Method for preparing water-repellent polyester fibers

A technology of polyester fiber and water repellent, which is applied in the direction of fiber type, fiber treatment, melt spinning, etc., and can solve the problems of increased processing procedures, complexity, and high production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Experimental material

[0044] In an exemplary embodiment of the present invention, the following experimental raw materials are used:

[0045] PET polyester chips: IV: 0.65dl / g; moisture content after crystallization and drying is below 50ppm;

[0046] Spinning oil: polyester fiber spinning oil, produced in Takemoto, Japan

[0047] Water-repellent agent: Suzhou Yuanrui fluorine-based water-repellent agent, brand name; UNIDYEN TG-823

[0048] Bridging agent: Suzhou Yuanrui isocyanic acid bridging agent, brand; FARAGENT CL-324

[0049] Antistatic agent: Suzhou Yuanrui polyester fiber antistatic agent.

[0050] Water: deionized water.

[0051] Preparation Process:

[0052] Prepare a certain amount of water-repellent treatment liquid, weigh 320g of water-repellent agent, 40g of bridging agent, 40g of antistatic agent, and 80g of spinning oil, add water to a total volume of 1L, put it in a container, and stir well. The prepared water-repellent treatment solution is in...

Embodiment 2

[0067] The types and grades of raw materials used are the same as in Example 1, and the processing technology is the same as in Example 1, except that the water repellent dosage is changed to 160g, the bridging agent is 20g, the antistatic agent is 40g, and the spinning oil is 80g, and water is added to make the total volume 1L

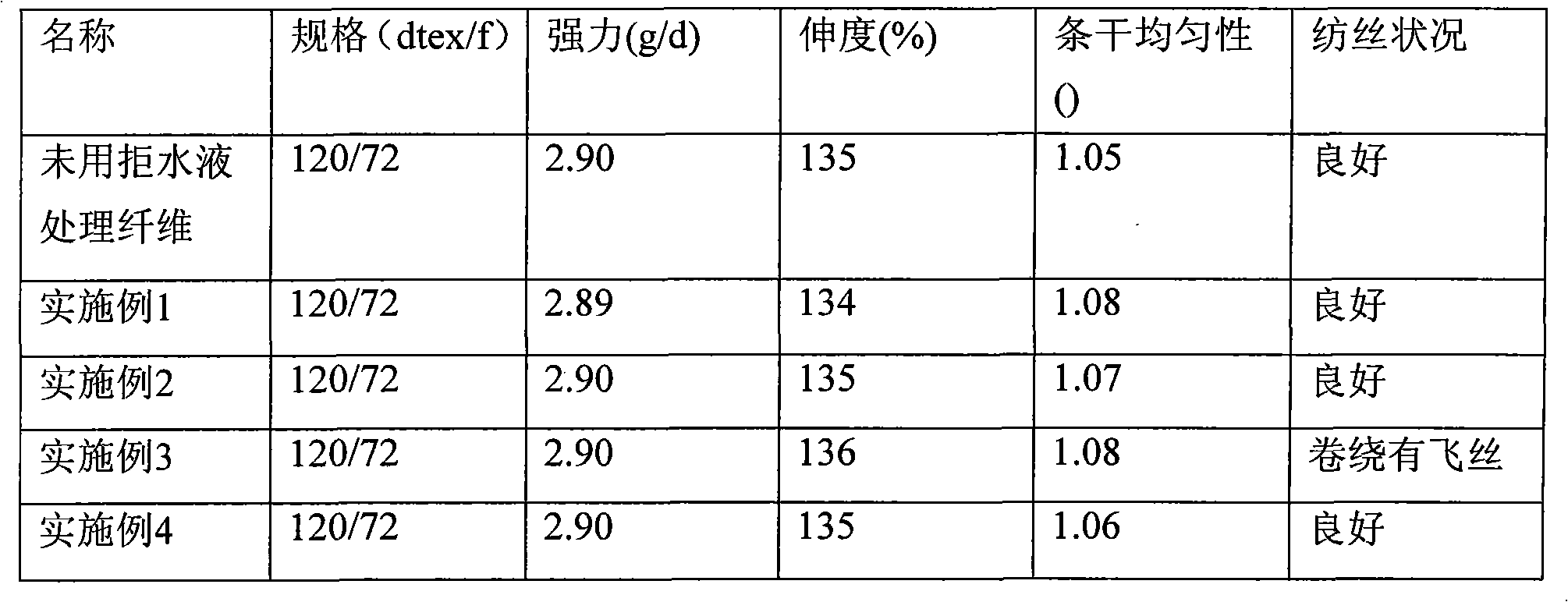

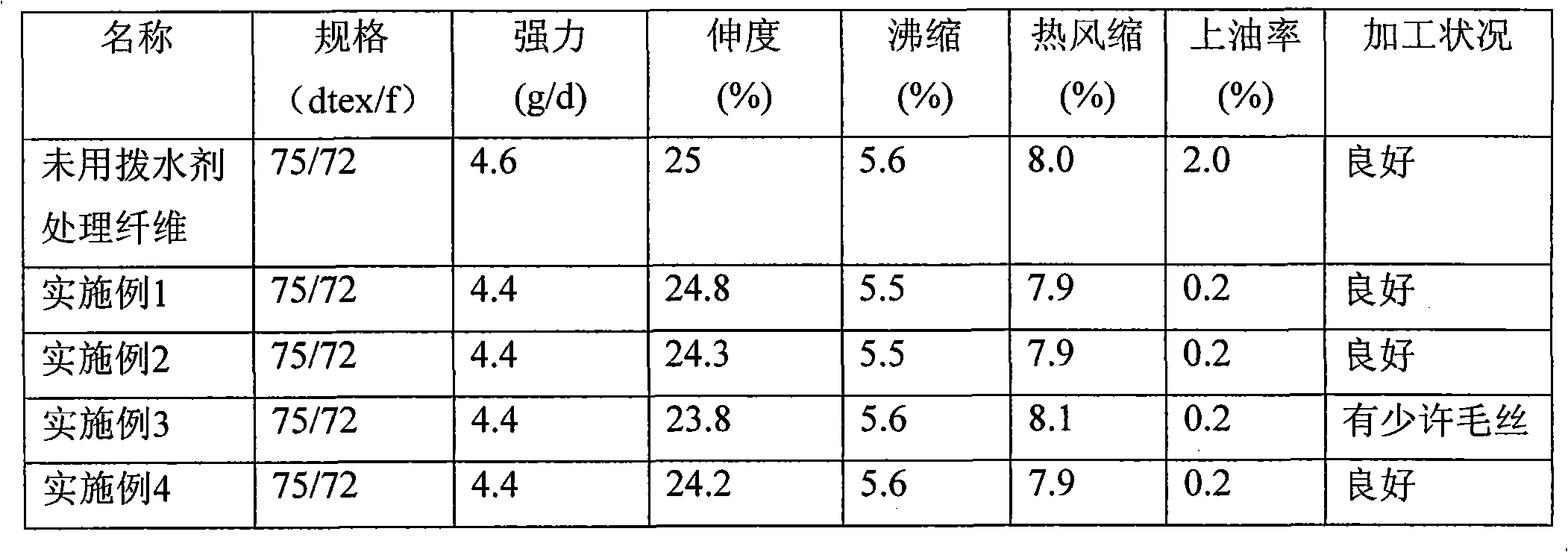

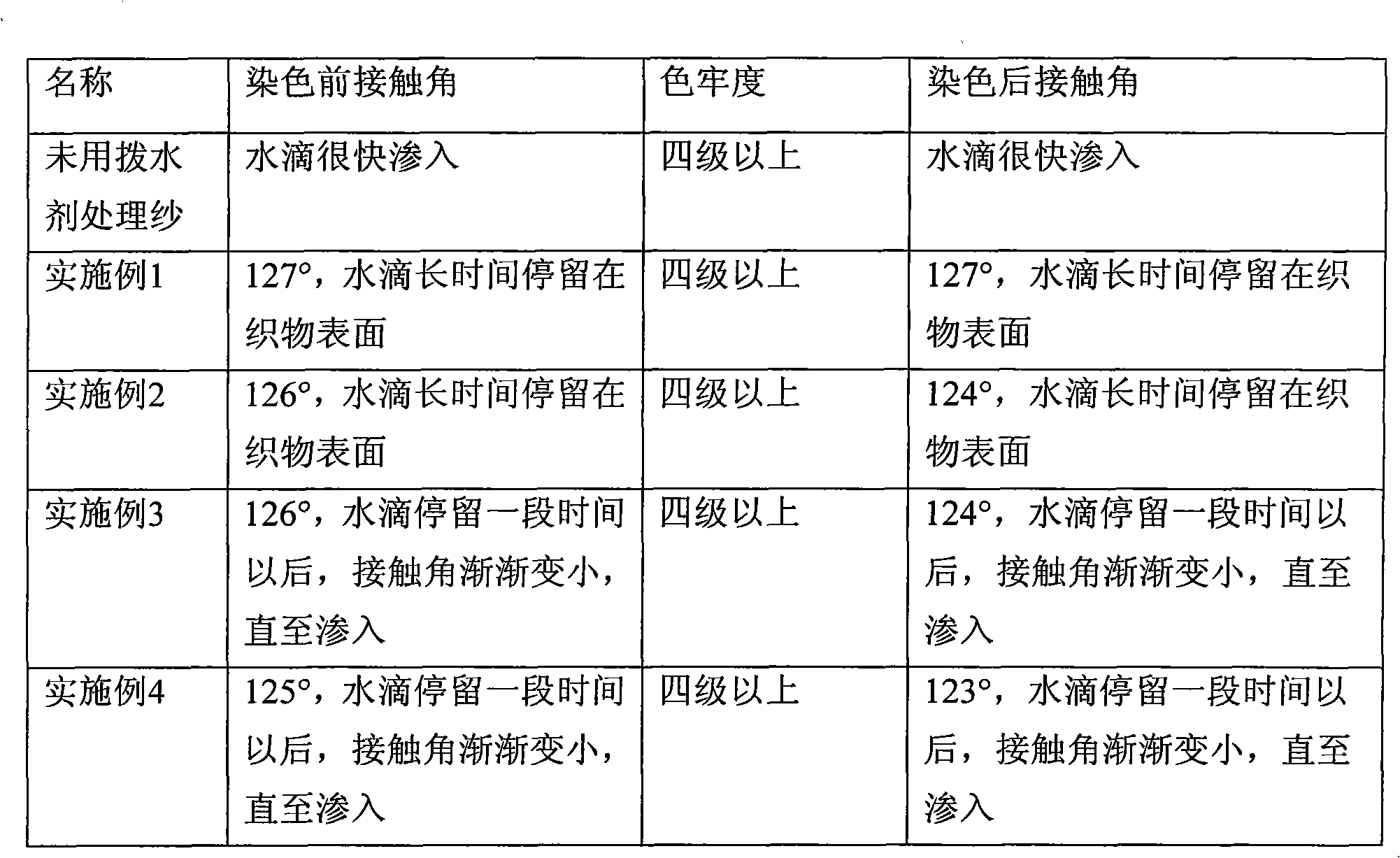

[0068] Product test results are shown in Table 1, Table 2 and Table 3.

Embodiment 3

[0070]The types and grades of raw materials used are the same as in Example 1, and the processing technology is the same as in Example 1, except that the amount of water repellent is changed to 80g, the bridging agent is 10g, and the spinning oil is 80g. Water is added to make the total volume 1L, and antistatic is not added. agent

[0071] Product test results are shown in Table 1, Table 2 and Table 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com