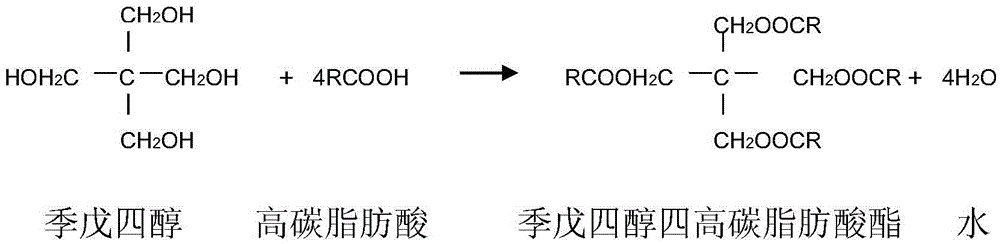

Method for preparing high-quality pentaerythritol high-carbon fatty acid ester by extraction process

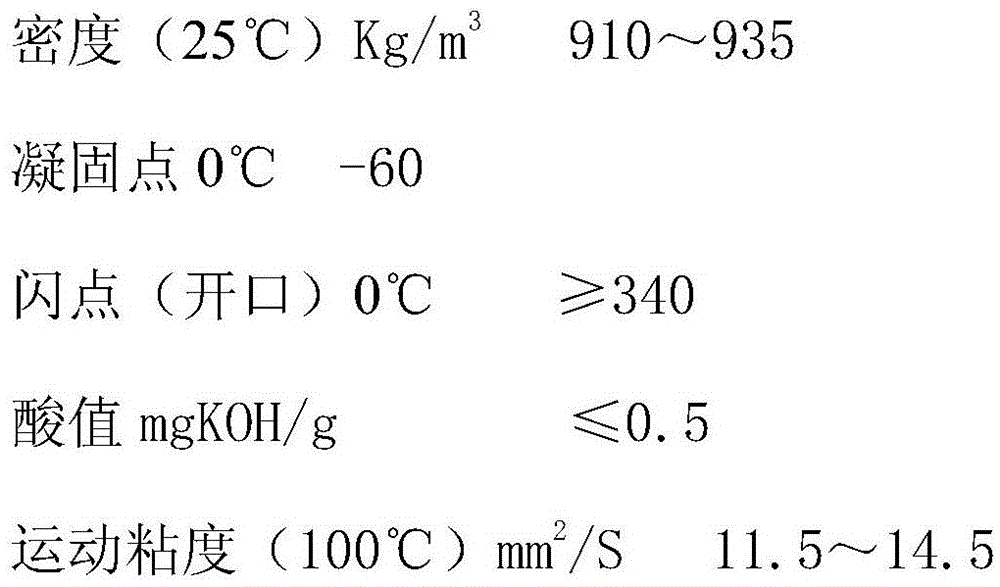

A high-carbon fatty acid and pentaerythritol technology, which is applied in the direction of fatty acid esterification, fatty acid production, fatty acid chemical modification, etc., can solve the problems of difficulty in stratification between fatty acid sodium soap and ester, impossibility of production operation, high product viscosity, etc., and achieve flash High point, small investment in equipment, good heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

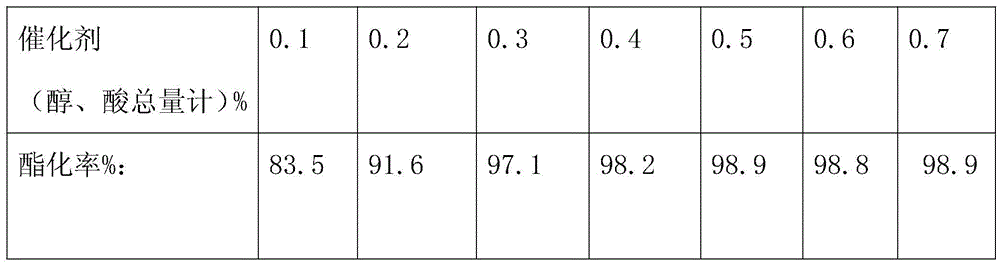

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1: prepare the method for high-quality pentaerythritol high-carbon fatty acid ester with extraction process, the steps are as follows:

[0029] 1. Material selection: select high-carbon fatty acids with an acid value of 190-200 and an iodine value of 80-100, a purity of ≥98% pentaerythritol, and a purity of ≥99.5% of 200-mesh zinc powder; the proportioning composition of the above-mentioned raw materials is:

[0030] 100kg high carbon fatty acid

[0031] Pentaerythritol 12 kg

[0032] Zinc powder 0.5 kg;

[0033] ②Esterification: process conditions: the temperature of esterification reaction is controlled at 180-200°C,

[0034] Vacuum degree: ≤1000pa, reaction time 6 hours;

[0035] In a vacuum state, the water generated by esterification is vaporized and pumped out of the reactor. When the temperature of the esterification reaction rises to 210 ° C, the vacuum degree is ≤ 500 Pa, and the esterification reaction ends when no water vapor is drawn out;

[0...

Embodiment 2

[0039] Embodiment 2: prepare the method for high-quality pentaerythritol high-carbon fatty acid ester with extraction process, the steps are as follows:

[0040] 1. Material selection: select high-carbon fatty acids with an acid value of 190-200 and an iodine value of 80-100, a purity of ≥98% pentaerythritol, and a purity of ≥99.5% of 200-mesh zinc powder; the proportioning composition of the above-mentioned raw materials is:

[0041] 110kg high carbon fatty acid

[0042] Pentaerythritol 12 kg

[0043] Zinc powder 0.6 kg;

[0044] ②, Esterification: process conditions: the temperature of the esterification reaction is controlled at 210°C,

[0045] Vacuum degree: ≤1000pa, reaction time 7 hours;

[0046] In a vacuum state, the water generated by esterification is vaporized and pumped out of the reactor. When the temperature of the esterification reaction rises to 210 ° C, the vacuum degree is ≤ 500 Pa, and the esterification reaction ends when no water vapor is drawn out;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com