Method for preparing diester material

A diester, preparation process technology, applied in the field of preparation of diester materials, can solve problems such as leakage and increasing controversy, and achieve the effect of improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

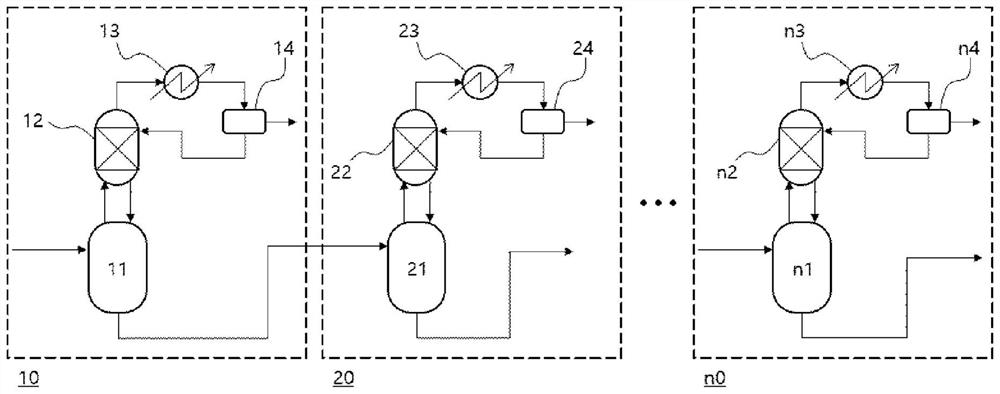

[0021] According to an exemplary embodiment of the present invention, the diester-based material may be performed through a continuous production process including a reaction section in which a total of n reaction units 10, 20 and n0 are connected in series.

[0022] Specifically, traditionally, in the preparation of diester materials, a batch preparation process is employed. However, the production of diester materials by a batch process has limitations in improving the reflux amount of steam, the productivity is very low, and there are technical limitations to improving the problem.

[0023] In addition, in order to solve the problems of the batch process having the above-mentioned problems, in the production of the diester-based material, a continuous process having a reaction part in which two or more reactors are connected in series has been developed. However, in this case, there are problems in increasing the energy usage, achieving the desired conversion and improving...

Embodiment 1 to 6 and comparative example 1 to 4

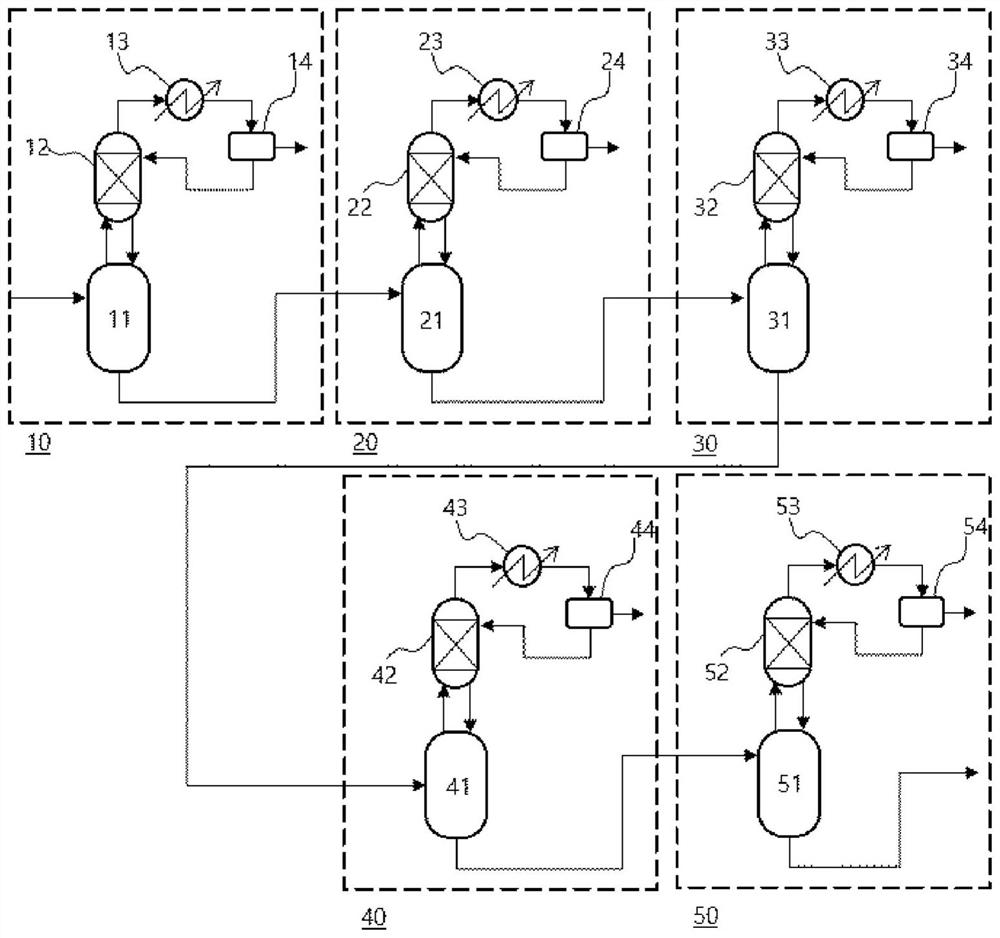

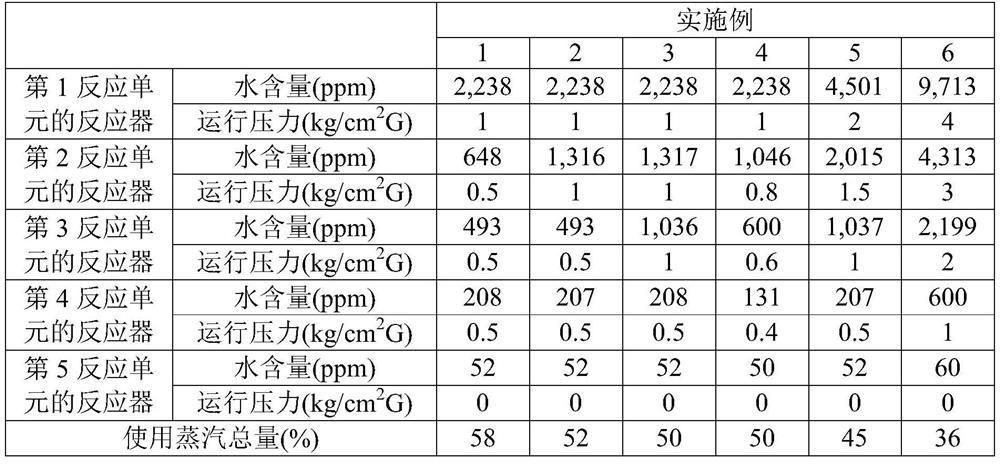

[0064] exist figure 2 In the process flow diagram shown, the production of dioctyl terephthalate (DOTP) was simulated using an ASPEN PLUS from Aspen Technology Inc. at 99% conversion.

[0065] Specifically, terephthalic acid and 2-ethylhexanol were introduced into the reactor 11 of the first reaction unit 10 while maintaining a molar ratio of 1:2 to 4.5 to perform esterification in the presence of a catalyst, and for the reactor 11 In the upper effluent stream evaporated, column 12, condenser 13 and layer separator 14 are used to reflux the alcohol to reactor 11 and remove water. Furthermore, the lower discharge stream including the reaction product in the reactor 11 is supplied to the reactor 21 of the second reaction unit 20 .

[0066] The same as the operation flow of the first reaction unit 10, the second reaction unit 20, the third reaction unit 30, the fourth reaction unit 40 and the fifth reaction unit 50 are continuously operated, and the reaction of the fifth reacti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com