Separation of N,N-dimethylacetamide-acetic acid mixed system

A technology of dimethylacetamide and acetic acid, which is applied in the separation/purification of carboxylic acid compounds, separation/purification of carboxylic acid amides, organic chemistry, etc., can solve the problem of waste of acetic acid resources, and achieve high operating flexibility and simple process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

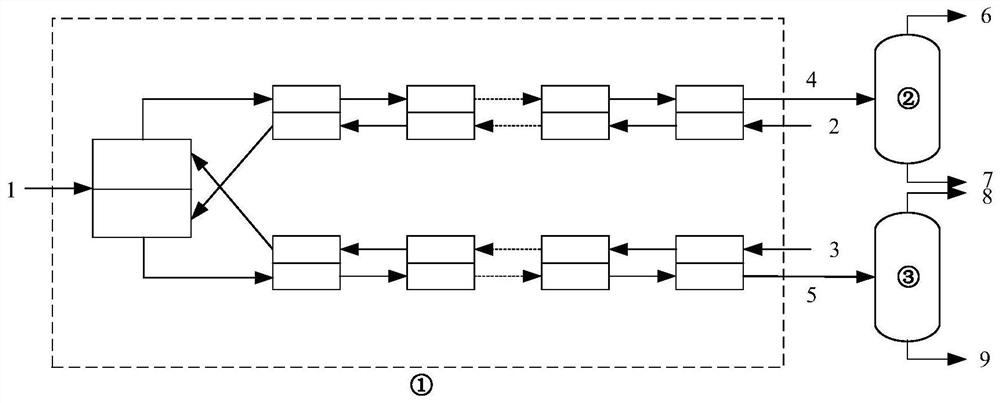

Embodiment 1

[0036] There is a mixture of N,N-dimethylacetamide and acetic acid, the mass ratio is 50:50, chloroform is used as the hydrophobic phase, and water is used as the hydrophilic phase. Two-phase multi-stage countercurrent extraction is carried out. The total number of extraction stages is 12. , where the mixture enters from the 6th stage position counting from the hydrophobic phase feed port. The mass flow rate of the treated mixture is 0.2 times the mass flow rate of the total extractant (including the hydrophobic phase and the hydrophilic phase), wherein the mass ratio of the hydrophobic phase to the hydrophilic phase is 1. The extraction was carried out at 25° C. to obtain an extract phase and a raffinate phase, respectively. The raffinate phase enters the raffinate phase rectification tower, the operating pressure is 0.5atm, the reflux ratio is 0.5, the temperature of the tower bottom is controlled at 96°C, and finally the acetic acid product is obtained in the tower bottom. ...

Embodiment 2

[0038] There is a batch of mixture of N,N-dimethylacetamide and acetic acid, the mass ratio is 30:70, with eugenol as the hydrophobic phase and water as the hydrophilic phase, a two-phase multi-stage countercurrent extraction is carried out, and the total number of extraction stages is 12 stage, where the mixture enters from the 4th stage position counted from the hydrophobic phase feed port. The mass flow rate of the treated mixture is 0.2 times the mass flow rate of the total extractant (including the hydrophobic phase and the hydrophilic phase), wherein the mass ratio of the hydrophobic phase to the hydrophilic phase is 0.5. The extraction was carried out at 25° C. to obtain an extract phase and a raffinate phase, respectively. The raffinate phase enters the raffinate phase rectification tower, the operating pressure is 0.5atm, the reflux ratio is 1, the temperature of the tower bottom is controlled at 96°C, and finally the acetic acid product is obtained in the tower botto...

Embodiment 3

[0040] There is a mixture of N,N-dimethylacetamide and acetic acid, the mass ratio is 20:80, with aniline as the hydrophobic phase and water as the hydrophilic phase, a two-phase multi-stage countercurrent extraction is performed, and the total number of extraction stages is 12 , where the mixture enters from the third stage position counting from the hydrophobic phase feed port. The mass flow rate of the treated mixture is 0.2 times the mass flow rate of the total extractant (including the hydrophobic phase and the hydrophilic phase), wherein the mass ratio of the hydrophobic phase to the hydrophilic phase is 0.2. The extraction was carried out at 25° C. to obtain an extract phase and a raffinate phase, respectively. The raffinate phase enters the raffinate phase rectification tower, the operating pressure is 0.5atm, the reflux ratio is 2, the temperature of the tower bottom is controlled at 96°C, and finally the acetic acid product is obtained in the tower bottom. 92.4%. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com