Method for de-iodinating and refining acetic acid

A refining method, acetic acid technology, applied in the separation/purification of carboxylic acid compounds, ion exchange, organic chemistry, etc., can solve the problem of low iodide ion removal content, acetic acid products cannot use vinyl acetate, and superior products cannot meet the quality of high-end users demand and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

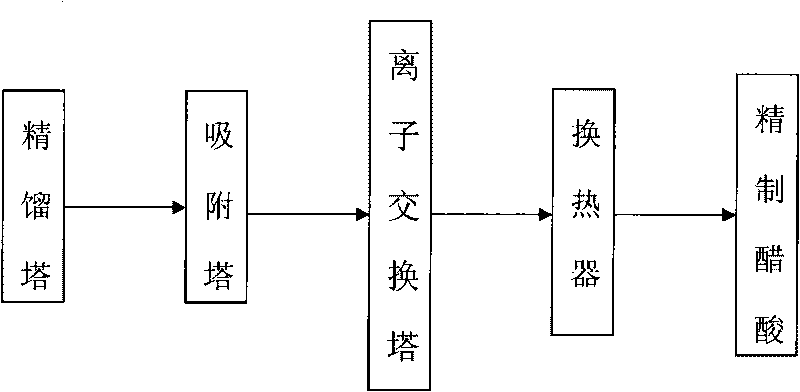

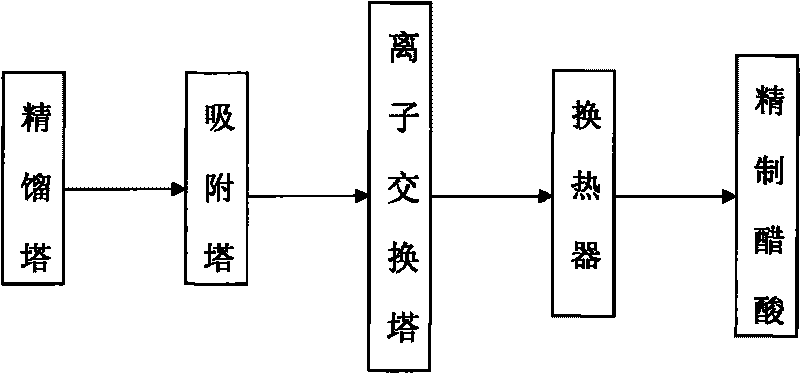

Image

Examples

Embodiment 1

[0017] After the acetic acid extracted from the rectification tower is cooled to 100°C, it enters the adsorption tower. The pressure in the adsorption tower is 0.2Mpa and the temperature is 40°C. Acetic acid enters the ion exchange tower, the pressure of the ion exchange tower is 0.2Mpa, and the temperature is 80°C. After the adsorption of polystyrene ion exchange resin, the iodine in the acetic acid is removed to obtain refined acetic acid. The acetic acid coming out of the ion exchange tower After cooling through a heat exchanger, the temperature drops to 50°C, and then enters a storage tank for storage.

Embodiment 2

[0019] After the acetic acid extracted from the rectification tower is cooled to 100°C, it enters the adsorption tower. The pressure in the adsorption tower is 0.5Mpa and the temperature is 138°C. Acetic acid enters the ion exchange tower, the pressure of the ion exchange tower is 0.5Mpa, and the temperature is 100°C. After the adsorption of polystyrene ion exchange resin, the iodine in the acetic acid is removed to obtain refined acetic acid. The acetic acid coming out of the ion exchange tower After cooling through a heat exchanger, the temperature drops to 30°C, and then enters a storage tank for storage.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com