Heat supply device capable of recovering aqueous vapour latent heat in fuel gas, fuel oil boiler flue gas

A technology for oil-fired boilers and heating devices, applied in steam generation, feed water heaters, heat pumps, etc., can solve the problem of flue gas falling to the condensation temperature, achieve efficiency improvement, and be beneficial to environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

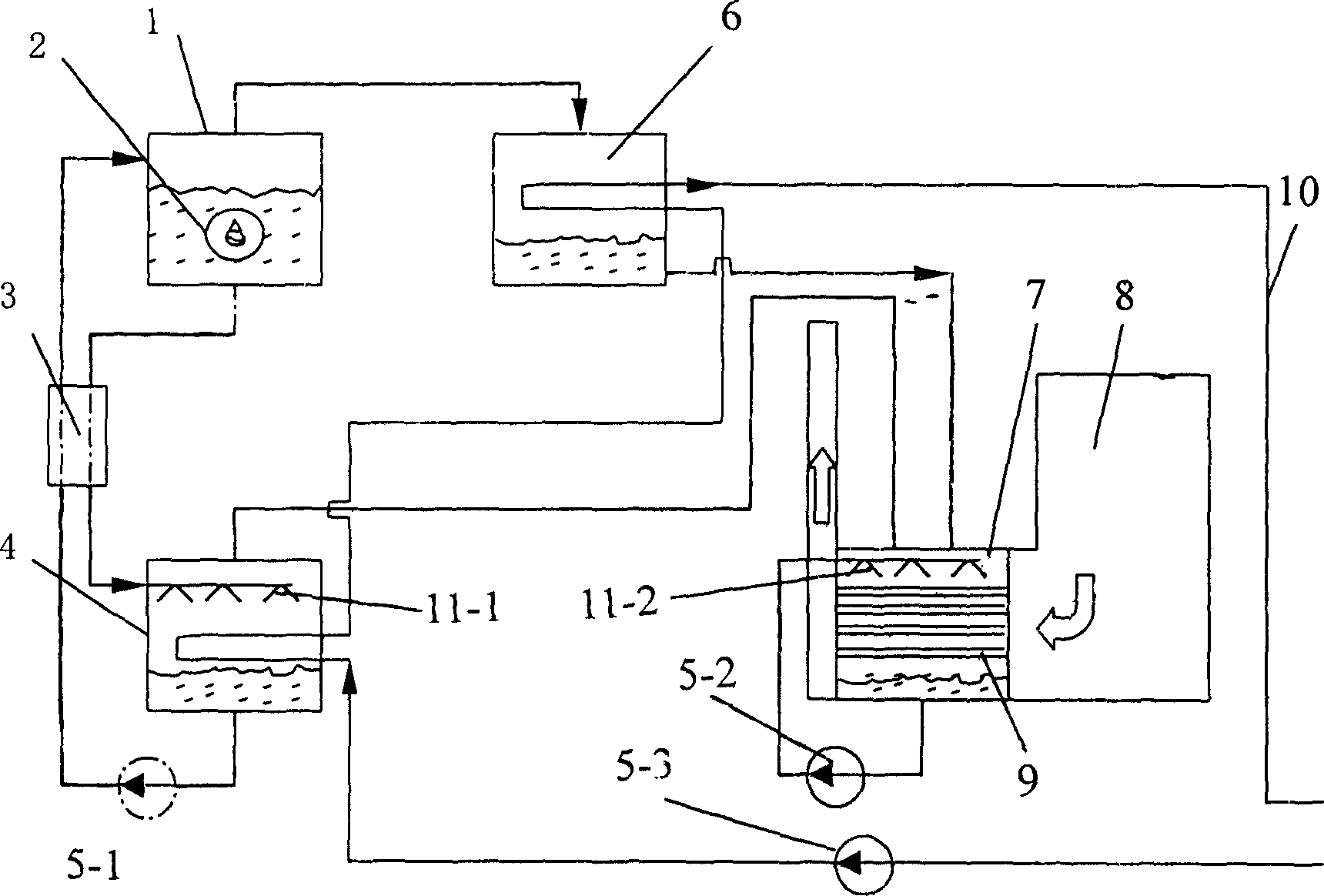

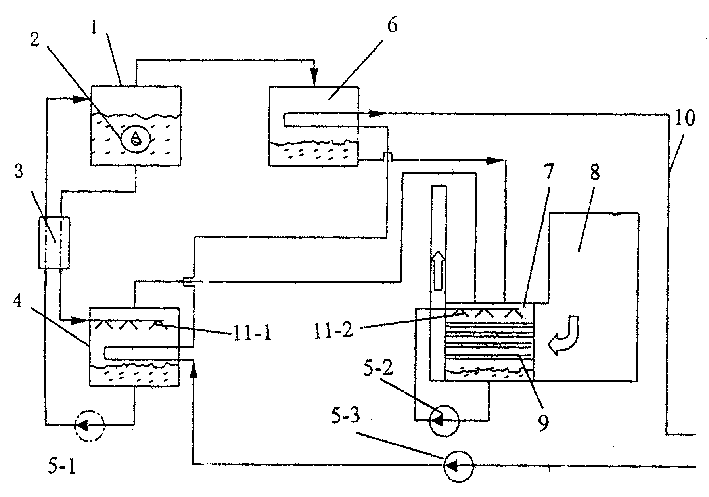

[0013] This embodiment takes a single-effect absorption heat pump as an example. Such as figure 1 As shown: the absorption heat pump is composed of a generator 1, a solution exchanger 3, an absorber 4, a condenser 6, an evaporator 7 and connecting pipes. A combustion chamber 2 is arranged inside the generator 1, and the periphery of the combustion chamber 2 is a sealed solution chamber. Combustion chamber 2 heats the working medium on its periphery to decompose refrigerant vapor and high-concentration absorbent; the upper part of the solution chamber of absorber 4 is provided with a nozzle, and the nozzle and the bottom of the solution chamber are respectively connected to the generator 1 through the connecting pipe. The sealed chamber communicates and forms a circulation loop, and a pump 5-1 is arranged on the connecting pipe at the bottom of the solution chamber of the absorber 4 . The pump 5-1 is used to inject the working fluid in the absorber 4 back into the generator 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com