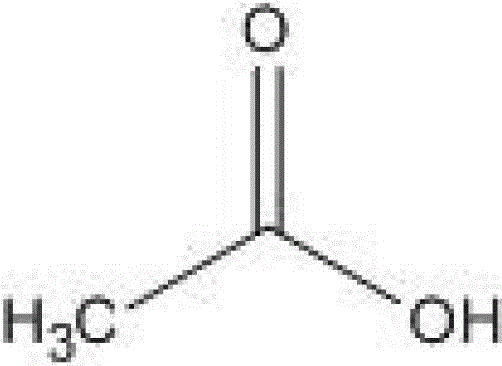

Purification method for glacial acetic acid

A purification method, the technology of glacial acetic acid, applied in the separation/purification of carboxylic acid compounds, chemical instruments and methods, organic chemistry, etc., can solve the problems of long time and low purity, and achieve stable quality, high purity, and high yield Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Preparation of tetraacetylborax: heat boric acid and acetic anhydride with a mass ratio of 1:5 to 60°C, then cool and filter to prepare tetraacetylborax.

[0020] Add 1000g of industrial glacial acetic acid into a 2000ml three-neck flask equipped with a rectification device, a thermometer and a heating device, add 40g of acetic anhydride and 20g of potassium permanganate in sequence, heat and reflux for 2 hours to remove organic impurities in the glacial acetic acid, and then add 30g of tetraacetylborax was heated under reflux for 0.5h, dried, and then 40g of 4A molecular sieve was added for adsorption and purification for 20min. Finally, 909g of purified glacial acetic acid was obtained by rectification at a flow rate of 20mL / min, with a yield of 90.9% and a purity of 99.82%.

Embodiment 2

[0022] Preparation of tetraacetylborax: heat boric acid and acetic anhydride with a mass ratio of 1:4 to 50°C, then cool and filter to prepare tetraacetylborax.

[0023] Add 1000g of industrial product glacial acetic acid into a 2000ml three-neck flask equipped with a rectifying device, a thermometer and a heating device, add 50g of acetic anhydride and 35g of potassium permanganate in turn, heat and reflux for 2.5h to remove organic impurities in the glacial acetic acid, and then Add 40g of tetraacetylborax, heat and reflux for 0.75h, dry, then add 50g of 4A molecular sieve for adsorption and purification for 25min, and finally carry out rectification and collection at a flow rate of 15mL / min to obtain 916g of purified glacial acetic acid, with a yield of 91.6% and a purity of 99.87%. .

Embodiment 3

[0025] Preparation of tetraacetylborax: Heat boric acid and acetic anhydride with a mass ratio of 1:6 to 70°C, then cool and filter to prepare tetraacetylborax.

[0026] Add 1000g of industrial glacial acetic acid into a 2000ml three-necked flask equipped with a rectifying device, a thermometer and a heating device, add 60g of acetic anhydride and 50g of potassium permanganate in sequence, heat and reflux for 3 hours to remove organic impurities in the glacial acetic acid, and then add 50g of tetraacetylborax was heated and refluxed for 1 hour, dried, then added with 60g of 4A molecular sieves for adsorption and purification for 30 minutes, and finally collected by rectification at a flow rate of 10mL / min to obtain 929g of purified glacial acetic acid with a yield of 92.9% and a purity of 99.95%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com