Process for crylic acid azeotropism refining and recovering acetic acid

A technology of acrylic acid and ethyl propionate, applied in the separation/purification of carboxylic acid compounds, organic chemistry, etc., can solve the problems of unreasonable economy and high separation cost, and achieve the effects of saving steam, significant economic benefits, and reducing operating load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

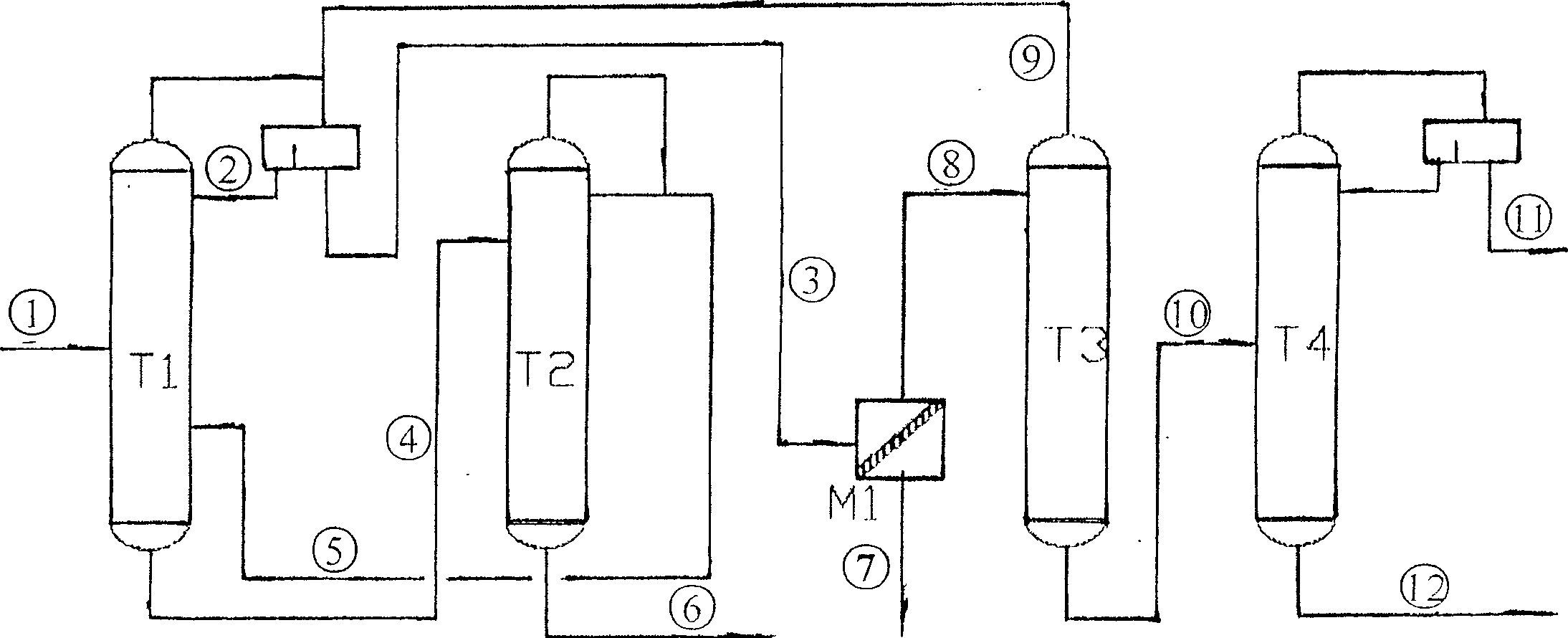

Method used

Image

Examples

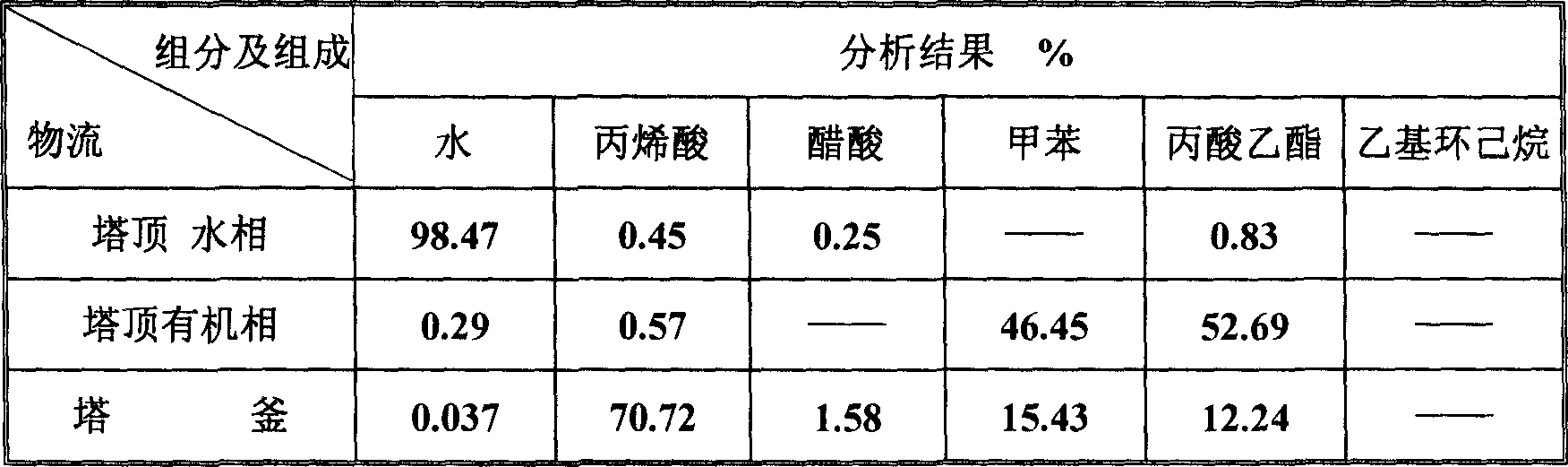

example 1

[0030] The dehydration test was carried out with ethyl propionate / toluene (1:1) as the entrainer, and the ratio of the recirculation flow rate of the entrainer to the amount of the feed material was 3.2:1. The experimental operating pressure is 15kPaA, the temperature at the top of the tower is 49°C, and the temperature at the bottom of the tower is 82°C. The analysis results of the materials at the top of the tower and at the bottom of the tower are as follows:

[0031]

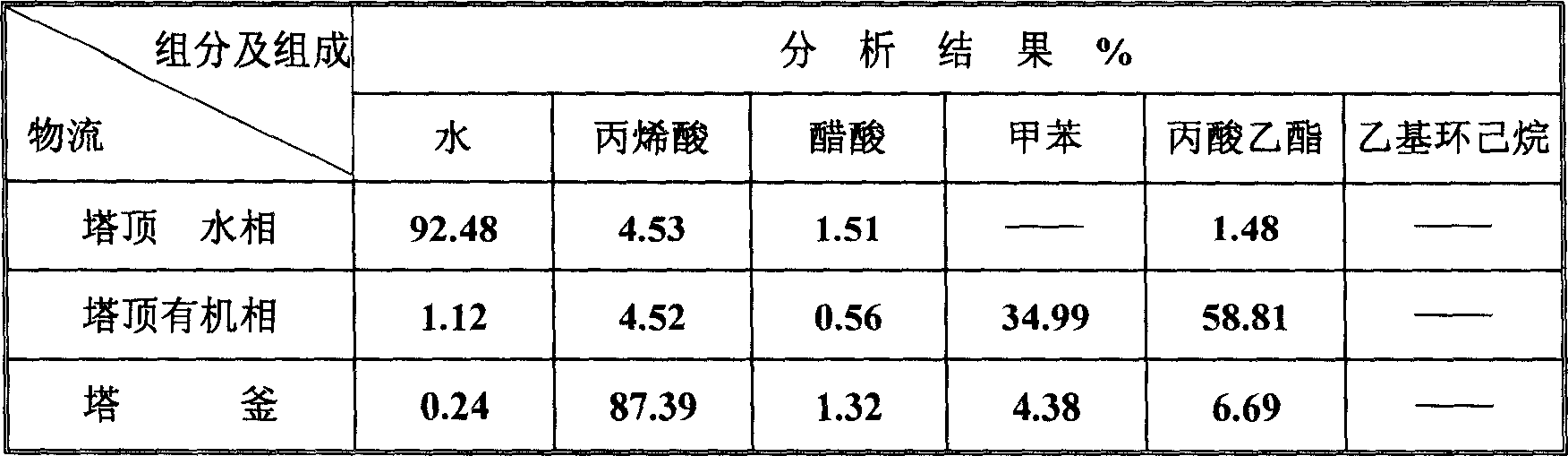

example 2

[0033] The dehydration test was carried out with ethyl propionate / toluene (2:1) as the entrainer, and the ratio of the recirculation flow rate of the entrainer to the amount of the feed material was 3.8:1. The experimental operating pressure is 15kPaA, the temperature at the top of the tower is 47°C, and the temperature at the bottom of the tower is 87°C. The analysis results of the materials at the top of the tower and at the bottom of the tower are as follows:

[0034]

example 3

[0036] The dehydration test was carried out with ethyl propionate / toluene (1:2) as the entrainer, and the ratio of the recirculation flow rate of the entrainer to the amount of the feed material was 3.4:1. The experimental operating pressure is 15kPaA, the temperature at the top of the tower is 51°C, and the temperature at the bottom of the tower is 82°C. The analysis results of the materials at the top of the tower and at the bottom of the tower are as follows:

[0037]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com