Method for reclaiming solvent from aramid fiber polymeric compound

A technology for recovering solvents and polymers, which is used in the recovery of high-value solvents and additives, and in the field of solvent recovery from aramid polymers, can solve the problems of low quality of recovered solvents and complicated processes, and achieve clean production, simplified and efficient operation. , the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

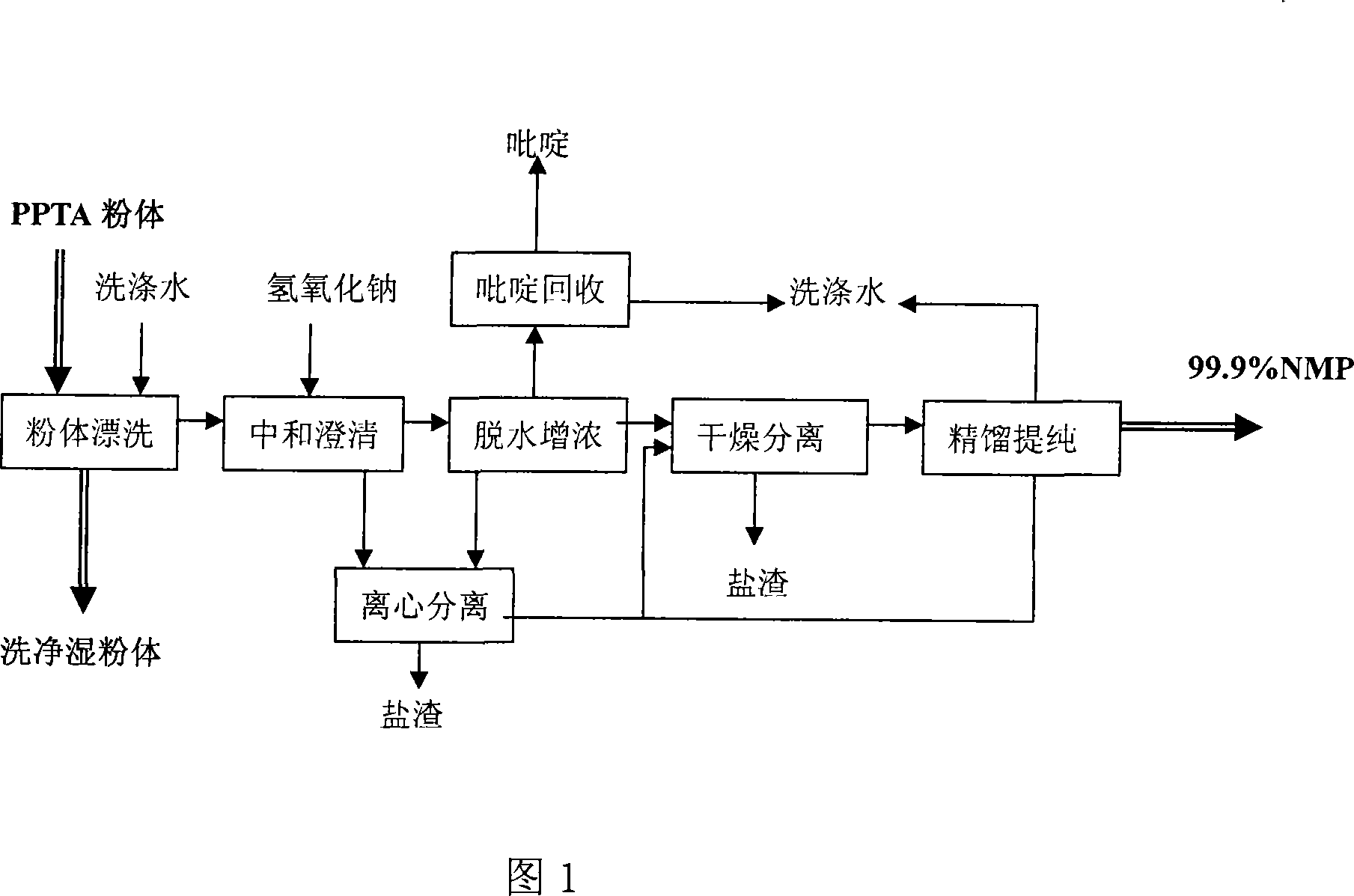

[0024] The present invention will be further described below in conjunction with the accompanying drawings and embodiments. As shown in Figure 1.

[0025] A method for reclaiming a solvent from an aramid polymer, comprising the steps of:

[0026] Powder rinse:

[0027] The aramid polymer powder is mixed evenly with the washing liquid under stirring, filtered, and 100 parts of the powder are repeatedly washed with 60-400 parts of washing water, and placed in the washed powder. The clean powder is used to prepare para-aramid. The washing liquid obtained by filtration becomes the raw material for solvent recovery.

[0028] Neutralize and clarify:

[0029] Use sodium hydroxide or sodium carbonate to neutralize the washing solution, clarify and filter to remove precipitated impurities, and obtain a clarified or filtered neutralized supernatant.

[0030] Dehydration and enrichment:

[0031] The neutralized solution is distilled and dehydrated under normal pressure conditions to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com