Fuel oil condensing boiler reverse-balancing heat efficient measuring method

A measuring method and technology of thermal efficiency, which are applied in the field of measuring the reverse balance thermal efficiency of oil-fired condensing boilers, and can solve problems such as lack of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

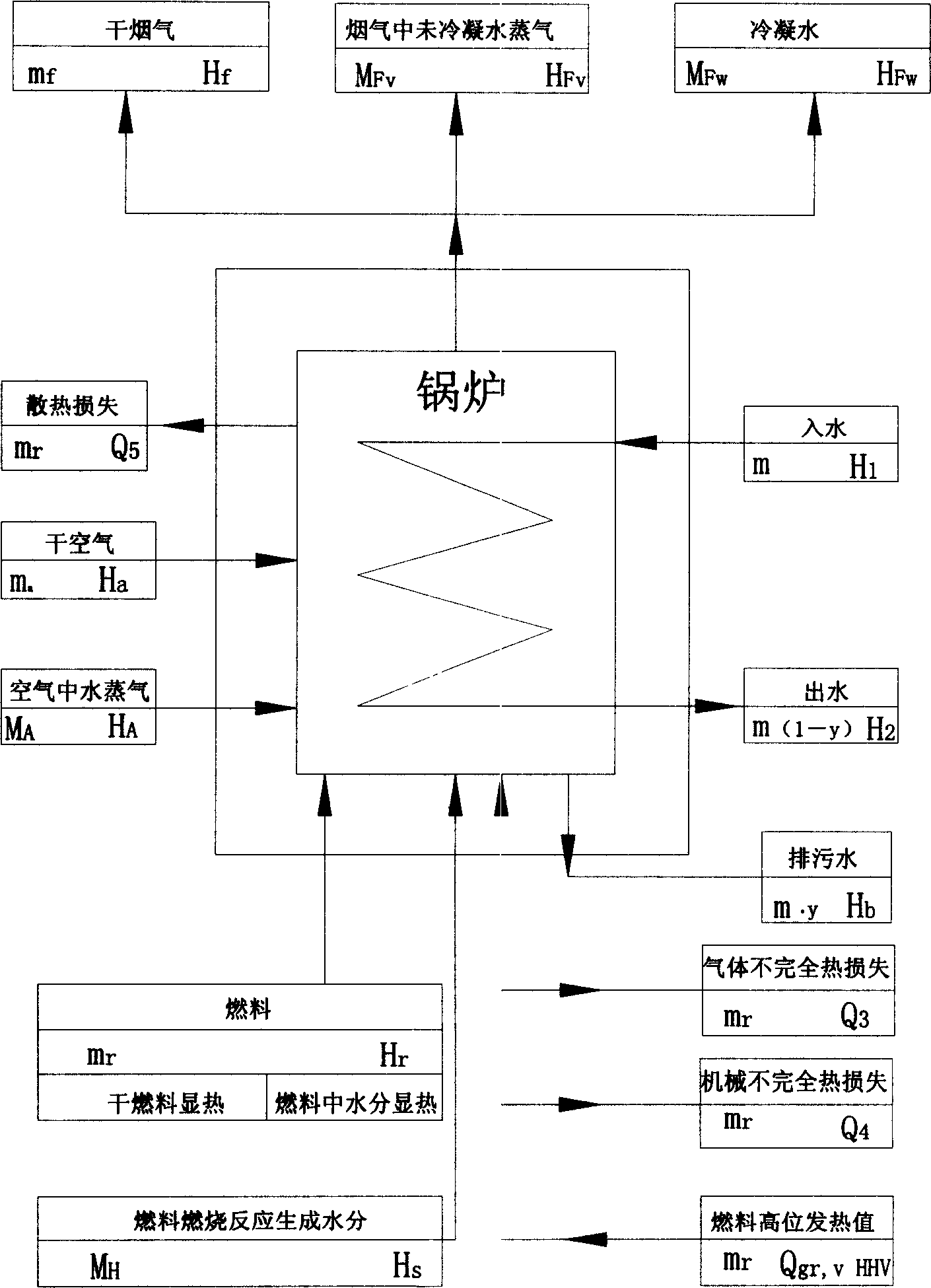

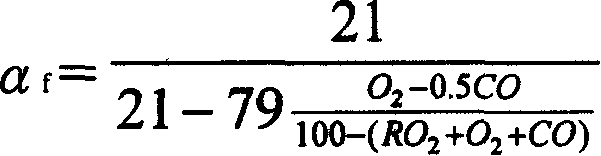

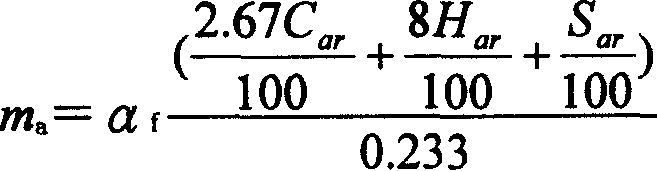

Method used

Image

Examples

example

[0165] The known data and setting parameters of air and fuel (200 heavy oil) are shown in Table 1;

[0166] Table 2 shows the exhaust loss composition and thermal efficiency measured by the present invention.

[0167] After obtaining the thermal efficiency of the condensing boiler, the fuel consumption can be obtained according to the specific boiler capacity or heat supply, and a series of subsequent thermal calculations can be performed.

[0168]

Fuel

Symbol

Quality share

High post

Calories

Fuel consumption

Consumption

C ar

H ar

S ar

N ar

M ar

Q gr,v

B

Value

83.98

12.23

1.0

0.2

2.0

44662

0.056

Air

Symbol

Relative

Overdose

Coefficient

Saturation pressure

Force

Overheated

Water steam

Saturated

Water enthalpy

Dry air

Constant pressure ratio

Hold ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com