Technology for separating ethylene glycol monomethyl ether and water by use of continuous azeotropic distillation method

A technology of ethylene glycol monomethyl ether and azeotropic distillation, applied in ether separation/purification, ether preparation, organic chemistry, etc., can solve the problems of high toxicity, low yield, high energy consumption, etc., and achieve low pollution and high Yield, effect of high product purity

Active Publication Date: 2013-03-06

HEBEI UNIV OF TECH

View PDF4 Cites 11 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0007] The purpose of this invention is to provide a kind of processing method of azeotropic rectification separation ethylene glycol monomethyl ether and water, it uses isopropyl acetate as entrainer, can reclaim from ethylene glycol monomethyl ether-water waste liquid The high-purity ethyle

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

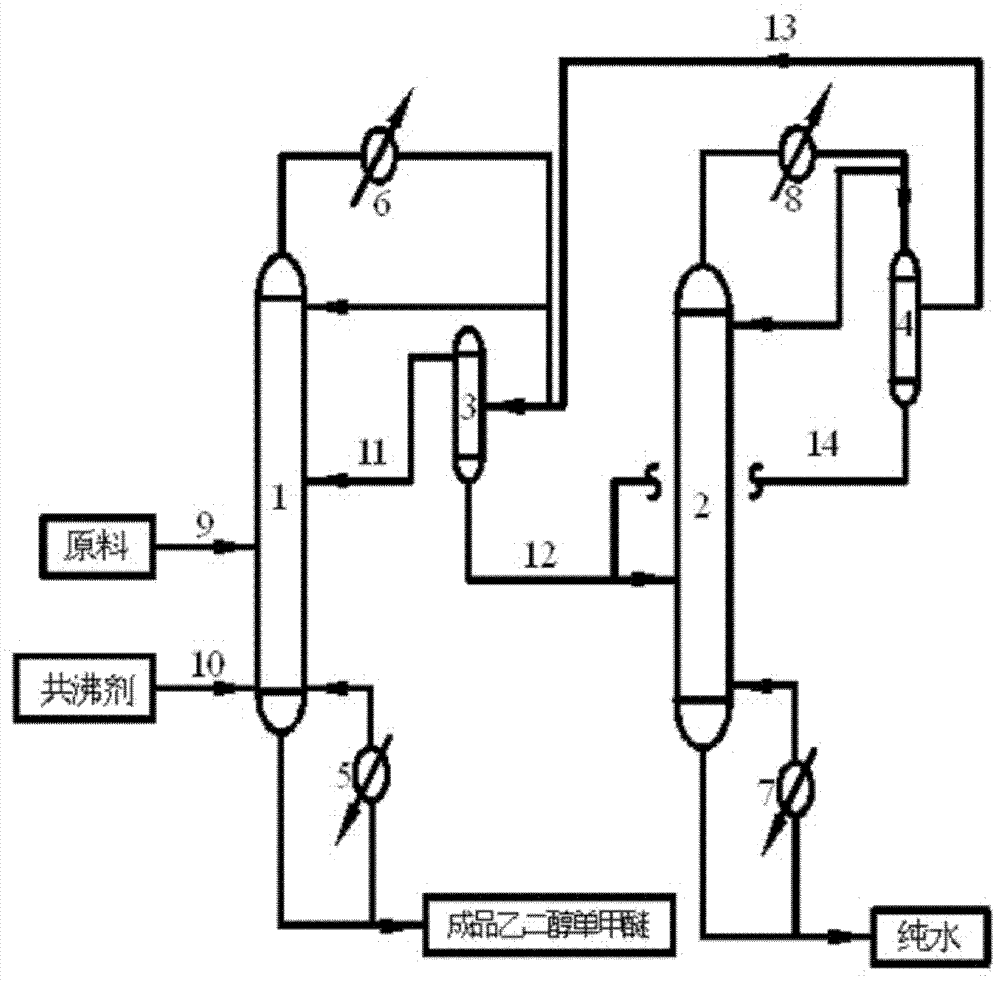

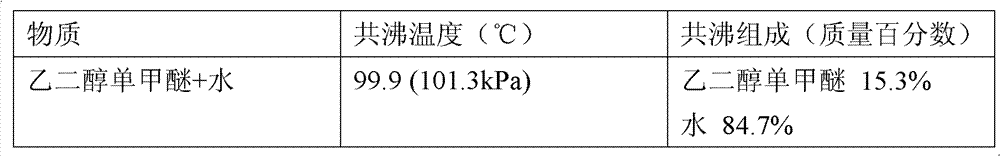

The invention discloses a technology for separating ethylene glycol monomethyl ether and water by use of a continuous azeotropic distillation method. The technology comprises the following steps of: 1) an entrainer is added into a tower kettle of an azeotropic distillation tower, the raw material enters the azeotropic distillation tower from the 28th tower plate, the operation reflux ratio is 1-3, and the reflux flows back from the tower top of the azeotropic distillation tower; and after phase splitting, the ester-rich phase enters the azeotropic distillation tower, the water-rich phase enters an entrainer recycling tower, and the product of the tower kettle of the azeotropic distillation tower is ethylene glycol monomethyl ether; and 2) after the water-rich phase enters the entrainer recycling tower, common distillation is carried out, wherein the operation reflux ratio is 1-2.5, and the reflux flows back from the tower top of the entrainer recycling tower; and after phase splitting of the produced liquid, the water-rich phase enters the entrainer recycling tower, and water is contained in the tower kettle of the entrainer recycling tower. By taking isopropyl acetate as an entrainer, the technology disclosed by the invention has the characteristics of low toxicity, low pollution, low cost, high yield, high product purity and the like, has wide application prospect, and is particularly suitable for the fields of pharmacy and the like.

Description

technical field [0001] The invention relates to a process for recovering ethylene glycol monomethyl ether in a mixed solution of ethylene glycol monomethyl ether and water in the fields of pharmacy and the like. Specifically, the entrainer isopropyl acetate is added, and all the water in the mixed solution of ethylene glycol monomethyl ether and water is taken out by continuous azeotropic distillation, thereby recovering the ethylene glycol monomethyl ether in the mixed solution. Simultaneously realize the technological method of recycling and reusing the entrainer. Background technique [0002] Ethylene glycol monomethyl ether, also known as ethylene glycol methyl ether, is a colorless transparent liquid with a boiling point of 124.6°C (101.3KPa), and is miscible with water, alcohol, ether, acetone and DMF. It is widely used as a solvent for various oils, cellulose acetate, nitrocellulose, alcohol-soluble dyes and synthetic resins. Quick-drying solvent for enamel and varn...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C07C43/13C07C41/42

Inventor 方静李春利王洪海张明禄刘婧

Owner HEBEI UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com