Method for purifying acetic acid from acetic acid wastewater

A technology for acetic acid and wastewater, applied in the separation/purification of carboxylic acid compounds, organic chemistry, etc., can solve the problems of large investment in equipment, generation of secondary wastewater, environmental pollution, etc., to reduce energy costs, equipment investment, and environmental protection friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

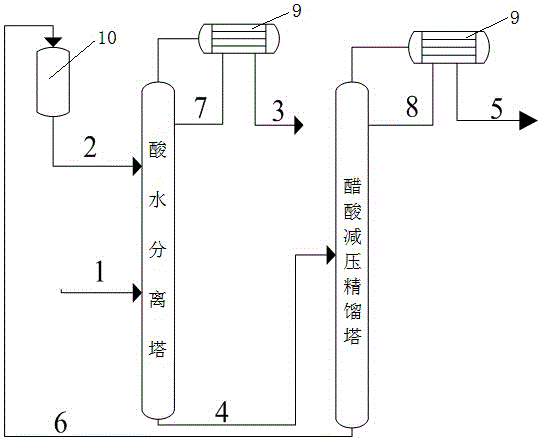

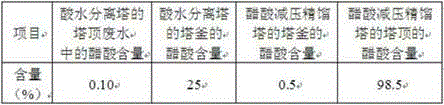

[0030] Such as figure 1 Shown, the present invention purifies the method for acetic acid from acetic acid waste water, comprises the following steps:

[0031] (1) The acetic acid wastewater containing 45% acetic acid enters the tower through the first line 1 from the middle and lower part of the acid-water separation tower. The upper middle part of the acid-water separation tower enters the tower, and the acetic acid wastewater and dimethylformamide undergo extraction and rectification reactions in the acid-water separation tower;

[0032] (2) After being cooled by the condenser 9, the gas phase flow at the top of the acid-water separation tower is returned to the acid-water separation tower through the seventh line 7, and the waste water stream is extracted through the third line 3; the liquid phase obtained by the acid-water separation tower The stream enters the tower from the middle part of the acetic acid vacuum rectification tower through the fourth line 4 and rectifies...

Embodiment 2

[0037] Such as figure 1 Shown, the present invention purifies the method for acetic acid from acetic acid waste water, comprises the following steps:

[0038] (1) The acetic acid waste water containing 54% acetic acid enters the tower from the middle and lower part of the acid-water separation tower through the first line 1, and at the same time, the extraction agent sulfolane passes through the second line 2 from the acid-water separation tower from the high-position transfer tank 10 The upper part of the middle part enters the tower, and the acetic acid waste water and sulfolane carry out the reaction of extraction and rectification in the acid-water separation tower;

[0039] (2) After being cooled by the condenser 9, the gas phase flow at the top of the acid-water separation tower is returned to the acid-water separation tower through the seventh line 7, and the waste water stream is extracted through the third line 3; the liquid phase obtained by the acid-water separation...

Embodiment 3

[0044] Such as figure 1 Shown, the present invention purifies the method for acetic acid from acetic acid waste water, comprises the following steps:

[0045](1) Enter the acetic acid waste water containing 50% acetic acid into the tower through the first line 1 from the middle and lower part of the acid-water separation tower. At the same time, the mixture of the extractant N-methylacetamide and N-formylmorpholine is The high-level transfer tank 10 enters the tower from the upper middle part of the acid-water separation tower through the second line 2, and the acetic acid waste water and the extractant carry out the reaction of extractive distillation in the acid-water separation tower;

[0046] (2) After being cooled by the condenser 9, the gas phase flow at the top of the acid-water separation tower is returned to the acid-water separation tower through the seventh line 7, and the waste water stream is extracted through the third line 3; the liquid phase obtained by the aci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com