Continuous production device and method for isopropyl acetate

A technology of isopropyl acetate and production method, applied in chemical instruments and methods, preparation of carboxylate, organic chemistry, etc., can solve the problem of unclear stratification of phase separator, long reaction time, and obtaining qualified isopropyl acetate Ester and other problems, to achieve the effect of increasing the esterification reaction time, clear layered interface, and stable ternary azeotrope

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

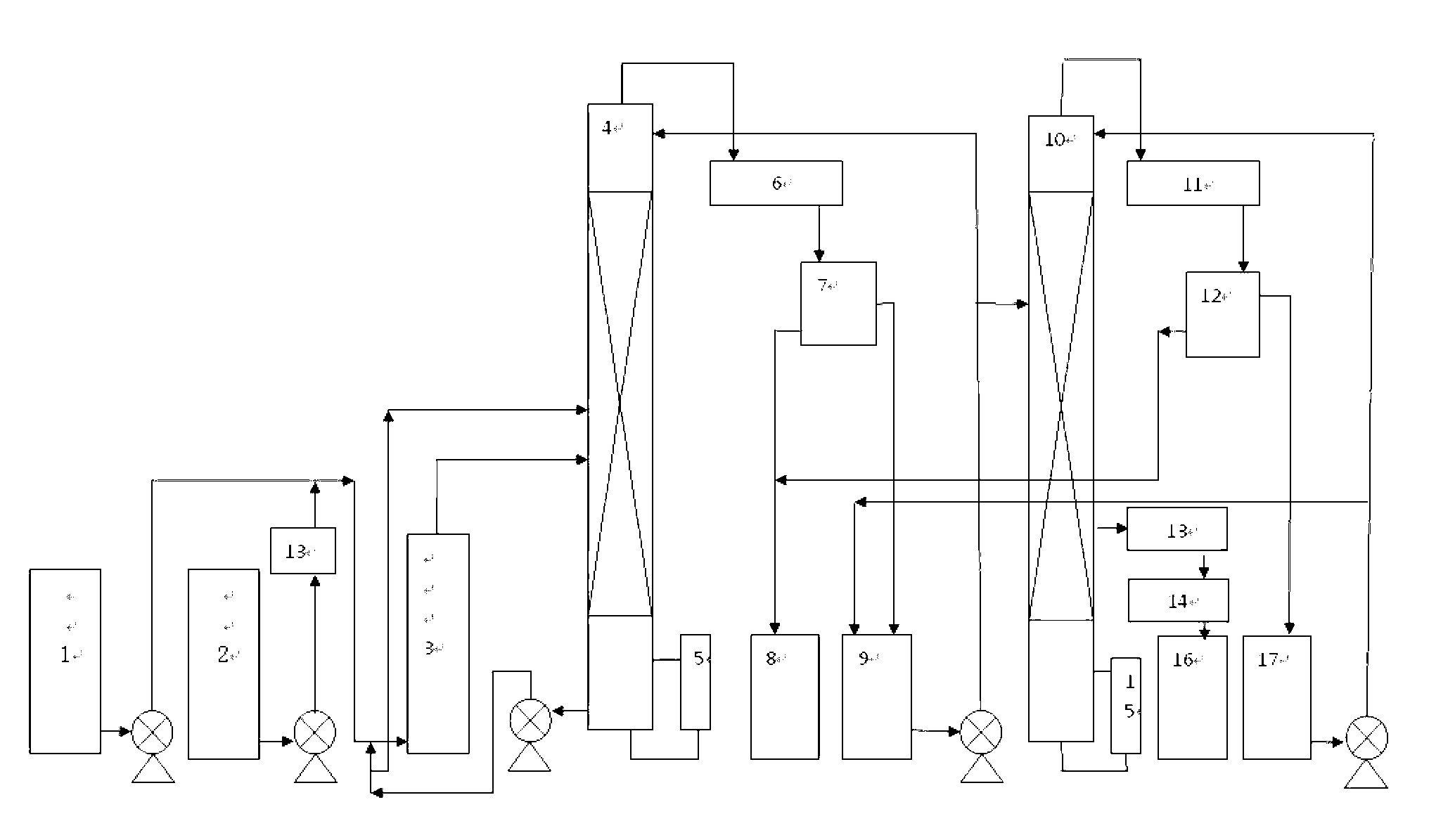

[0080] The continuous production device of the isopropyl acetate that the embodiment of the present invention provides is as figure 1 shown.

[0081] Open the metering valve at the bottom of the acetic acid storage tank 1, and continuously pump the acetic acid according to 0.55m 3 The speed of / h feeds in the reactor 3, opens the metering valve at the bottom of the isopropanol storage tank 2 at the same time, and continuously pumps the isopropanol according to 0.65m 3 The speed of / h feeds in reactor 3, and described Virahol is preheated by the heat of the first product condenser 13 condensing finished product before feeding, and throws into 30kg vitriol oil at one time in reactor 3.

[0082]The fed acetic acid and isopropanol are catalyzed by concentrated sulfuric acid to carry out esterification reaction in reactor 3 at a temperature of 80°C to 100°C. As the material continues to accumulate in the reactor 3, after it is full, it will be drawn from the discharge port at the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com