Colored ceramic ink powder for mass-polymerization architectural ceramic and preparation method thereof

A technology of architectural ceramics and bulk polymerization, which is applied in the field of ceramic printing, can solve the problems of irregular shape of toner particles, inability to print high-resolution images, and high cost of high-quality color pictures, and achieve fine particle appearance, large market prospects and Effects of Economic Value, High Level Contrast and Developing Density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

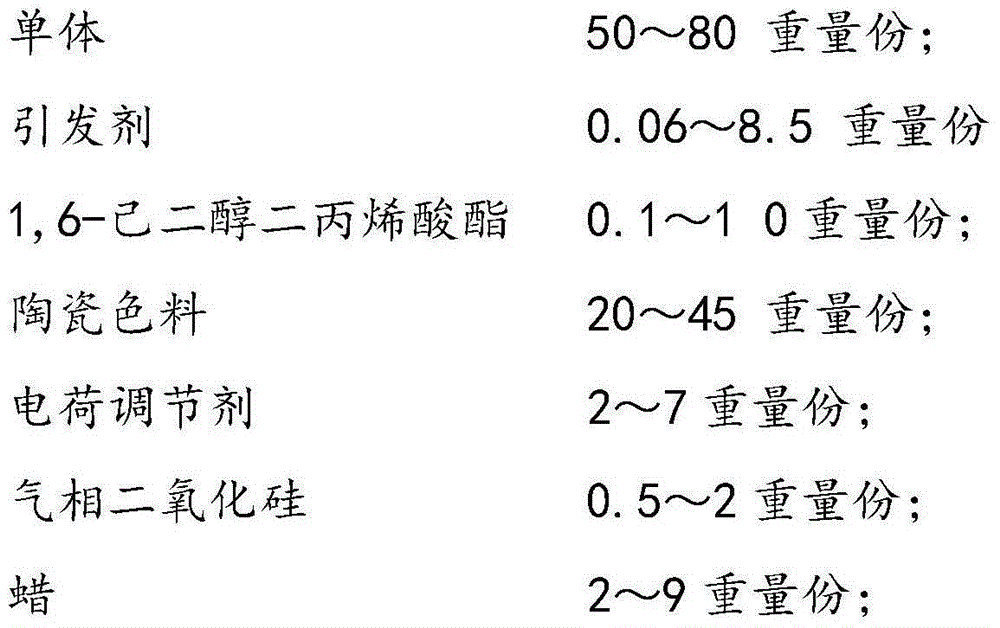

[0022] Example 1 This example discloses a bulk polymerized color ceramic toner for architectural ceramics, which includes the following components:

[0023]

[0024] Wherein, the monomers include acrylic ester compounds and styrene monomers, the weight ratio of the two is 1:4-6, and the monomers are polymerized in bulk to form a binder resin. By adjusting the ratio between the monomer components, The glass transition temperature of the resulting resin is 65-95°C, and the softening temperature is 100-160°C.

[0025] The initiator is a compound initiator composed of a low-temperature initiator and a high-temperature initiator.

[0026] The initiator is an azo initiator, or a peroxide initiator, or a mixture of an azo initiator and a peroxide initiator.

[0027] The azo initiator includes azobisisobutyronitrile AIBN, azobisisoheptanonitrile and dimethyl azobisisobutyrate;

[0028] The peroxide initiator includes: benzoyl peroxide BPO, benzoyl tert-butyl peroxide TBPB, 2-ethy...

Embodiment 2

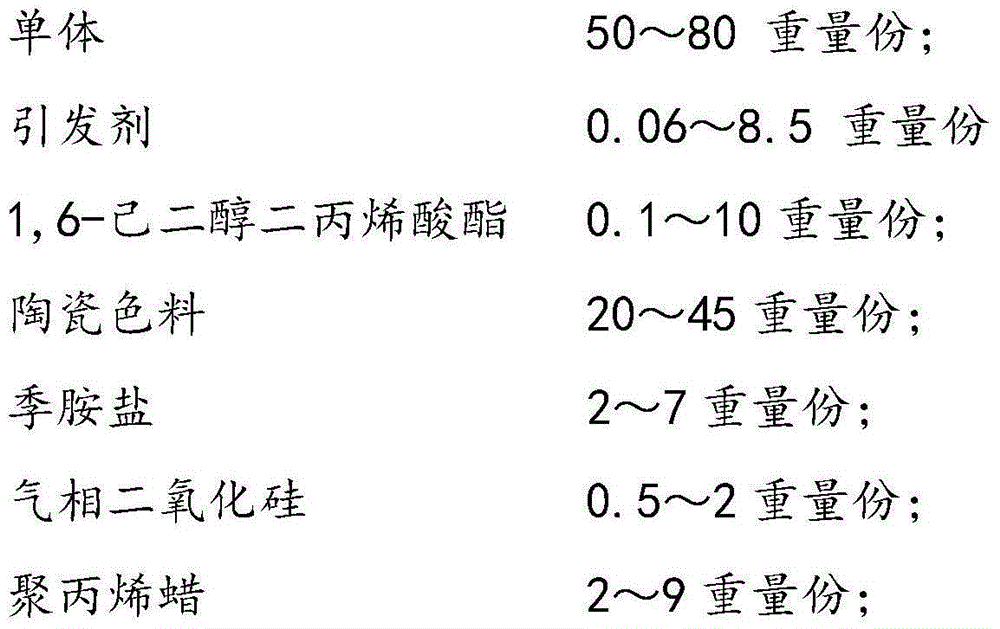

[0029] Example 2 This example discloses a bulk polymerized color ceramic toner for architectural ceramics, which includes the following components:

[0030]

[0031] Wherein, the monomers include acrylic ester compounds and styrene monomers, the weight ratio of the two is 1:5, and the monomers are polymerized in bulk to form a binder resin. By adjusting the ratio between the monomer components, the resulting The resin has a glass transition temperature of 80°C and a softening temperature of 130°C.

Embodiment 3

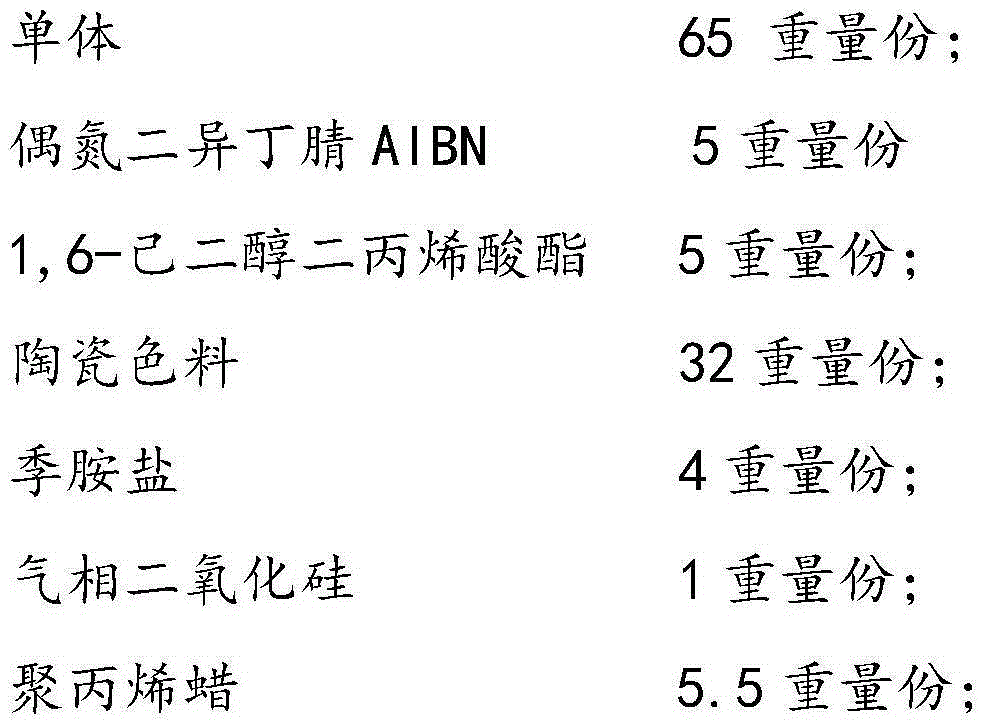

[0032] Example 3 This example discloses a bulk polymerized color ceramic toner for architectural ceramics, which includes the following components:

[0033]

[0034] Wherein, the monomer includes lauryl methacrylate and styrene monomer, and the weight ratio of the two is 1:6. The monomers are bulk polymerized to form a bonding resin, and the glass transition temperature of the resulting resin is 65° C., and the softening temperature is 160° C. by adjusting the ratio of the monomer components.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com