Reaction-extraction coupling method for preparation of hydroxylamine salt / hydroxylamine

A hydroxylamine salt and extraction technology, applied in the direction of hydroxylamine, nitrogen and non-metallic compounds, etc., can solve the problems of little significance and not solve the problem of hydroxylamine salt from the source, and achieve the effect of stable quality, low energy consumption and high selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

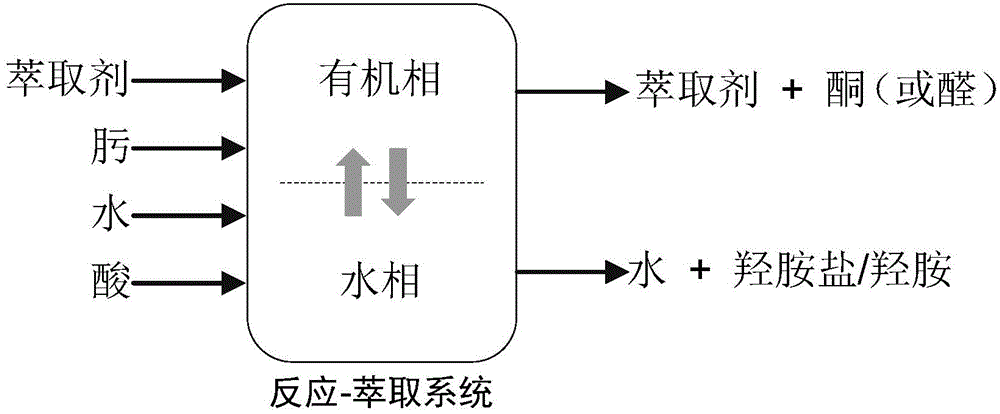

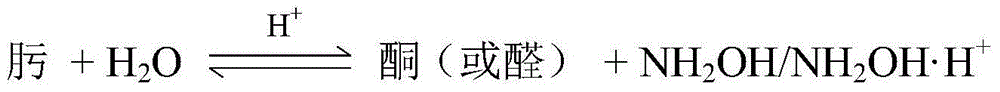

Method used

Image

Examples

Embodiment 1

[0077] Example 1: Press H + The molar ratio to cyclohexanone oxime is 2:1, measure 50ml of 2mol / L sulfuric acid, weigh 11.5g of cyclohexanone oxime with a purity of 99.0%, mix it and add it to a 250ml three-necked flask equipped with a condensing device , and then added 50ml of cyclohexane, heated and stirred at 25°C for 1h. After the reaction, stand for stratification, cyclohexanone oxime and cyclohexanone are dissolved in the upper oil phase, and the lower layer is the water phase, mainly hydroxylamine sulfate; the oil phase is quantitatively analyzed by gas chromatography internal standard method, and the water phase is analyzed by oxidation-reduction titration The content of hydroxylamine salt was analyzed; the conversion rate of cyclohexanone oxime was 32.7%, and the selectivity of hydroxylamine sulfate was 99.2%.

Embodiment 2

[0078] Embodiment 2: reaction step is as embodiment 1, and difference is that the ketoxime in the reaction is 8.7g purity and is the butanone oxime of 99.5%; The conversion rate of butanone oxime is 39.8%, and the selectivity of hydroxylamine sulfate is 99.4%.

Embodiment 3

[0079] Embodiment 3: The reaction steps are as in Example 1, the difference is that the ketoxime in the reaction is 7.3g of acetone oxime with a purity of 99.7%; the conversion rate of acetoxime is 42.5%, and the selectivity of hydroxylamine sulfate is 99.6% .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com