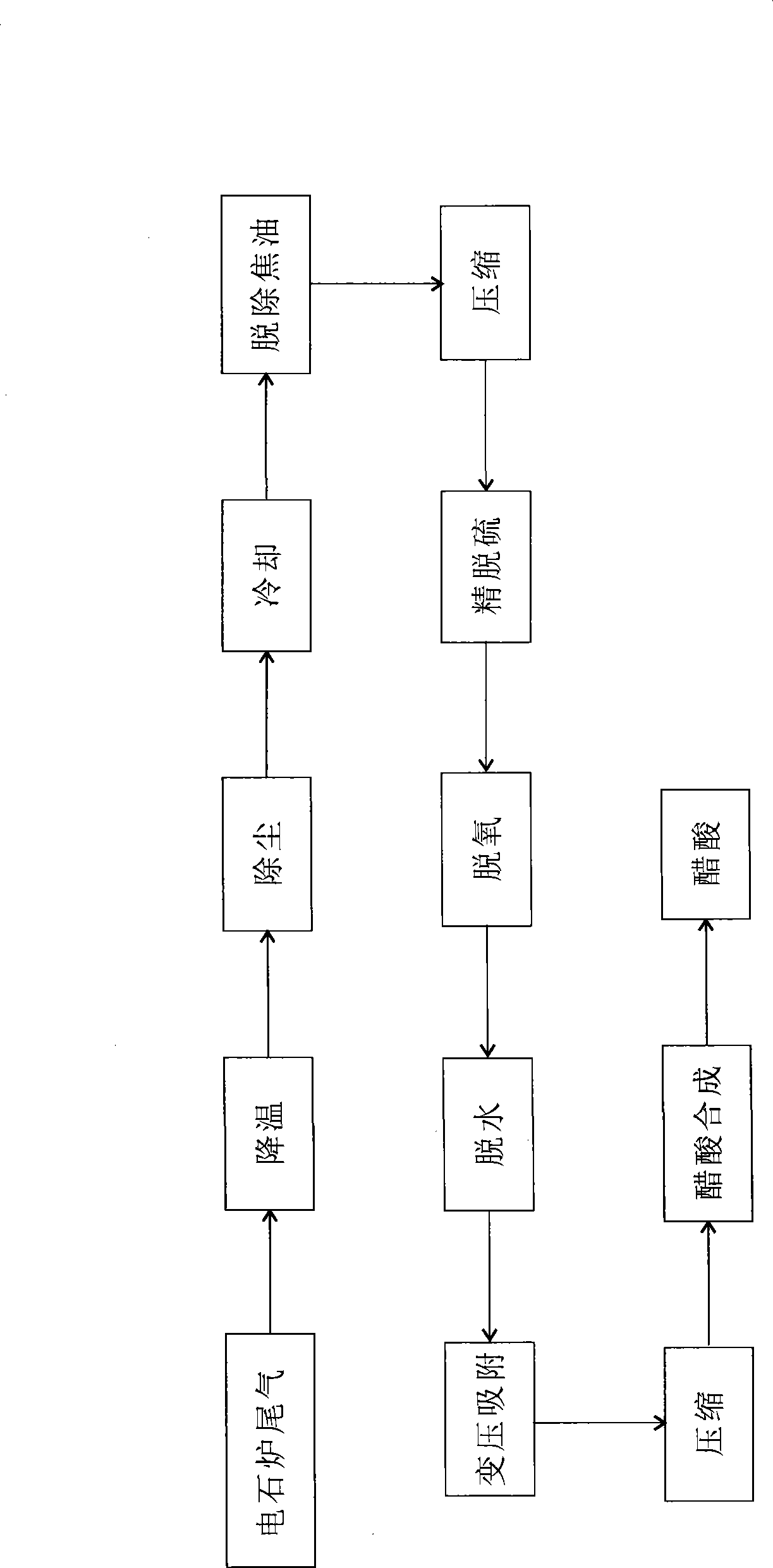

Technological process for preparing acetic acid from calcium carbide furnace tail gas

A technology of calcium carbide furnace tail gas and process method, which is applied in the chemical industry, can solve the problems of polluting the environment and wasting CO resources, and achieves the effects of reducing pollution, improving dust removal effect and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] like figure 1 Shown in, the process method of the present invention utilizing calcium carbide furnace tail gas to prepare acetic acid, it sends the high-purity CO obtained after the calcium carbide furnace tail gas is cooled, dedusted, purified and adsorbed into the acetic acid synthesis device, and reacts with methanol to generate acetic acid ; Concrete process steps are as follows:

[0016] (1) Calcium carbide furnace tail gas cooling: Send the calcium carbide furnace tail gas into the by-product steam waste heat boiler to cool down to 210-230°C, and then cool it to 160-180°C with boiler circulating water;

[0017] (2) Dust removal of calcium carbide furnace tail gas: the cooled calcium carbide furnace tail gas enters the bag filter for dust removal. The bag filter has high purification efficiency, large processing capacity, stable performance, long service life, no moving parts inside, and stable resistance , The characteristics of high gas velocity, the MC96II puls...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com