Process for producing acetic acid by utilizing tail gas of calcium carbide furnace

A technology of calcium carbide furnace tail gas and acetic acid, which is applied in the chemical industry, can solve the problems of waste of CO resources, pollute the environment, etc., and achieve the effects of reducing production costs, improving economic benefits, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

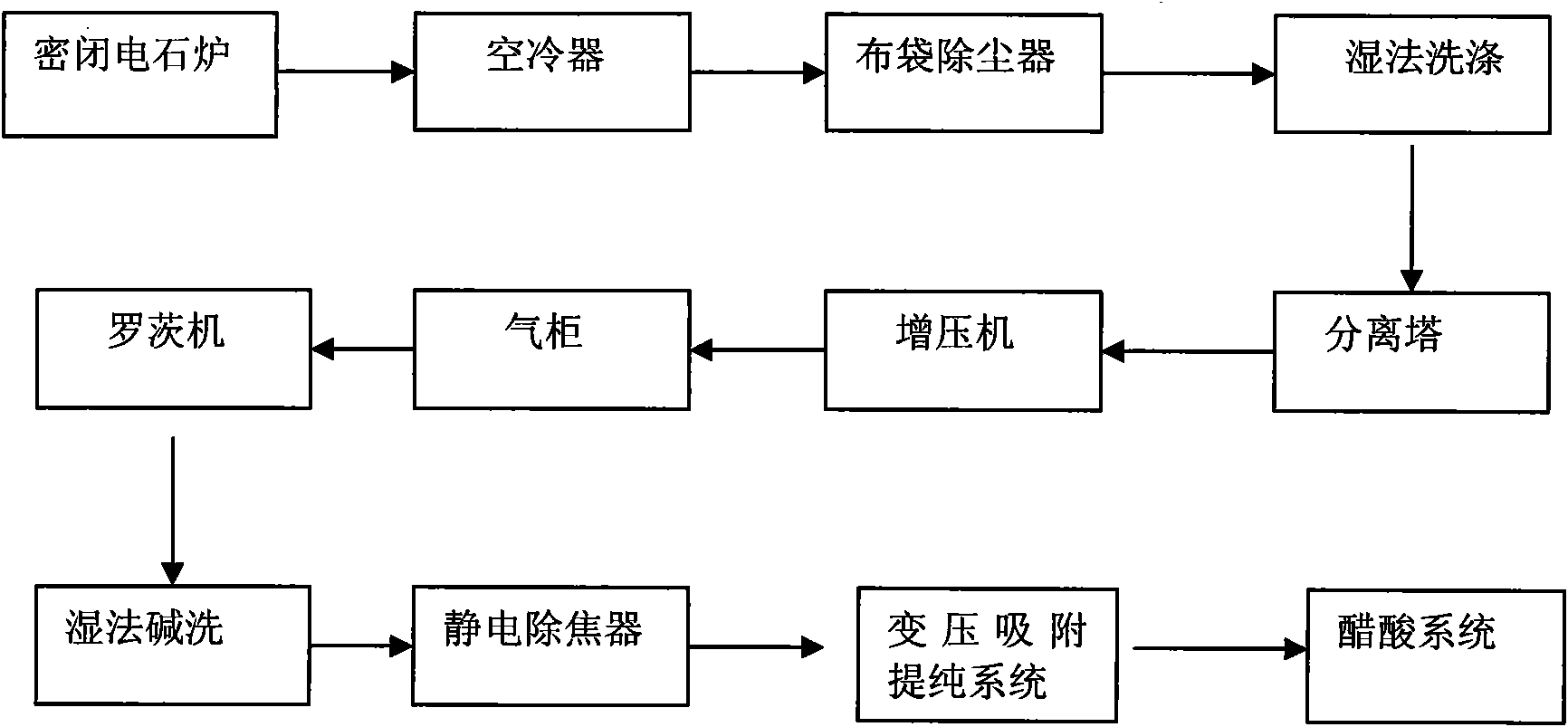

[0029] Concrete technological process of the present invention is:

[0030] The high-temperature calcium carbide furnace tail gas of about 600 ℃ drawn from the exhaust pipe of the closed calcium carbide furnace is cooled to 220 ℃ ~ 250 ℃ by the air-cooled dust collector, and then sent to the bag filter for dust removal. After leaving the bag filter, the calcium carbide furnace tail gas contains dust. The amount is 40mg / Nm 3 the following. Then send it to the cooling and dedusting water washing tower for further wet cooling and dedusting, so that the temperature of the calcium carbide furnace tail gas is less than 45°C and the dust content is less than 1mg / Nm 3 the following. After leaving the water washing tower, the water droplets entrained in the gas are separated by the separation tower, and a booster is introduced to increase the pressure of the gas to 350 mm Hg, and then it is stored in a pipeline gas supply cabinet. The purified calcium carbide furnace tail gas from t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com