Continuous reaction rectification process and rectification equipment for synthesizing isopropyl alcohol

The technology of reactive distillation and reactive distillation column is applied in the field of continuous reactive distillation process for synthesizing isopropanol, which can solve the problems of high operating pressure of hydrogenation reaction, expensive catalyst, difficult regeneration, etc., and achieves reduction of material consumption and convenient equipment. Operation, good product quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

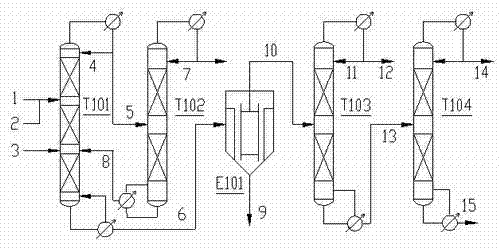

[0072] Attached figure 1 In the process flow shown, the material of the reactive distillation tower body is SUS304, and the rectification section, stripping section, and reaction section are filled with CY700 packing respectively. The number of theoretical plates in the rectification section is 12, and the number of theoretical plates in the reaction section is 25. The theoretical plate number of the stripping section is 5; the body material of the methyl ester rectifying tower is SUS304, and the tower is filled with CY700 packing, the rectifying section is 12 pieces, and the stripping section is 16 pieces. The body material of the methanol rectification tower is SUS304, and the column is filled with CY700 packing. The rectification section is 24 pieces, and the stripping section is 18 pieces; It is 25 pieces, and the stripping section is 15 pieces.

[0073] The operating conditions of the reactive distillation column are: the operating absolute pressure is 1 atm, and the iso...

Embodiment 3

[0082] Attached figure 1 In the process flow shown, the material of the reactive distillation tower body is SUS304, and the rectification section, stripping section, and reaction section are filled with CY700 packing respectively. The number of theoretical plates in the rectification section is 14, and the number of theoretical plates in the reaction section is 28. The theoretical plate number of the stripping section is 5; the body material of the methyl ester rectifying tower is SUS304, and the tower is filled with CY700 packing, the rectifying section is 14 pieces, and the stripping section is 15 pieces. The body material of the methanol rectification tower is SUS304, and the column is filled with CY700 packing. The rectification section is 22 pieces, and the stripping section is 20 pieces; It is 22 blocks, and the stripping section is 16 blocks.

[0083] The operating conditions of the reactive distillation column are: the operating absolute pressure is 1 atm, and the iso...

Embodiment 4

[0092] Attached figure 1In the process flow shown, the material of the reactive distillation tower body is SUS304, and the rectification section, stripping section, and reaction section are filled with CY700 packing respectively. The number of theoretical plates in the rectification section is 14, and the number of theoretical plates in the reaction section is 28. The theoretical plate number of the stripping section is 5; the body material of the methyl ester rectifying tower is SUS304, and the tower is filled with CY700 packing, the rectifying section is 14 pieces, and the stripping section is 15 pieces. The body material of the methanol rectification tower is SUS304, and the column is filled with CY700 packing. The rectification section is 22 pieces, and the stripping section is 20 pieces; It is 22 blocks, and the stripping section is 16 blocks.

[0093] The operating conditions of the reactive distillation column are: the operating absolute pressure is 1 atm, and the isop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com