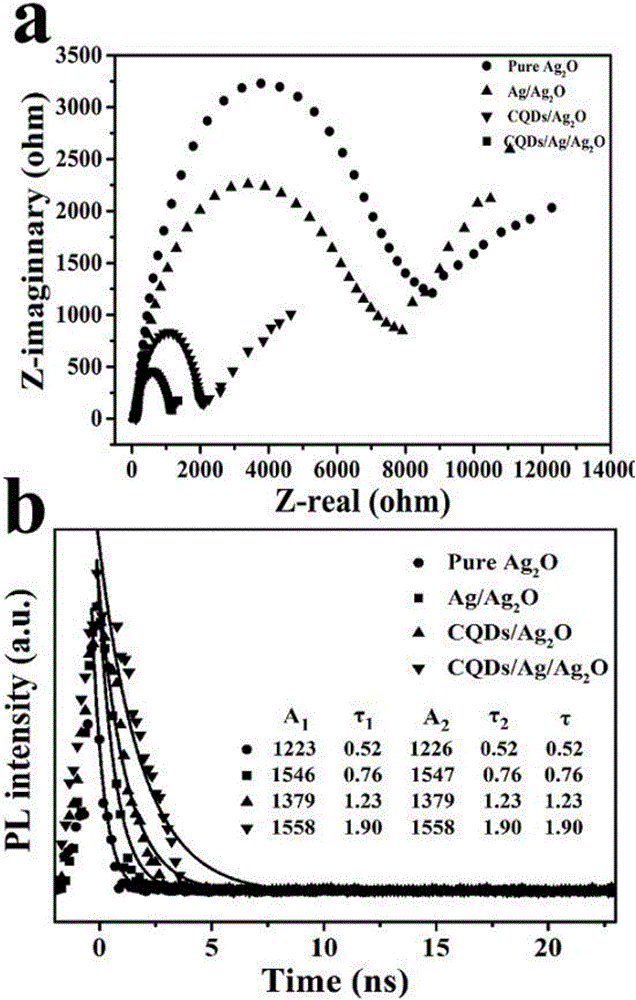

[0050] 2. Preparation of carbon quantum dots modified octahedral silver oxide

[0051] 1. Dissolve 2.3mg of carbon quantum dots in 20ml of 1mol / L ammonium dihydrogen phosphate solution to form solution D, add solution D dropwise to 10ml of 0.4mol / L silver nitrate solution, and stir thoroughly for 10 minutes to obtain solution E . ...

Embodiment 3

[0054] Ag / Ag with photodeposition time of 2h 2 Preparation of O

[0055] 1. Preparation of octahedral silver oxide

[0056] 1. Take 20ml of 1mol / L ammonium dihydrogen phosphate solution and add it dropwise to 10ml of 0.4mol / L silver nitrate solution to obtain solution A.

[0057] 2. Then adjust the pH value of the above solution A to 11 with 1mol / L sodium hydroxide, and gradually obtain a black suspension B.

[0058] 2. Put the black suspension B under a 250W UV lamp for 2 hours under vigorous stirring, then stand still and centrifuge for 10 minutes to obtain a black solid, which is washed alternately with deionized water and ethanol three times, and dried in vacuum at 60°C for 24 hours. Finally get Ag / Ag 2 O samples.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com