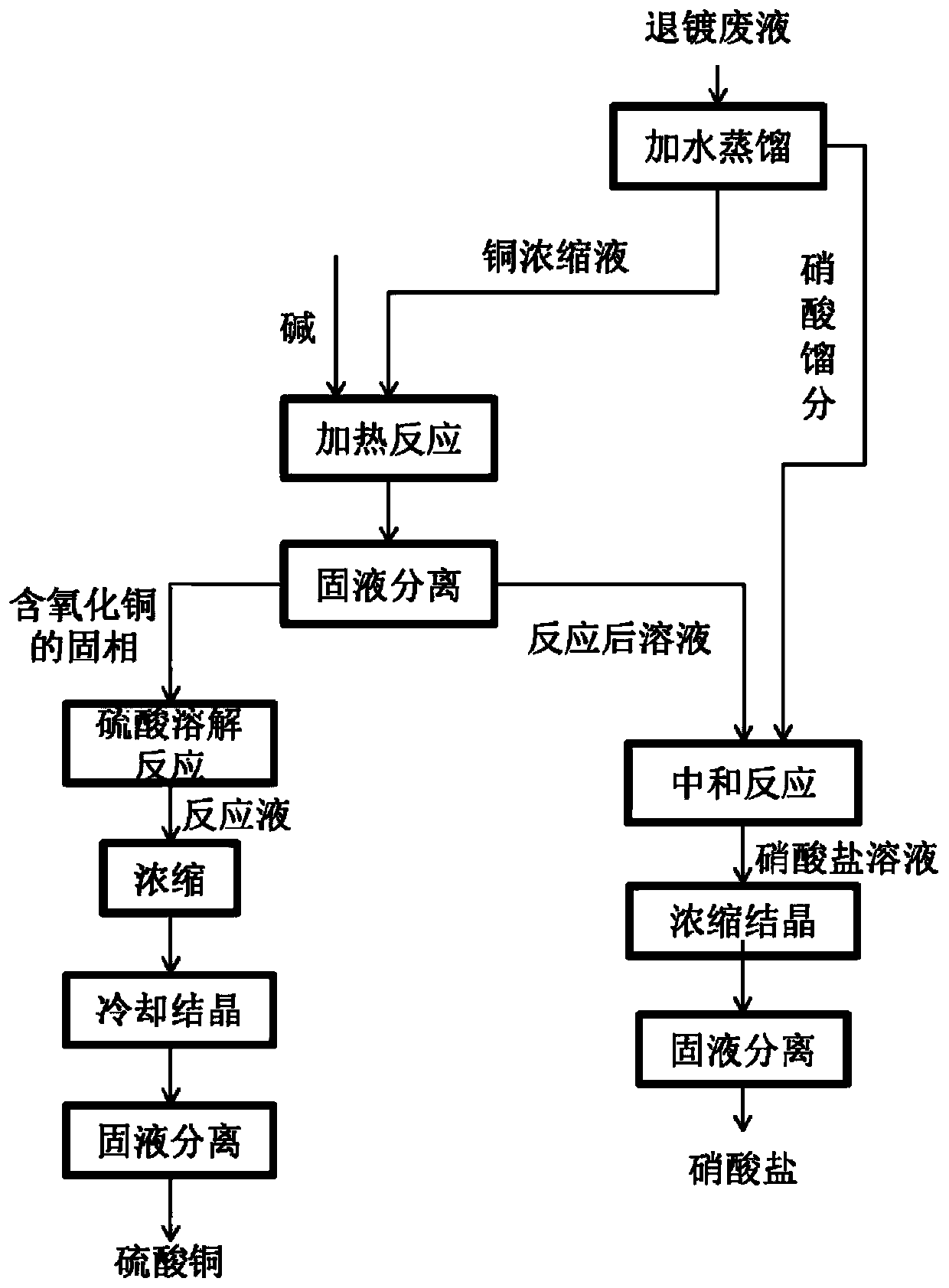

Printed circuit board stripping waste liquid treatment method

A technology for printed circuit boards and stripping waste liquid, which is applied in the fields of metallurgical wastewater treatment, heating water/sewage treatment, neutralization water/sewage treatment, etc. Waste liquid treatment process and other issues, to achieve the effect of fast cooling and crystallization, conducive to subsequent separation operations, and fine particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

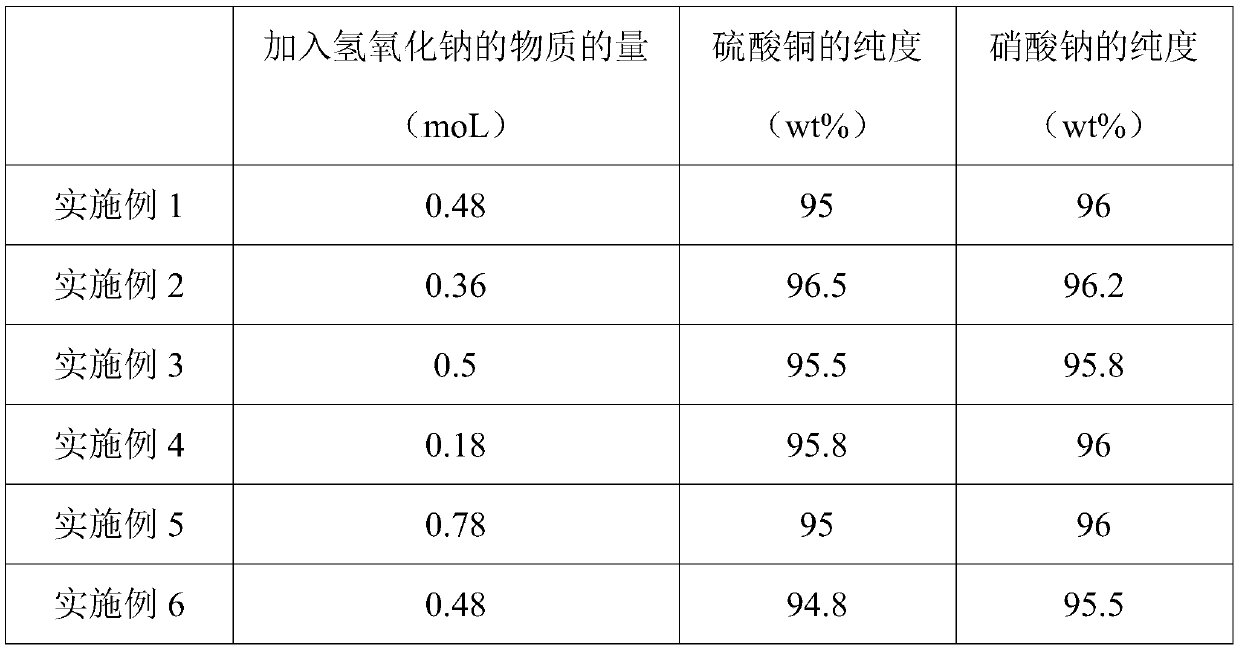

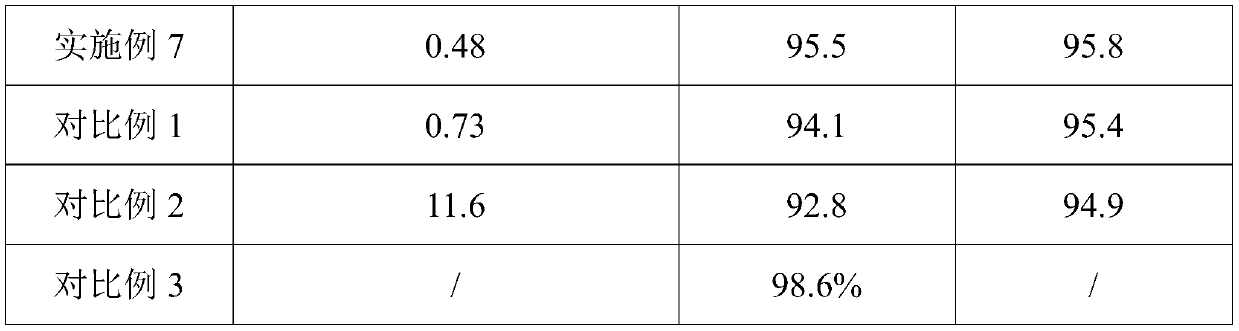

Embodiment 1

[0081] This embodiment provides a method for treating waste liquid deplating of printed circuit boards, the method comprising the following steps:

[0082] (1) Get 5L of the PCB deplating waste liquid of a certain electronics factory, wherein the nitric acid content is 12wt%, and the copper content is 6g / L, mix the waste liquid, negative pressure distillation under 120 ℃,-0.04MPa, divide in the distillation process Section detects the mass concentration of nitric acid in the nitric acid fraction, and supplements with water, concentrates to 500mL and when the mass concentration of nitric acid in the nitric acid fraction obtained by the last detection is 5wt%, stop the distillation to obtain a copper concentrate with a mass concentration of nitric acid of 4wt%. And the mass concentration of nitric acid is the nitric acid fraction of 10wt%, and the volume ratio of described waste liquid and total adding water is 2.58:1;

[0083] (2) Add 50 mL of tap water to the above-mentioned c...

Embodiment 2

[0088] This embodiment provides a method for treating waste liquid deplating of printed circuit boards, the method comprising the following steps:

[0089] (1) Take 5L of PCB deplating waste liquid from an electronics factory, wherein the nitric acid content is 20wt%, and the copper content is 10g / L, mix the waste liquid and water, and carry out negative pressure distillation at 118°C and -0.04MPa. Detect the mass concentration of nitric acid in the nitric acid fraction in the middle section, and add water, concentrate to 500mL and when the mass concentration of nitric acid in the nitric acid fraction obtained by the last detection is 4.5wt%, stop distillation, and the mass concentration of nitric acid obtained is 3wt%. The mass concentration of copper concentrated solution and nitric acid is the nitric acid fraction of 18wt%, and the volume ratio of described waste liquid and total water added is 3.25:1;

[0090] (2) Add 50ml of tap water to the above concentrated solution, a...

Embodiment 3

[0095] This embodiment provides a method for treating waste liquid deplating of printed circuit boards, the method comprising the following steps:

[0096](1) Take 5L of PCB deplating waste liquid from an electronics factory, wherein the nitric acid content is 10wt%, and the copper content is 5g / L, mix the waste liquid and water, and carry out negative pressure distillation at 115°C and -0.05MPa. Detect the mass concentration of nitric acid in the nitric acid fraction in the middle section, and add water, concentrate to 500mL and when the mass concentration of nitric acid in the nitric acid fraction obtained by the last detection is 5.5wt%, stop distillation, and the mass concentration of nitric acid obtained is 1wt%. The mass concentration of copper concentrated solution and nitric acid is the nitric acid fraction of 8wt%, and the volume ratio of described waste liquid and total water added is 2:1;

[0097] (2) Add 50ml of tap water to the above-mentioned concentrated solutio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com