Catalyst-absorbent complex for absorbing and strengthening low-carbon hydrocarbon steam reforming hydrogen and preparing method of complex

A technology for steam reforming and absorption enhancement, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve obstacles to rapid and full absorption of CO2, catalysts and Absorbent does not achieve uniform mixing and other problems, to achieve the effect of reducing complicated steps, good absorption performance and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

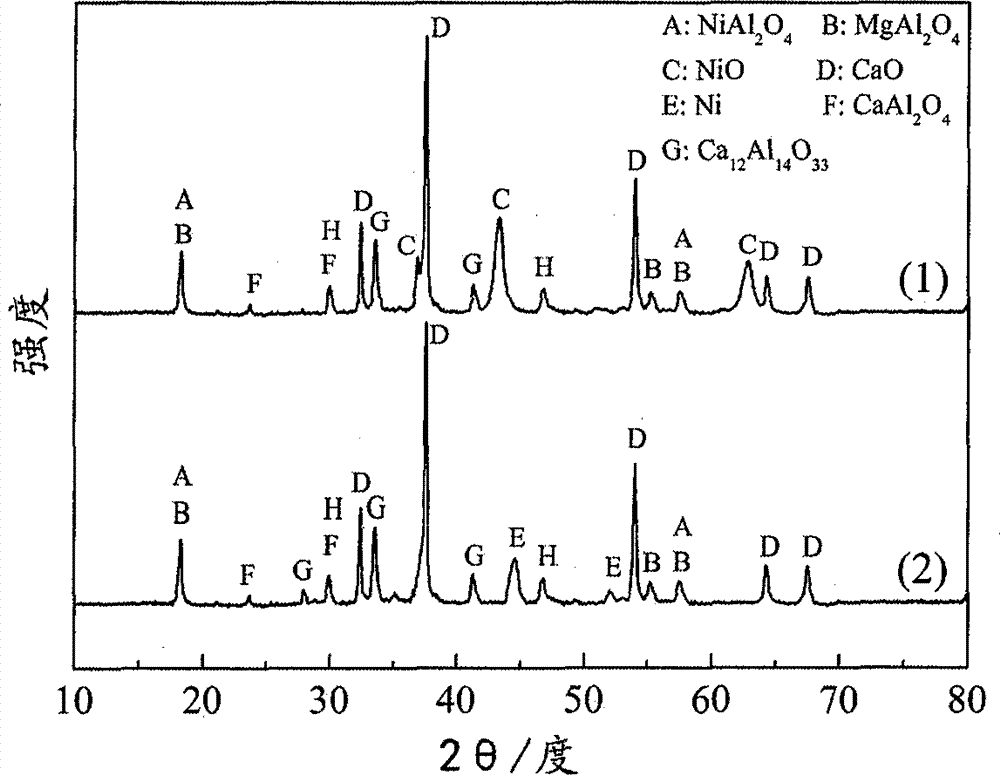

[0034] At room temperature, 2.49g Ni(CH 3 COO) 2 ·6H 2 O, 3.85g Mg(NO 3 ) 2 ·6H 2 O, 8.81gCa(CH 3 COO) 2 ·H 2 O and 9.38g Al(NO 3 ) 3 ·9H 2 O was dissolved in a beaker to make a 100mL solution. Weigh 8.00g NaOH and 1.33g Na 2 CO 3 , Use a beaker to add water to dissolve and prepare a 100mL solution. Under stirring conditions, the above two mixed solutions were added dropwise to the four-necked flask at the same speed (50mL / h) with a micro-syringe pump for 2 hours, during which the pH value of the solution was adjusted to about 10. Then the obtained suspension was aged at 60°C for 12h, and then taken out and filtered and washed. The obtained light green precipitate was dried at 100°C for 12h to obtain a light green blocky solid. Finally, after grinding, it was calcined in a muffle furnace at 850°C for 5 hours to obtain catalyst-absorbent composite A. The content of each element is shown in Table 1, and the X-ray diffraction patterns before and after calcining are shown in Table ...

Embodiment 2

[0036] At room temperature, 2.18g Ni(NO 3 ) 2 ·6H 2 O, 3.21g Mg(NO 3 ) 2 ·6H 2 O, 9.69g Ca(CH 3 COO) 2 ·H 2 O and 9.38g Al(NO 3 ) 3 ·9H 2 O was dissolved in a beaker to make a 100mL solution. Weigh 8.00g NaOH and 1.33g Na 2 CO 3 , Use a beaker to add water to dissolve and prepare a 100mL solution. Under stirring conditions, the above two mixed solutions were added dropwise to the four-necked flask at the same speed (50mL / h) with a micro-syringe pump for 2 hours, during which the pH value of the solution was adjusted to about 10. Then the resulting suspension was aged for 8 hours at 60°C, and then taken out and filtered and washed. The obtained light green precipitate was dried at 100°C for 12 hours to obtain a light green blocky solid. Finally, it was ground and calcined in a muffle furnace at 850°C for 5 hours to obtain the catalyst-absorbent composite B. The content of each element is shown in Table 1.

Embodiment 3

[0038] At room temperature, add 2.91g Ni(NO 3 ) 2 ·6H 2 O, 3.59g Mg(NO 3 ) 2 ·6H 2 O, 6.34g Ca(CH 3 COO) 2 ·H 2 O and 7.50g Al(NO 3 ) 3 ·9H 2 O was dissolved in a beaker to make a 100mL solution. Weigh 6.00g NaOH and 1.03g Na 2 CO 3 , Use a beaker to add water to dissolve and prepare a 100mL solution. Under stirring conditions, the above two mixed solutions were added dropwise to the four-necked flask at the same speed (50mL / h) with a micro-syringe pump for 2 hours, during which the pH value of the solution was adjusted to about 10. Then the obtained suspension was aged at 60°C for 12h, and then taken out and filtered and washed. The obtained light green precipitate was dried at 100°C for 12h to obtain a light green blocky solid. After the final grinding, it was calcined in a muffle furnace at 900°C for 4 hours to obtain a catalyst-absorbent composite C. The content of each element is shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com