Method for preparing and purifying propyl acetate

A technology of propyl acetate and n-propyl acetate, which is applied in the field of preparation and purification of propyl acetate, can solve the problems of separation and purification difficulty of esterification liquid, and achieve the effect of continuous separation and purification and continuous esterification reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

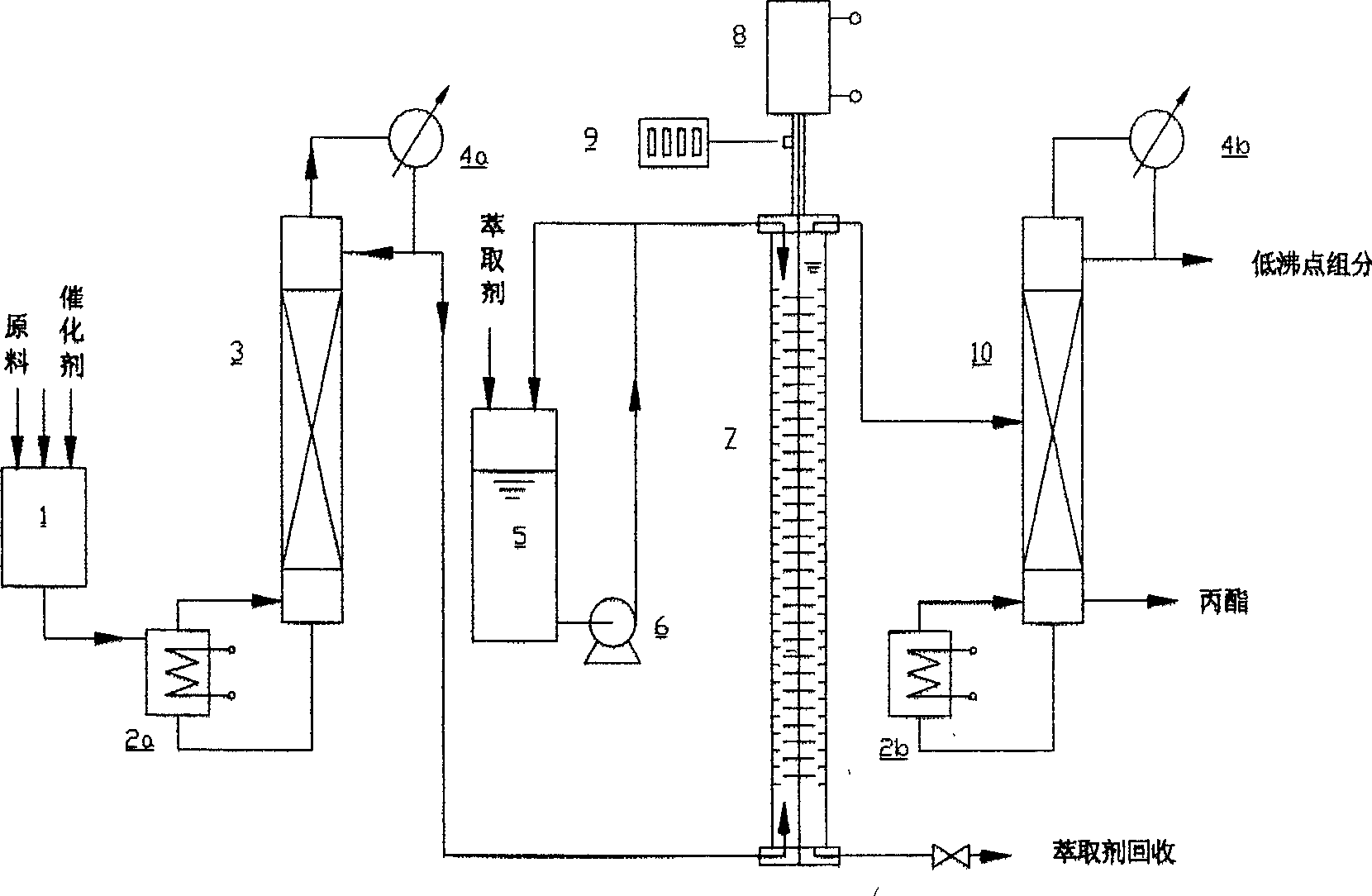

Image

Examples

Embodiment 1

[0016] Acetic acid, n-propanol and concentrated sulfuric acid are preset in the esterification kettle, and the temperature is raised for reaction. To stabilize the temperature at the top of the esterification tower at 82°C, control the reflux ratio to 4-5. Then, acetic acid, n-propanol and sulfuric acid pass through the pre-reactor continuously according to the ratio, and then enter the esterification tank for esterification. Add about 100ml of about 95% crude ester obtained from the top of the esterification tower and distilled water into a 250ml stoppered Erlenmeyer flask, put it in a constant temperature water bath shaker at 25°C, shake for 0.5-1 hour, and analyze the ester phase after standing still for 0.5 hours and water phase. Add a certain amount of saturated magnesium chloride salt solution to the ester phase, put it into a constant temperature water bath shaker at 25°C, shake for 0.5 to 1 hour, stand still for 0.5 hour, and analyze the ester phase and the water phas...

Embodiment 2

[0019] Acetic acid, n-propanol and concentrated sulfuric acid are preset in the esterification kettle, and the temperature is raised for reaction. To stabilize the temperature at the top of the esterification tower at 82°C, control the reflux ratio to 4-5. Then, acetic acid, n-propanol and sulfuric acid pass through the pre-reactor continuously according to the ratio, and then enter the esterification tank for esterification. Obtain about 95% crude ester from the top of the esterification tower as the dispersed phase, use 65% potassium acetate solution extractant as the continuous phase, the solvent ratio is 1:1, the diameter of entering the tower is 50 mm, the height of the tower is 1200 mm, and the number of rotating discs It is a 30-piece liquid-liquid rotary disk extraction tower, the crude ester flow rate is controlled at 40ml / min, and the rotation speed is controlled at 300, 500, and 700r / min respectively. After extraction, the ester phase is rectified by a rectificatio...

Embodiment 3

[0022] Acetic acid, n-propanol and concentrated sulfuric acid are preset in the esterification kettle, and the temperature is raised for reaction. To stabilize the temperature at the top of the esterification tower at 82°C, control the reflux ratio to 4-5. Then, acetic acid, n-propanol and sulfuric acid pass through the pre-reactor continuously according to the ratio, and then enter the esterification tank for esterification. Obtain about 95% crude ester from the top of the esterification tower as the dispersed phase, use 65% potassium acetate solution extractant as the continuous phase, the solvent ratio is 2:1, the diameter of entering the tower is 50 mm, the height of the tower is 1200 mm, and the number of rotating discs It is a 30-piece liquid-liquid rotary disk extraction tower, the crude ester flow is controlled at 40ml / min, and the rotation speeds are 300, 500, and 700r / min respectively. After extraction, the ester phase is rectified by a rectification tower to obtain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com