Improved acetic acid purifying method

A purification method and acetic acid technology, which are applied in the purification field of low-pressure methanol oxo synthesis of acetic acid, can solve the problems of pollutant flow, heavy phase removal step pollution, high energy consumption, etc., and achieve increased reaction yield, reduced energy consumption, and less by-products Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Embodiment 1

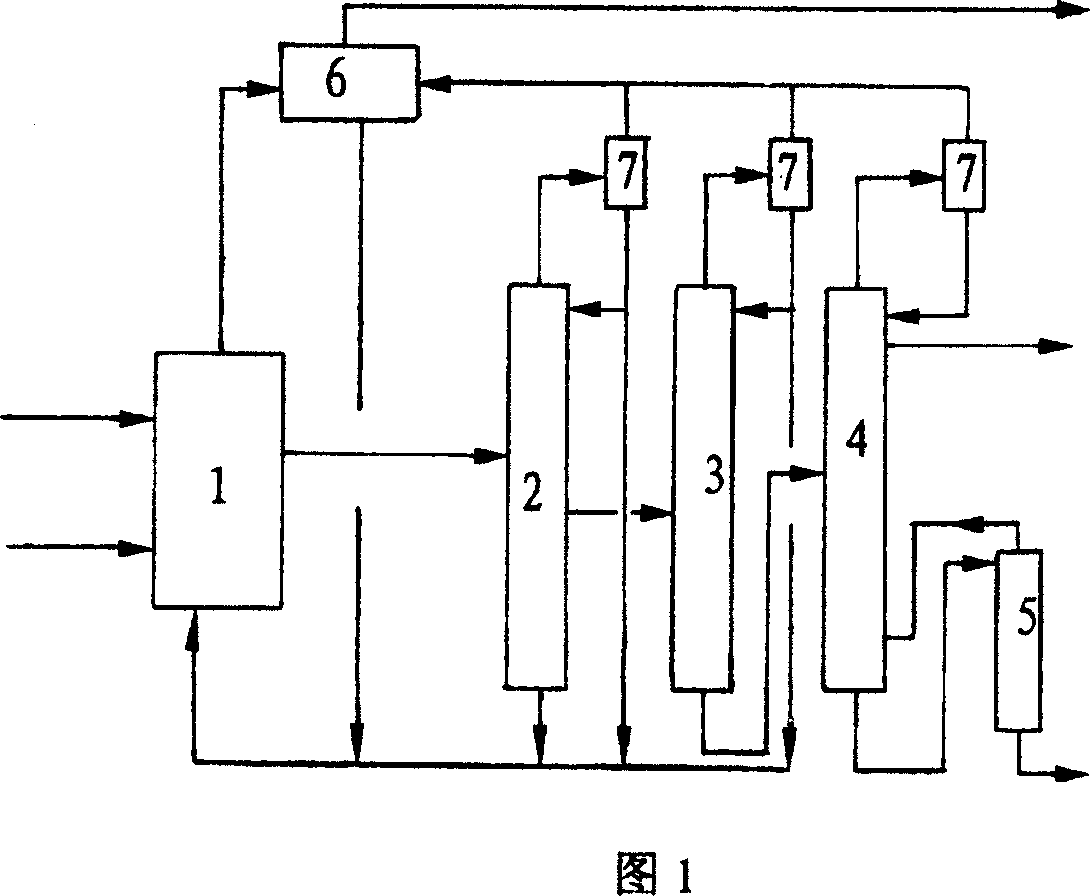

[0066] Keep the composition in Table 1 in initial acetic acid 19, carry out experiment according to the flow process described in literature ("Acetic acid and its derivatives" in "Encyclopedia of Chemical Industry" (4th edition in 1991, second volume, page 719)) Fig. 1, measure The composition of each logistics.

[0067] Implementation steps: Methanol and CO are generated in a reactor under the action of a carbonylation catalyst to generate acetic acid. The reaction liquid containing catalyst and product is flash evaporated. The tail gas generated in the reaction zone is washed in the scrubbing system 6 to recover the catalyst. The initial acetic acid 19 produced by flash evaporation passes through the light removal tower 2 shown in "Fig. 1 process" to remove light components, and then draws wet acetic acid 21 from the side line of light removal tower 2, and wet acetic acid 21 removes water and other impurities in the dehydration tower 3 . Dried acetic acid is extracted fro...

Embodiment 2

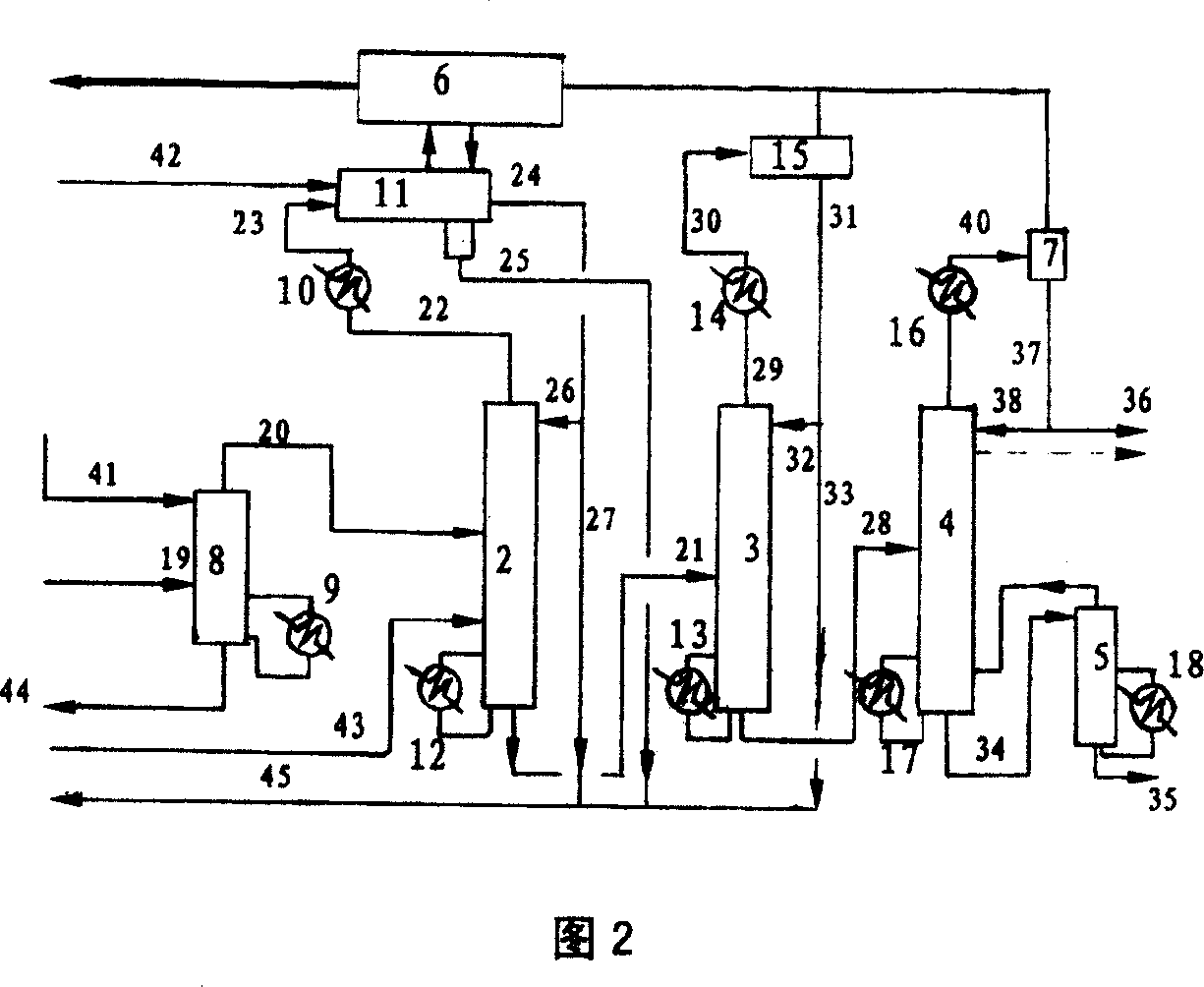

[0071] Keep the composition in table 2 at initial acetic acid 19, technological process of the present invention and implementation step are tested, and absorbing liquid is from the shunting of the wet acetic acid 21 of light removal tower 2 bottom outlets, is about 3.5% of initial acetic acid 19. The composition of each stream was determined.

[0072] Implementation steps: Methanol and CO are generated in a reactor under the action of a carbonylation catalyst to generate acetic acid. The reaction liquid containing catalyst and product is flash evaporated. The tail gas generated in the reaction zone is washed in the scrubbing system 6 to recover the catalyst. The initial acetic acid 19 that flashing produces enters the bottom of multifunctional tower 8, keeps a certain amount of absorption liquid 41 at the top of tower, has a tower bottom reboiler 9 at the bottom of tower, keeps the part liquid vaporization of heating tower kettle, by controlling Heat is used to control the ...

Embodiment 3

[0076] The initial acetic acid 19 maintains the composition in Table 3, which is a flash product with lower water content compared with Table 1. The test is carried out according to the technical process of the present invention, see flow chart 2, and the absorption liquid comes from the bottom of light removal tower 2 The split flow of the wet acetic acid 21 of the outlet is about 4%wt of the initial acetic acid 19. The composition of each stream was determined.

[0077] composition

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com