A kind of dilute acetic acid recovery method combining extraction and azeotropic distillation

A technology of azeotropic distillation column and dilute acetic acid, which is applied in chemical recovery, separation/purification of carboxylic acid compounds, etc., can solve the problems of high energy consumption, uneconomical, and increased vapor-liquid phase load of the system, and reduce steam consumption , reduce energy consumption, reduce the effect of content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

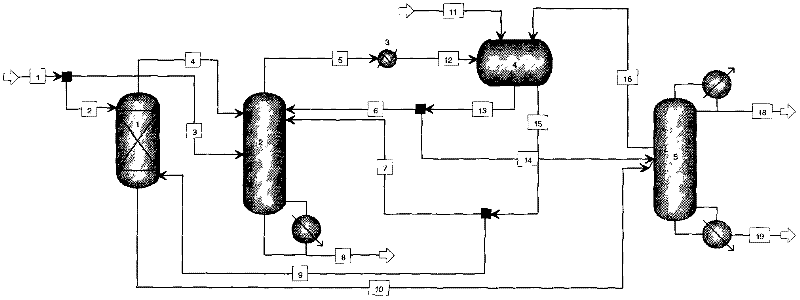

[0025] For the specific flow chart of the embodiment, please refer to figure 1 , the material composition in the present embodiment is based on mass fraction.

[0026] In the mixture stream 1 to be separated, the injection rate of dilute acetic acid is 29225 kg / h, the mass fraction of acetic acid is 0.15, and the mass fraction of water is 0.85. Stream 2, as a part of stream 1, is extracted in the upper part of the extraction tower with a flow rate of 10000kg / h; stream 3 is another part of stream 1, which directly enters the azeotropic distillation tower for heterogeneous azeotropic distillation , the flow rate is 19225kg / h.

[0027] The extraction tower 1 adopts a packed tower, the theoretical plate number of the extraction tower 1 is 30, the selected operating condition is normal temperature 25°C, and the stream temperature can also be selected as 40-50°C, and the operating pressure is generally atmospheric pressure.

[0028] Stream 9 is the extraction agent required for ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com