Method for synthesizing acetic acid through carbonylation of low-pressure methanol

A technology of chemical synthesis and methanol, which is applied in the field of acetic acid synthesis, can solve the problems of high production cost of acetic acid, high steam effect, unfavorable market competition, etc., and achieve the effect of saving steam consumption, saving energy consumption, and reducing invalid cycles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

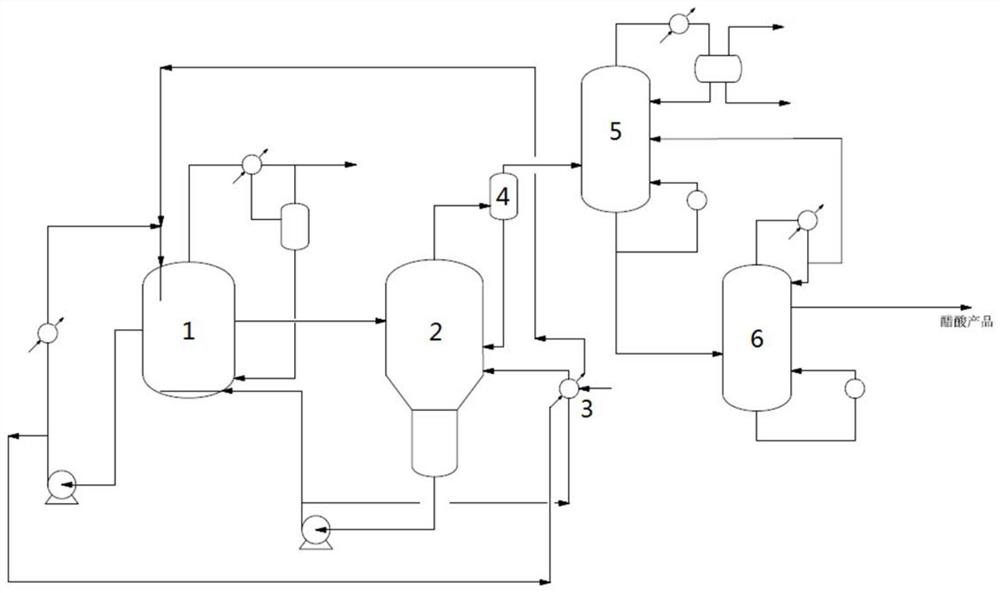

[0051] A method for the synthesis of acetic acid by carbonylation of methanol at low pressure, its technological process is as follows figure 1 shown, including the following steps:

[0052] (1) In the presence of a catalyst, feed methanol and CO into the non-stirred reactor 1 for carbonylation reaction. The non-stirred reactor 1 used adopts a self-operated circulation mixing system, and the methanol and liquid phase components are separated in the non-stirred reactor. After being mixed externally to form an external mixed liquid, it enters the reactor. After mixing, the temperature of the liquid phase components is lowered, and the temperature of the methanol feed is also raised, which achieves the purpose of preheating the feed in advance; The mixed liquid enters the non-stirred reactor at different angles, and the mixed liquid is stirred after entering the reactor to achieve the effect of the agitator, so that mechanical stirring or other stirring methods are not required, ...

Embodiment 2

[0058] A method for the synthesis of acetic acid by carbonylation of methanol at low pressure, its technological process is as follows figure 1 shown, including the following steps:

[0059] (1) In the presence of a catalyst, feed methanol and CO into the non-stirred reactor 1 for carbonylation reaction. The non-stirred reactor 1 used adopts a self-operated circulation mixing system, and the methanol and liquid phase components are separated in the non-stirred reactor. After being mixed externally to form an external mixed liquid, it enters the reactor. After mixing, the temperature of the liquid phase components is lowered, and the temperature of the methanol feed is also raised, which achieves the purpose of preheating the feed in advance; The mixed liquid enters the non-stirred reactor at different angles, and the mixed liquid is stirred after entering the reactor to achieve the effect of the agitator, so that mechanical stirring or other stirring methods are not required, ...

Embodiment 3

[0065] A method for the synthesis of acetic acid by carbonylation of methanol at low pressure, its technological process is as follows figure 1 shown, including the following steps:

[0066] (1) In the presence of a catalyst, feed methanol and CO into the non-stirred reactor 1 for carbonylation reaction. The non-stirred reactor 1 used adopts a self-operated circulation mixing system, and the methanol and liquid phase components are separated in the non-stirred reactor. After being mixed externally to form an external mixed liquid, it enters the reactor. After mixing, the temperature of the liquid phase components is lowered, and the temperature of the methanol feed is also raised, which achieves the purpose of preheating the feed in advance; The mixed liquid enters the non-stirred reactor at different angles, and the mixed liquid is stirred after entering the reactor to achieve the effect of the agitator, so that mechanical stirring or other stirring methods are not required, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com