Method for recovering dilute acetic acid based on extraction/azeotropic distillation coupling process

A technology of azeotropic rectification and azeotropic rectification column is applied in the field of recovering dilute acetic acid based on the extraction/azeotropic rectification coupling process, which can solve the problems of complex process flow, increase entrainer, increase system energy consumption, etc. The effect of low energy consumption, reduced energy consumption, and reduced solvent circulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

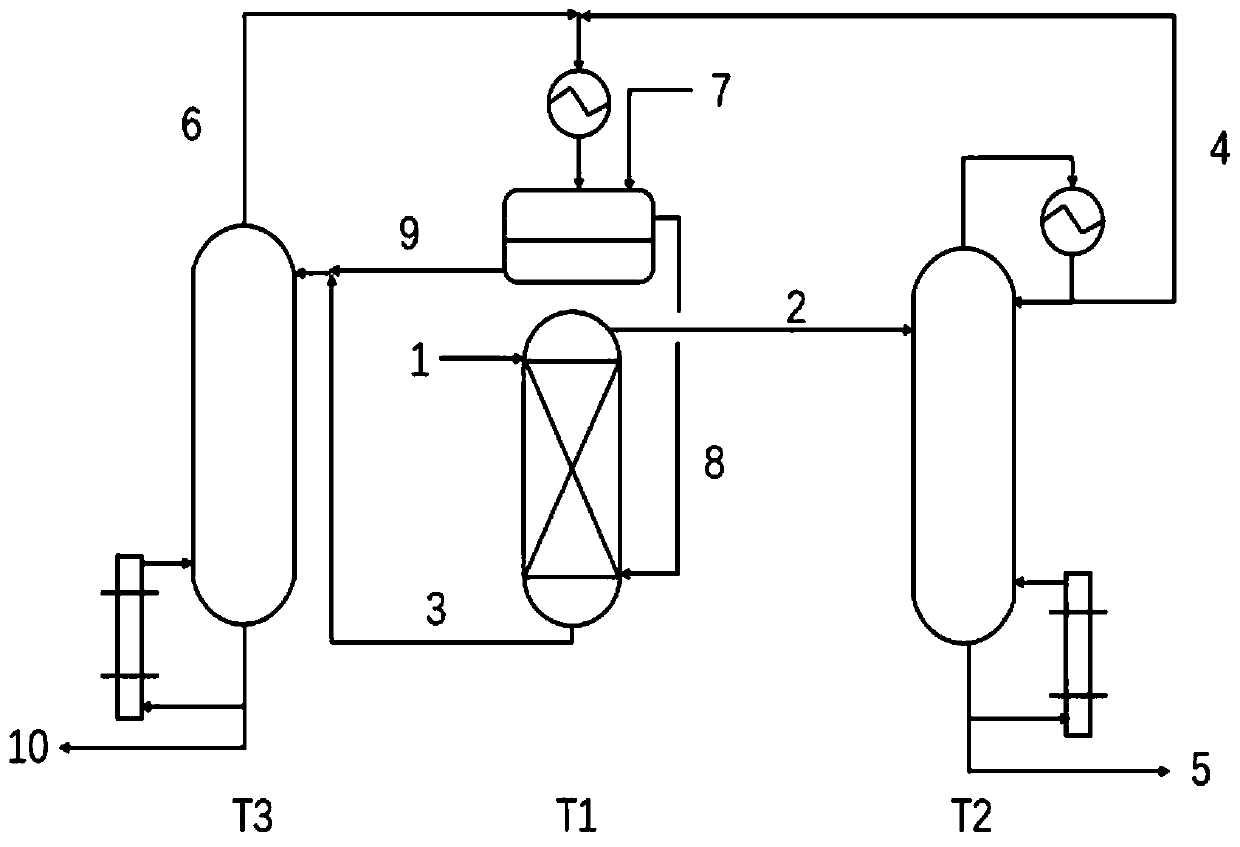

[0021] The specific flow chart of embodiment sees figure 1 . The material composition of this embodiment is based on mass fraction.

[0022] The flow rate of stream 1 is 5000 kg / h, the mass fraction of acetic acid is 30%, the mass fraction of water is 70%, the feed temperature is 40 °C, and the feed is fed from the top of the extraction tower T1. The extraction tower T1 is a packed tower with a diameter of 0.8 m, an operating temperature of 40°C, and operating under normal pressure, with a theoretical plate number of 26. The flow rate of stream 8 is 5403 kg / h, wherein the mass fraction of isopropyl acetate is 76.9%, the mass fraction of isopropanol is 19.2%, and the mass fraction of water is 3.9%. The feed position of logistics 2 is the 14th theoretical plate, the flow rate is 6724 kg / h, the mass fraction of water is 10%, the mass fraction of acetic acid is 22%, the mass fraction of isopropyl acetate is 61%, isopropanol The mass fraction is 7%. The mass flow rate of stream...

Embodiment 2

[0025] Keep the operating conditions of extraction tower T1 and solvent recovery tower T3 constant as embodiment 1, the reflux ratio of azeotropic rectification tower T2 is 1.4, other operating conditions are constant, change the content of isopropyl acetate and isopropanol in the extractant Ratio, the mass fraction of isopropyl acetate is 95%, and the mass fraction of isopropanol is 5%. The recovery rate of acetic acid after the separation of the whole process flow is 97%. The mass flow rate of acetic acid product stream 5 is 1461.26 kg / h, and the mass fraction of acetic acid is 99.8%. The mass flow rate of waste water stream 10 is 3539 kg / h, and the mass fraction of water is 99%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com